Test Facility

The Test Facility at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) DLR Institute of Composite Structures and Adaptive Systems in Braunschweig is used for comprehensive, quality-assured determination of the mechanical characteristics of fibre-composite materials, as well as rapid evaluation of new materials and structural technologies.

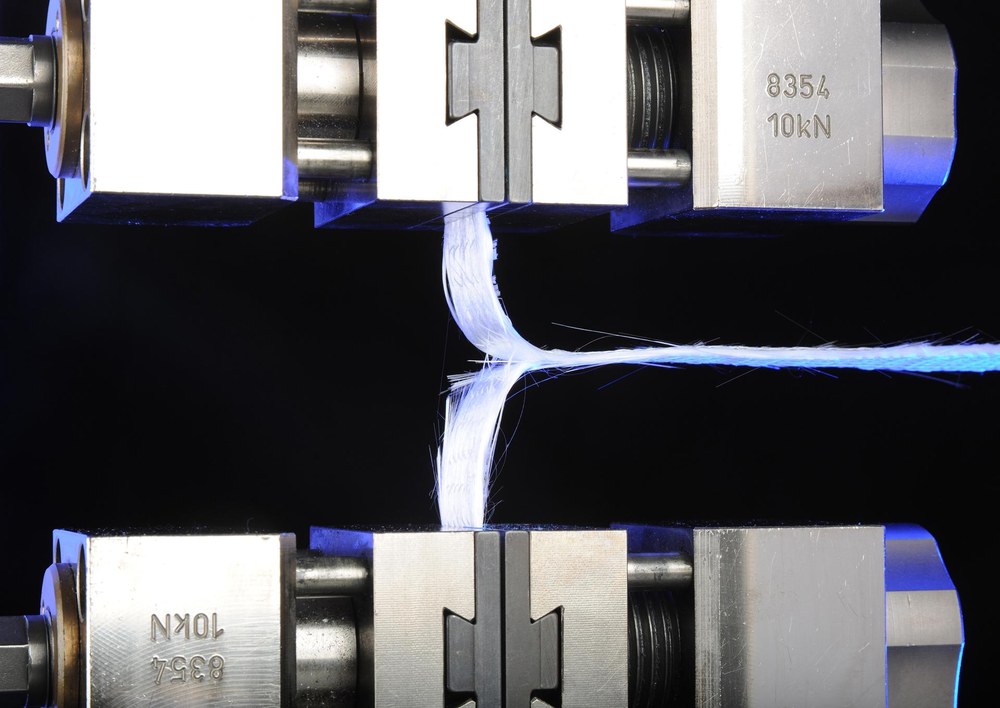

Fibre-composite materials test system determines contaminants and service life

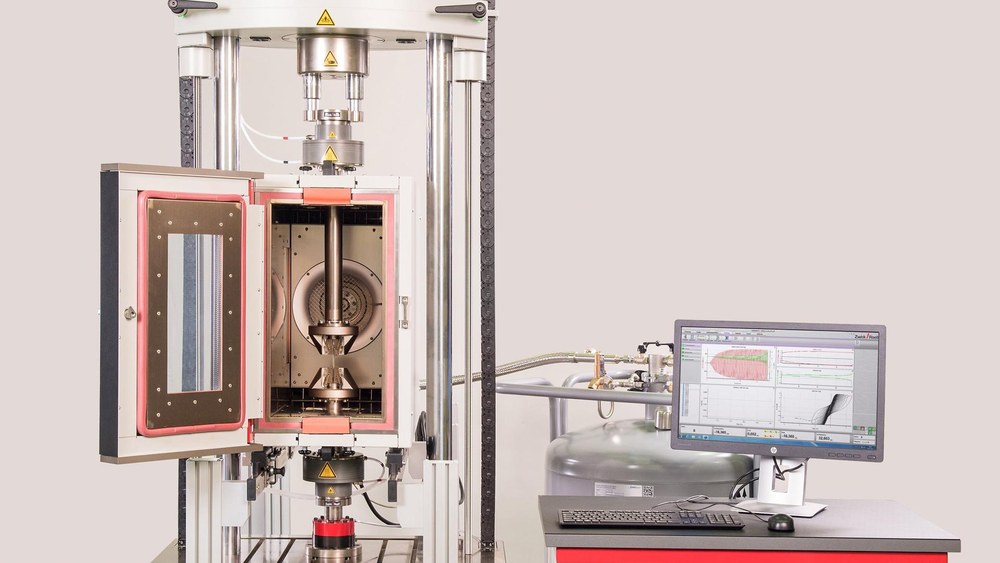

For fibre-reinforced composites produced in a primary forming process, the capability to inspect the quality of the laminate non-destructively is crucial. The Test Facility makes it possible to determine both static and dynamic characteristics over a wide range of forces. The research completed here also serves to determine the service life and fatigue resistance of materials and structures, as well as to evaluate the damage tolerance of fibre composites.

In addition to standard testing, the flexible test rigs and specialist testing facilities (such as the buckling test machine), offer a range of further research options. Supplemented with optical measurement technologies, the geometrical and dimensional accuracy of fibre-composite components can also be investigated, which is of particular significance for assembly processes (for example, tolerance chain management). Parameters for efficient process control can be defined with the help of the comprehensively equipped thermal analysis laboratory.

The research laboratory is Airbus-certified and DIN ISO 17025-accredited, which makes the static testing facilities particularly attractive to clients in the aeronautics industry, as well as underlining the Institute’s focus on quality.