Hydrogen Peroxide and Injection

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

In order to replace conventional storable propellants, such as hydrazine-based propellants, alternative and advanced propellants are required which, in addition to the necessary performance characteristics, also improve aspects such as storability or health risks. Highly concentrated hydrogen peroxide is a promising alternative. The department of Satellite- and Orbital Propulsion develops and tests propulsion systems based on hydrogen peroxide. Hydrogen peroxide is investigated as a single propellant component in a monopropellant engine or as an oxidizer in a bipropellant engine. Among a large number of possible fuel combinations with hydrogen peroxide as an oxidizer, fuels, that can also replace conventional fuels, are primarily used. Among others, research into hypergolic fuel combinations based on hydrogen peroxide as an oxidizer and ionic liquids as fuel, is conducted. The implementation of hydrogen peroxide-based propellants is demonstrated in the various monopropellant and bipropellant engines under atmospheric and vacuum conditions and the engine and combustion chamber processes are investigated in order to expand the limits of the operating conditions.

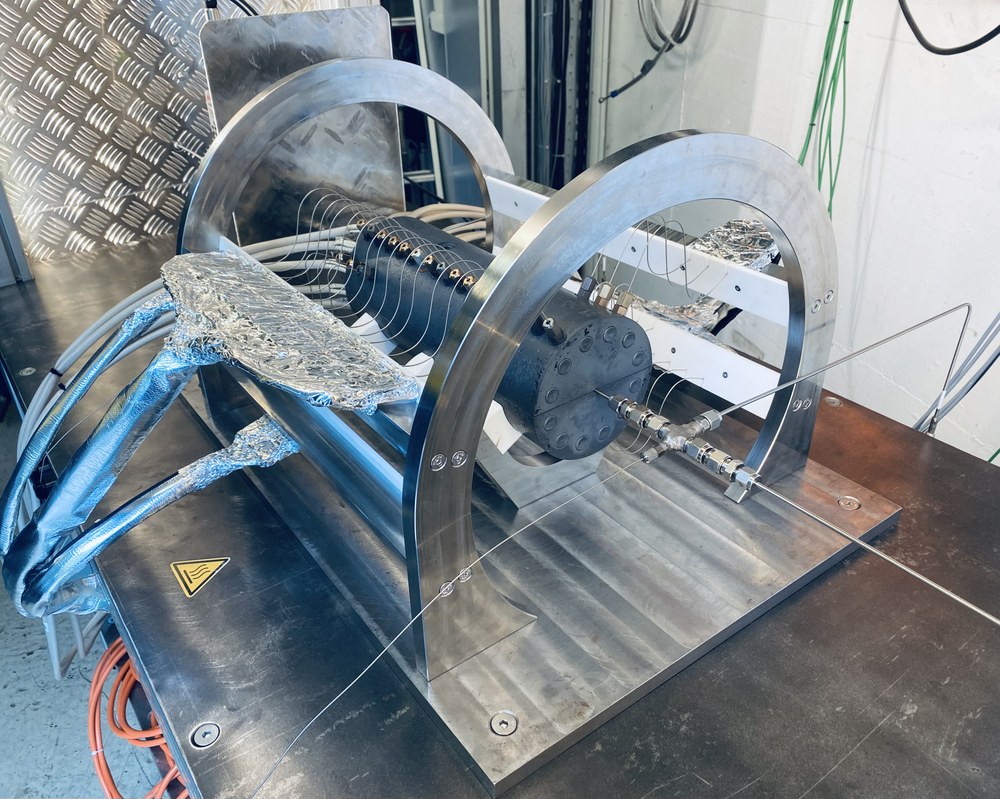

A major challenge in the implementation of new propellants in advanced engines is the development of the engine components, as the design of conventional engines and components cannot cover the new properties and parameters. The department of Satellite- and Orbital Propulsion is therefore conducting research into engine subsystems such as propellant supply, injection, cooling and the combustion chamber using advanced materials and production methods. In particular, active cooling with hydrogen peroxide as a coolant in various cooling concepts, such as film and regenerative cooling, is being investigated. The objectives of research into hydrogen peroxide include a deep understanding of the processes in the engine and the development of new engine components to enable a wide range of applications for hydrogen peroxide in space propulsion systems.

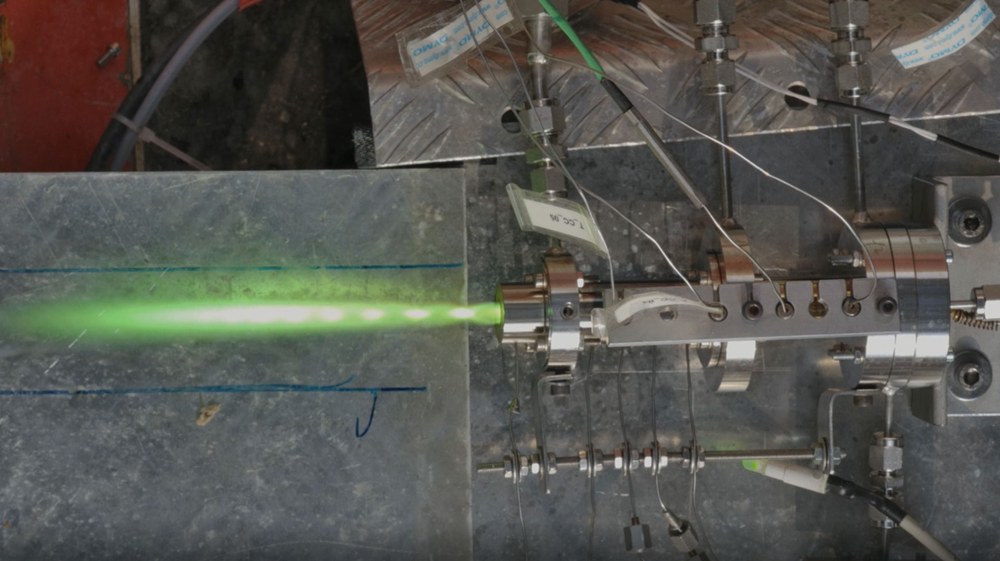

The injection of propellants into the combustion chamber is an essential step for the combustion chamber processes. Propellant preparation has a significant influence on the processes in the combustion chamber, which is why an in-depth understanding of the injectors and the resulting sprays is necessary. Various injector types are being developed and analyzed in the department of Satellite- and Orbital Propulsion for this purpose. The influence of injector geometry, injection conditions and rheological properties on the flow and spray behaviour is investigated in detail on a test bench for cold flow investigations. Using optical measurement technology, different spray phenomena are detected and subsequently interpreted. In addition to the basic investigations with non-reacting media under atmospheric conditions, investigations are also carried out under adaptable ambient conditions, such as increased ambient pressure or vacuum. The objectives of the research on injection include the development of new and propellant-optimized injectors, a deeper understanding of injection phenomena and the transfer of cold flow measurements to the hot gas engine.