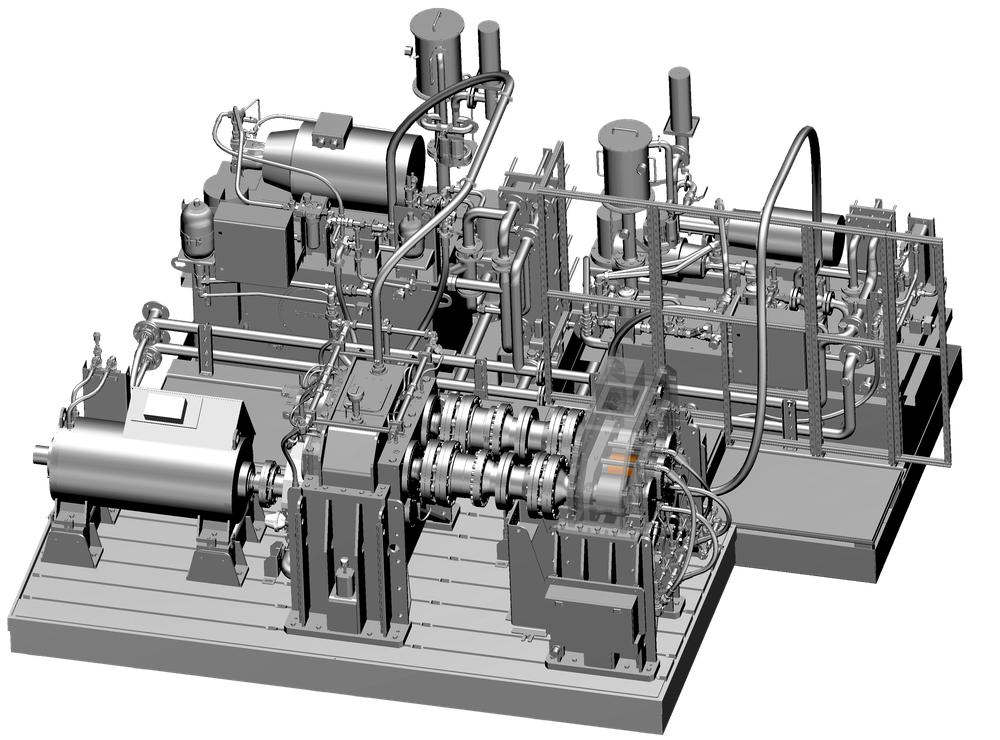

Commissioning of the new gear loading test stand GRACE

The new test stand GRACE is currently undergoing the final phase of commissioning at the German Aerospace Center (DLR) and will thus be available for gearbox load testing. This unique test stand enables DLR to conduct research on gearwheels for gearboxes in airplane engines under engine-representative operating conditions. The test stand makes detailed investigations of crack propagation and reliability possible. It was designed and built by the German company RENK Test System in Augsburg, Bavaria. The Federal Ministry for Economic Affairs and Climate Action subsidised the creation of this new research facility within the framework of the federal aviation research programme. The test stand was designed for specific research campaigns and operating cases in cooperation with Rolls-Royce Deutschland.

Airplane engines increasingly rely on gearboxes to decouple the rotational speed of the fan at the engine’s inlet from the rotational speed of the driving turbine at the engine’s outlet. This improvement raises the efficiency of airplane engines and thereby reduces their fuel consumption.

GRACE stands for Gear Crack Experiment, which hints at the goal of the first test campaign on the test stand – to investigate crack propagation. For this purpose, cracks are initiated at certain locations on the gearwheels. The gears are then loaded under realistic operating conditions. The goal is to improve the understanding of the path the crack takes as it propagates. Among other things, the results are compared with simulations of the damage in order to validate the simulation methods.

The test stand is able to subject the gears to high loads. Torques of up to 23,000 Nm and rotational speeds of up to 4,500 rpm are possible. This results in a value of over 10 MW of transferred power.

In a follow-on test campaign on this test stand, the reliability of gearwheels will be investigated. Undamaged gears will operate for a certain amount of time under overload conditions, i.e. at higher rotational speeds and torques than expected during real-life operation. The objective is to confirm that the gears will operate as expected without damage under these conditions.

The research results obtained on this unique test stand will flow back into industrial development. They form part of the foundation to use these gears in further research on a research airplane (a flying testbed).

DLR