EVo – a research platform for the automated production of large quantities of contoured components

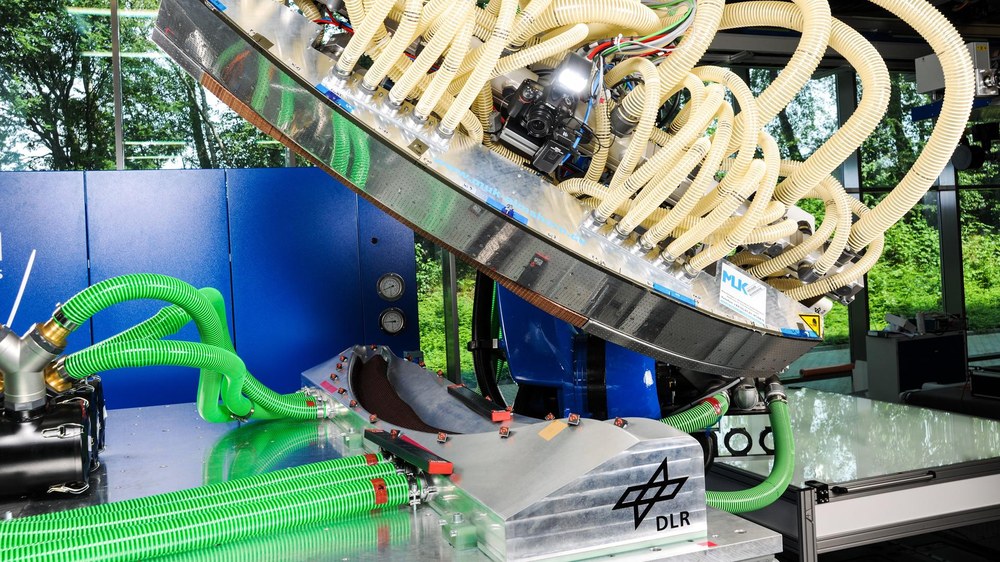

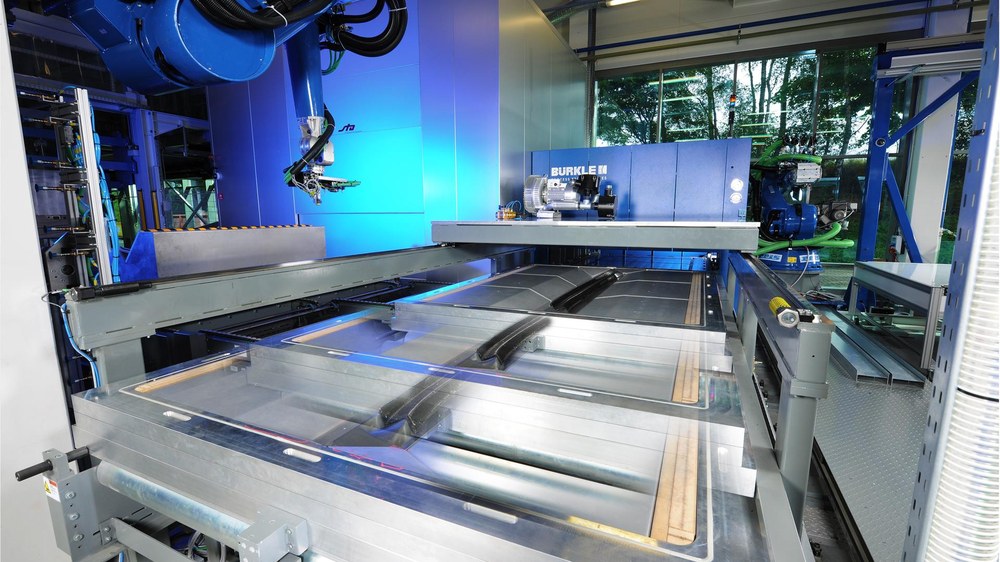

The EVo research platform is based at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) Center for Lightweight-Production-Technology in Stade; it is used for fully automated and flexible production of fibre-composite components using Resin Transfer Moulding (RTM) technology, with an upstream preforming process.

This large-scale research facility at DLR's DLR Institute of Composite Structures and Adaptive Systems focuses on the production of carbon-fibre-reinforced primary aerospace structures. In addition, the facility is used in the development, integration and testing of quality assurance systems and new production technologies for the manufacture of fibre-composite materials.

Automated production chain for complex fibre-composite components

Semi-finished fibre materials (fabrics and scrims) made from carbon or glass, as well as epoxy resin systems, can be processed at the facility. The maximum component dimensions are 2.5 by 2 by 0.5 metres. The primary applications include structural components for aircraft fuselages (rib segments), wings (ribs), and the empennage (ribs). There are many different variants of such components, which means that there are many similar but few identical components per aircraft.

In principle, production of automotive components or structures for public transport vehicles can also be demonstrated, although the feasible cycle times and precision of the platform are designed for aerospace applications. The platform is increasingly being used as a testing platform for digitalisation and Industry 4.0. In addition to component manufacturers, material suppliers, end users and system manufacturers, the platform is also gaining interest among providers of Internet of Things (IoT) solutions.