LUMEN – AI-assisted reusable rocket engines

Pangea Aerospace

The German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) is taking a significant step in the development of reusable space transportation systems with its innovative LUMEN project. The focus of LUMEN (short for Liquid Upper Stage Demonstrator Engine) is an engine fuelled by a combination of liquid oxygen and methane – considered to be a promising option for future rocket engines. On the one hand, this combination could significantly reduce the cost of rocket engines and, on the other, create the technical basis for future reusable space propulsion systems. At the DLR Institute of Space Propulsion in Lampoldshausen, an engine with 25 kilonewtons of thrust is currently being developed and tested, from its individual components to the overall system.

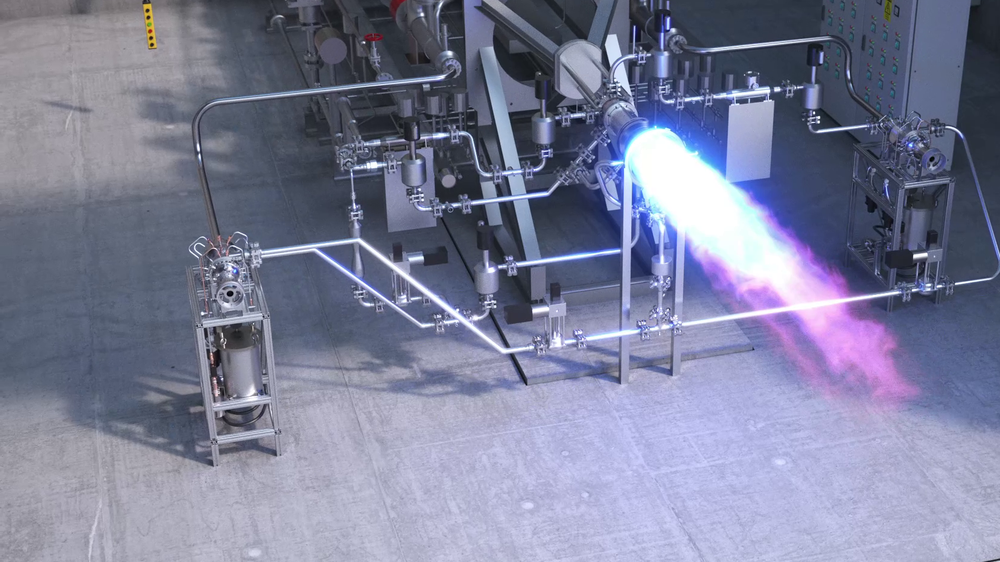

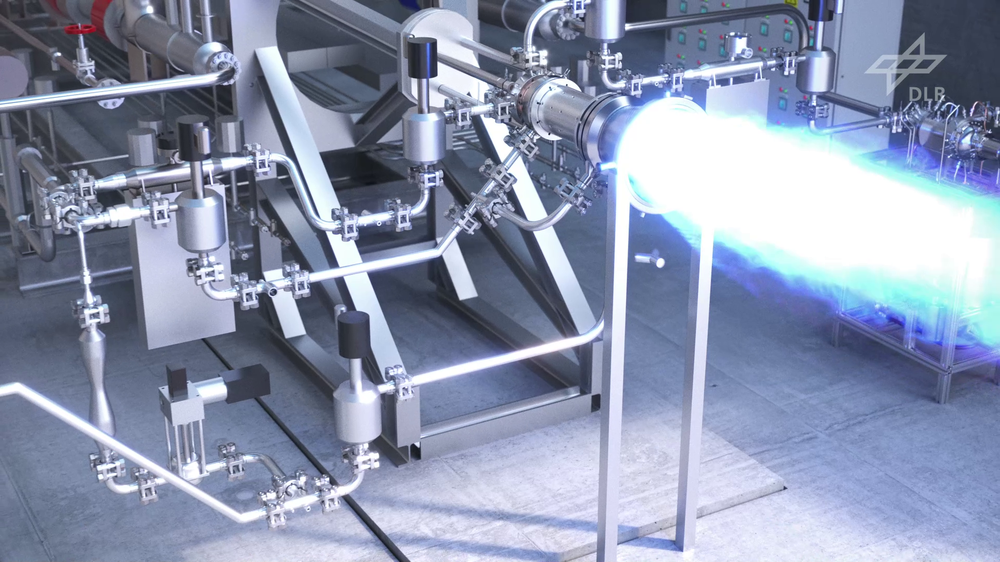

The LUMEN project encompasses the design, manufacture and operation of a demonstrator for a cryogenic upper-stage engine. The demonstrator's design is optimised for test bench operations, ensuring excellent measurement accessibility to all individual components and so enabling the investigation of any problems that may arise within the overall system. Invaluable data can be obtained that provides a far deeper understanding of the engine’s operating behaviour than is possible on real flight engines or during single component tests.

Animation: Technologiedemonstrator LUMEN

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

The LUMEN demonstrator not only provides detailed insights into the engine's operating behaviour but supports, among other things, the development of technologies for laser ignition or AI-based control and monitoring systems, both of which are essential for reusable rocket engines. Additionally, the collected measurement data serves as the basis for the validation of numerical simulation methods to describe liquid propulsion systems.

The idea behind LUMEN is not only to gain valuable insights for DLR's own research but also to create a platform for companies and start-ups from the German and European space industries to test their innovations in a real-world environment at DLR. The project helps to promote the transfer of research results into practical industrial applications.

The challenge of multiple ignition

Travellers waiting for their flight at the airport gate know this: preparing an aircraft for take-off takes time. The plane needs to be refuelled, unloaded, reloaded and thoroughly cleaned. The time required is manageable, and no one expects the engines to be laboriously dismantled, and new ones fitted before each flight. This is understandable, because aircraft engines have a life span of several thousand ignitions. Rockets, too, rely on engines for propulsion, though they are different in their design and proportions. Traditional rocket engines are built for a single launch: they ignite once to launch, and any further ignition has not yet been envisioned for conventional ‘one-way’ rocket stages, as they burn up during re-entry through Earth's atmosphere.

Another reason why multiple ignitions is tricky for rocket engines is that they are subjected to completely different forces and environmental conditions, making the development of reusable rocket engines a particular challenge. Every component, from the smallest hose connection to the valves and the outer casing, are exposed to higher stresses than any other engine and have to perform even better. A rocket engine is exposed to microgravity, extreme temperature fluctuations and increased space radiation. For this reason, entirely new concepts must be devised for multiple ignition propulsion systems for the reusable launchers of the future.

The potential of artificial intelligence in rocket engine development

A central aspect of the LUMEN project is the integration of artificial intelligence (AI). DLR researchers are employing artificial neural networks to model complex processes such as heat transfer within the cooling channels of the combustion chamber. This approach allows for more accurate predictions and is many times faster than traditional computational fluid dynamics calculations.

Another use case for AI in LUMEN is engine control. Rocket engines are highly complex systems, operated at the very limits of what is technically possible. As a result, it is challenging to develop control algorithms that have a broad range of applications, while optimising the thrust or fuel consumption of the engine. DLR has taken the first steps towards developing a system to optimise control of LUMEN. Various components have been developed that rely on artificial intelligence, one such involving the control of LUMEN's turbo pump, with subsequent developments extending to control of the entire engine. Another element is to improve the robustness and reliability of AI-based controls by incorporating physical knowledge and estimating uncertainties. But the technology goes much further, by, for example, using AI to detect combustion instabilities before they occur. These instabilities can destroy an engine in fractions of a second, so preventing them is crucial. In the future, all these AI-based components will be combined to create an intelligent engine controller capable of operating the engine optimally. This will not only extend the rocket engine's service life but also enable it to respond autonomously to unforeseen events.

Expansion of the DLR P8 test bench in Lampoldshausen

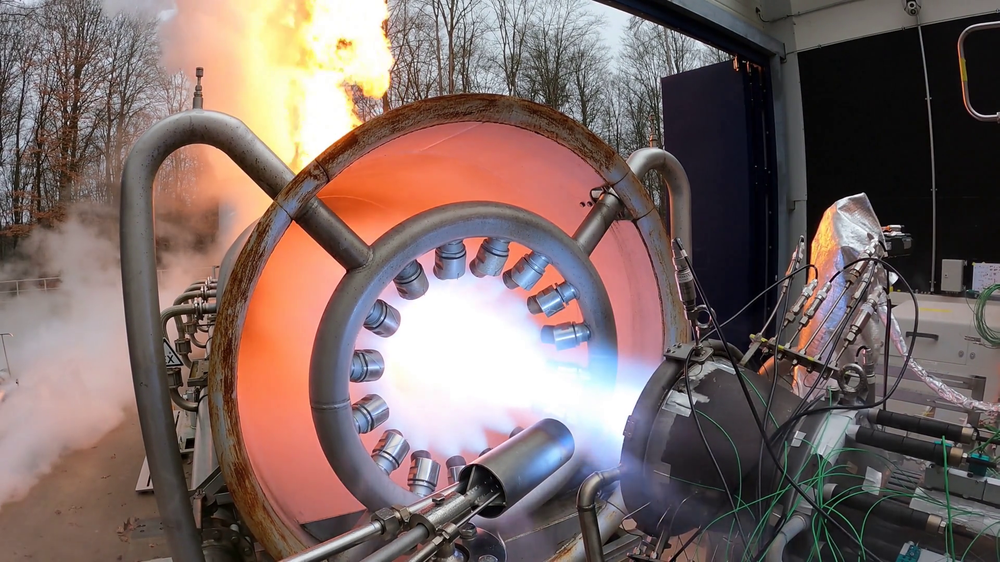

To support the development and testing of new rocket propulsion technologies, the European research and technology test bench P8 at the DLR site in Lampoldshausen, Baden-Württemberg, has undergone significant expansion. In 2021, the new P8.3 test cell began operations, allowing for the testing of turbopumps and entire rocket engines – an upgrade of the existing P8.1 and P8.2 test cells only capable of testing combustion chambers.

The expansion of P8 is the result of collaboration between DLR, the French space agency CNES and ArianeGroup. The facility aims to enhance the transfer of knowledge from research to practical applications and to provide new momentum for the development of sustainable space propulsion systems.

DLR's partnership with CNES and ArianeGroup is a key step in preparing for future European launch vehicles – another example of successful European collaboration in spaceflight.

In addition, the P8 test bench is extensively utilised by numerous European start-ups to advance their rocket engine technologies.

LUMEN demonstrator successfully tested

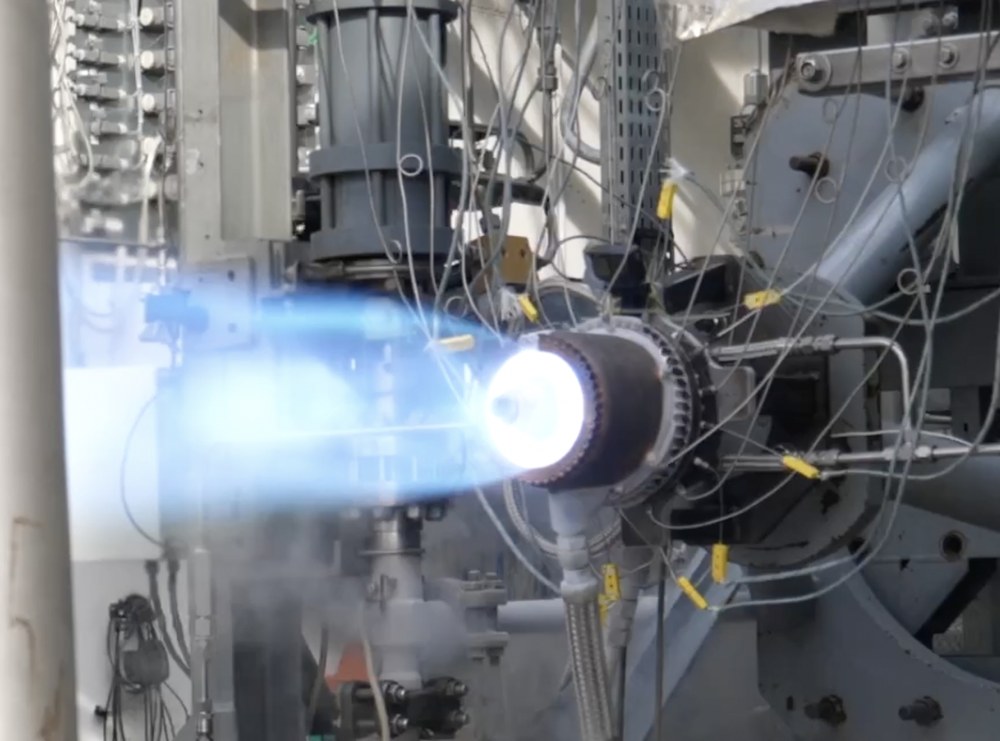

In March 2024, the LUMEN demonstrator – the first rocket engine developed at DLR – was successfully put into operation at the P8.3 test bench. LUMEN is also the first methane-fuelled engine designed in Germany, showcasing DLR's innovation and technical capabilities.

These tests mark a significant step forward for the project, allowing precise, rapid and cost-effective examination of the engine's components – from the combustion chamber and turbo pumps to individual valves – and how they interact.

Video: DLR researchers successfully test the interaction of individual components of the LUMEN demonstrator

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

Future prospects and sustainable space exploration

The development of sustainable and reusable space propulsion systems is a key focus at DLR's Lampoldshausen site. An important step is being made towards climate-compatible space exploration, supported by the 'Zero Emission – Hydrogen Site Lampoldshausen' project and along with the production of green hydrogen. This reflects DLR's long-term vision of not only pioneering advanced technologies but also ensuring their sustainability.

The LUMEN project shows how cutting-edge technology and international cooperation can shape the future of spaceflight. By combining artificial intelligence, advanced testing infrastructure and sustainable energy solutions, DLR is laying a strong foundation for the next generation of space propulsion systems.