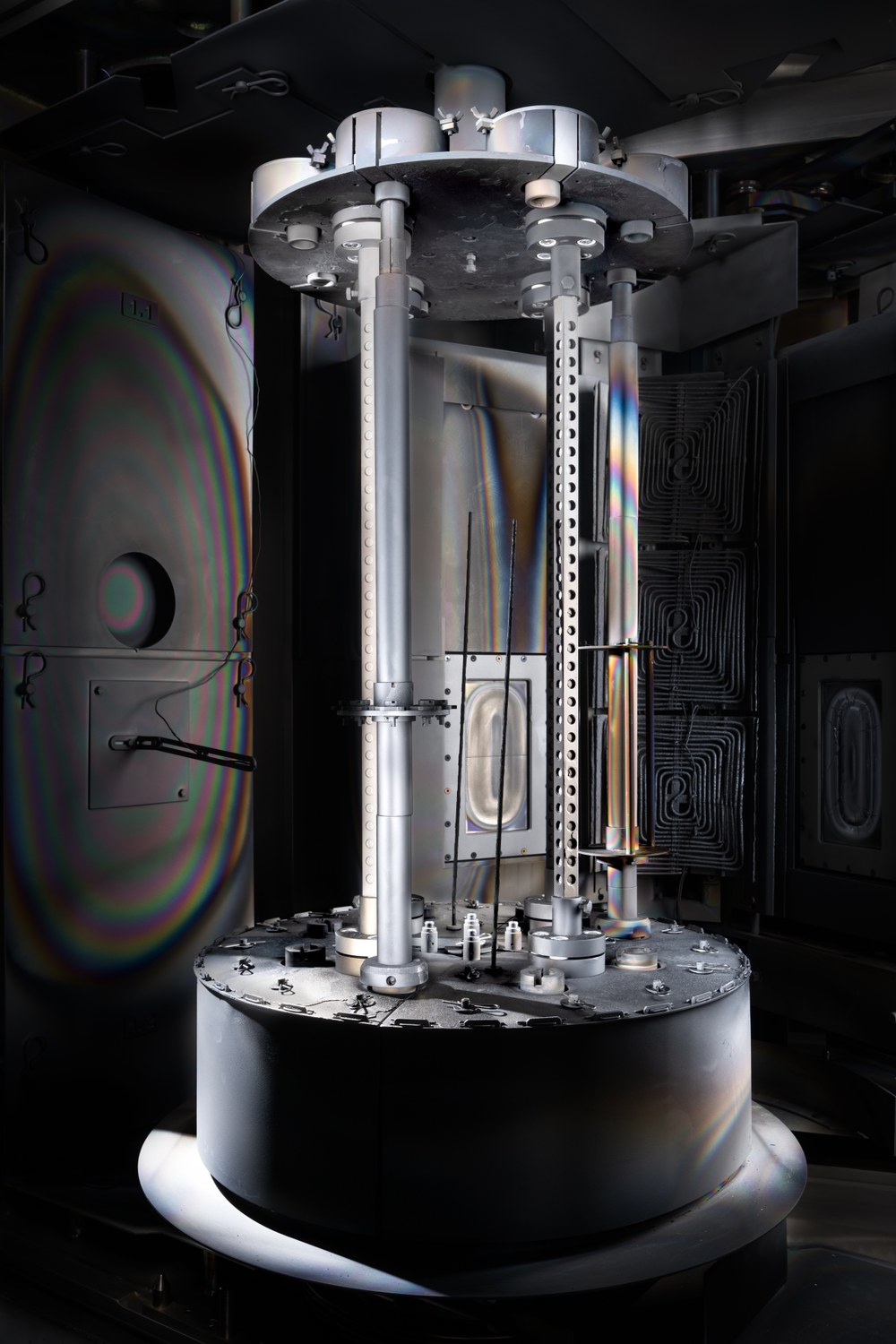

Multisource magnetron sputtering system

The MEGA coating system (multi-source magnetron sputtering system) enables the production of new types of metallic or ceramic coatings in monolithic, graded or multi-layer arrangements using 7 different coating sources.

The MEGA system combines the advantages of different coating technologies: classic DC magnetron sputtering, reactive (co-)magnetron sputtering, high-frequency sputtering, hollow cathode gas flow sputtering and arc PVD. The integration of a sputtering process monitor, which measures the composition and concentration of the particles in the gas phase during the coating processes, enables the control and reproducibility of the highly sensitive, reactive (co-)sputtering processes in particular. An additional, controllable magnetic field can also be used to control the ionisation of the particles and ultimately adjust the coating morphology individually.

By means of an integrated arc PVD module, coatings can be produced using an arc discharge process, which are characterised by high hardness values and increased adhesion in conjunction with a high coating rate, e.g. as wear protection coatings.

In gas flow sputtering, a metal target is used as a hollow cathode, which is removed over a large area by a hollow cathode discharge. The sputtered material is transported in atomic form from the hollow cathode to the substrate surface by a strong argon gas flow, where it is deposited at a high coating rate. This process can also be used to coat components with complex geometries.

Different sample positions in the coating chamber allow different, multi-layer coating systems to be obtained from one coating process. In addition, a combinatorial approach can be used to obtain different layers in terms of their chemical composition from one process run, which is particularly advantageous in the course of rapid materials development.

System characteristics:

- pulsed DC and RF sources in parallel operation up to 500 mm in length and 12 kW supply power each

- reactive (co-)magnetron sputtering- GFS source with 250 mm opening height- integrable arc PVD module- substrate BIAS: DC/DC pulsed/RF; additional ionisation through controllable magnetic field (booster)

- 8 planetary positions with triple rotation (planetary gear) or rotation in front of a source

- variable loading: large components (prototypes) or many small samples

- innovative microstructures, new layer properties, variable layer composition (especially metals, intermetallic compounds, oxides, nitrides)

- max. component size Ø 400 mm*550 mm; 600°C substrate temperature

- state-of-the-art process monitoring via sputtering process monitor