Next Generation Train (NGT)

Since its inception in 2007, research into the Next Generation Train (NGT) has resulted in a high-speed passenger transport concept that aims to link major European cities or major airports using the NGT HGV (high-speed train). The NGT HGV travels at 400 kilometres per hour and has a capacity of around 800 passengers.

To reduce average travel times in areas near high-speed rail lines, a 230-kilometre-per-hour feeder service, the NGT LINK, will connect to these lines. Given the cost considerations, rail transport in Europe predominantly operates as mixed transport, making high-speed rail particularly appealing for moving time-critical goods. To design a suitable rail vehicle, insights from the NGT HGV are being applied to an ultra-high-speed freight train, the NGT Cargo, with the aim of developing a quiet, operationally flexible railcar-based freight train.

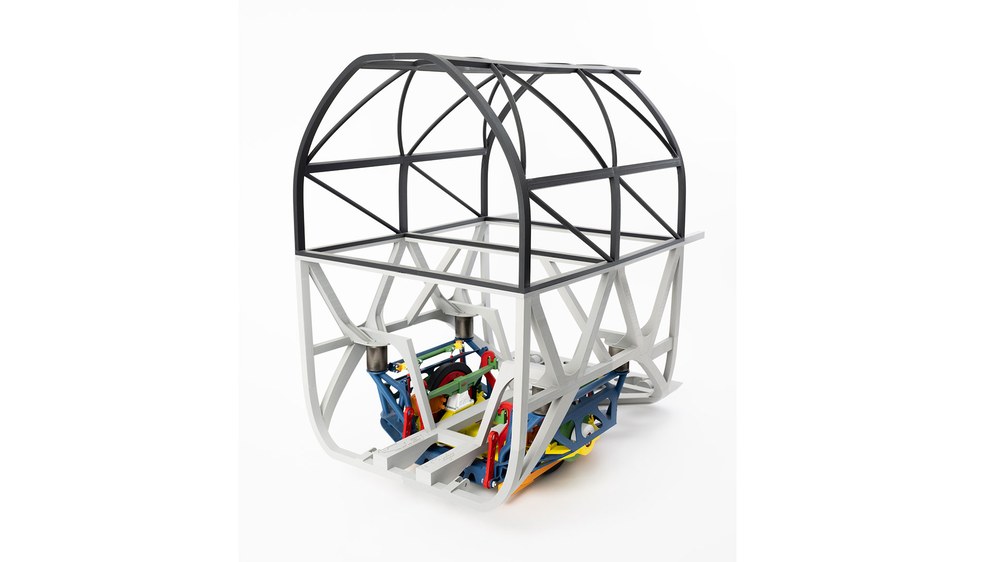

A new, lightweight, single-wheel independent chassis is being developed for a double-decker ultra-high-speed train. This chassis will be tested on DLR's internal test stand in Oberpfaffenhofen, at external test facilities and in real-world rail test runs.

Achieving these goals relies on incorporating and optimising the dynamics of the 'wheel-rail' system.

Systemhaus Technik has produced a 1:5 scale model of the chassis using FDM (Fused Deposition Modelling) technology, with adapted geometries and revised 3D print files. For demonstration purposes, individual assemblies in the model were colour-coded.

Systemhaus Technik is integrating the suspension of the wheel carrier with leaf springs and sensor technology to measure movements and loads on the chassis. Key challenges include the existing chassis design, limited installation space combined with high load requirements, and production constraints, especially for the large welded frames.

Systemhaus Technik is collaborating on this project with the DLR Institutes of Vehicle Concepts and System Dynamics and Control.