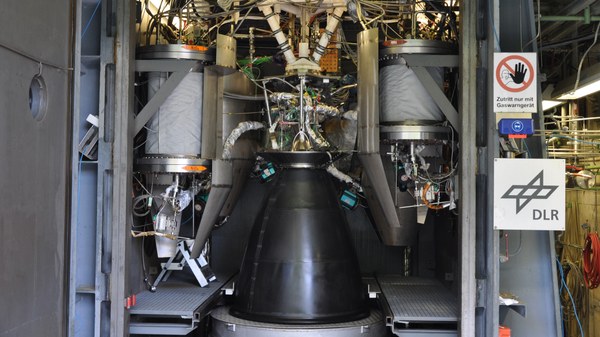

High-Altitude Simulation Test Bench P4

After the lower stage of a rocket burns out and is ignited on the ground on the launch pad, rocket upper stage engines are used at altitudes of around 50 km above the earth's surface. There, the air pressure has already dropped to around 0.2 percent of its value at sea level (1013 millibars). The task of an high-altitude simulation test facility is to provide this ambient pressure of around 2 millibars for the ignition of the engine and to maintain it even when the engine is running. Engineers refer to such pressure values as a vacuum. In order to determine whether an upper stage engine will ignite reliably under these conditions and function smoothly in a vacuum, it must be tested accordingly before a mission. In particular, the ignition behavior of the engine is examined, the thermal load on the structures is analyzed and the vacuum thrust is measured.

Altitude simulation

- Long-term vacuum tests

- Steam-operated vacuum system

- Tests under ground conditions

Test positions

Rocket steam generators

The steam required to operate the vacuum system is provided by a total of five rocket steam generators developed at the DLR site in Lampoldshausen, which are operated with alcohol and liquid oxygen. The steam leaves the steam generators at a pressure of 22 bar and a temperature of 210 degrees Celsius. The steam is then accelerated to supersonic speed in the ejectors of the vacuum system, drawing the combustion gases from the engine out of the vacuum chamber. All five steam generators together develop a thermal output of 650 megawatts. The tank capacities are designed for an operating time of 1,000 seconds.