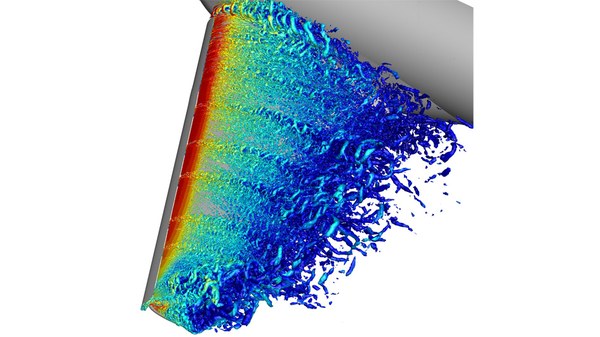

ADaMant NASA half model

The NASA half model is being modified by the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) in order to develop and demonstrate suitable physical models for high-precision flow simulations on industrially relevant wing configurations, thereby pushing the limits of the flight envelope. This process involves designing and constructing a special flow nacelle with a pylon, a wing leading edge and a vented foldable bullnose Krueger (VFBK) leading-edge flap, including mounts.

For the first time, Systemhaus Technik at the DLR site in Braunschweig is producing components using the selective laser sintering process (SLS) for use in a cryogenic wind tunnel. These requirements dictate that the strength of the material used must be verified in accordance with NASA specifications.

These specifications require tensile and impact tests at room temperature and under cryogenic conditions of minus 196 degrees Celsius.

The model is being measured both in the NWB (low-speed wind tunnel) at DLR Braunschweig and in NASA's cryogenic wind tunnel, the National Transonic Facility (NFT), in Hampton, Virginia.

The model is manufactured using the SLM 3D printing process, allowing complex geometries (inner channels for the pressure measurement holes) to be produced in one operation. This eliminates many additional steps, such as machining slots and drillings for pressure measuring tubes and hoses, while simultaneously increasing stability.