Diagnostic & Support

Diagnostic & Support

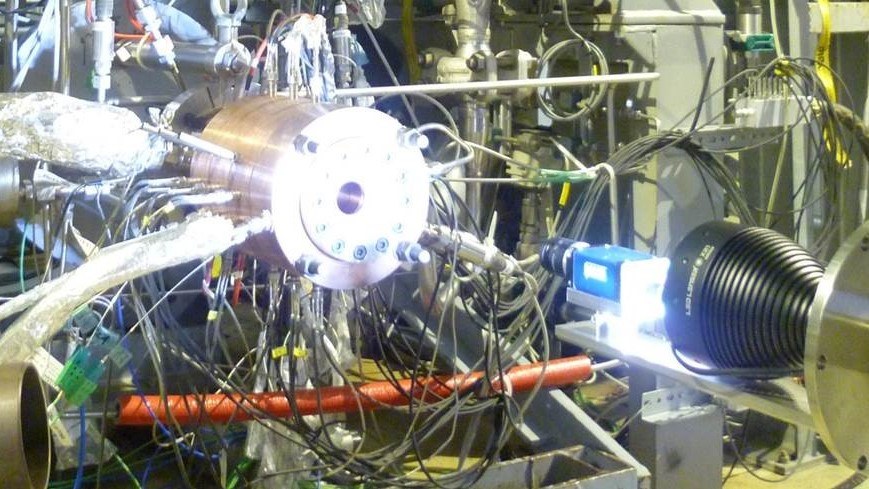

This research setup on the P8 test stand is used to visualize ignition processes in a rocket combustion chamber.

Credit:

The importance of non-contact optical diagnostics has increased continuously in recent years. Modern camera systems and highly developed laser-based processes make a significant contribution to the tests on our research and large-scale test benches.

The "Diagnostic & Support" group adapts and develops measurement methods for a wide range of applications, from rocket engines and hydrogen technologies to laboratory applications.

Our range of services includes the following measurement methods:

- High-speed imaging

- Ultraviolet visualization

- Classical schlieren visualization

- High-speed shadowgraphy

- Thermography

- Optical combustion chamber probing

- Background Oriented Schlieren (BOS)

- Emission/absorption spectroscopy

- Laser-induced breakdown spectroscopy (LIBS)

- Plasma spectroscopy

- Interferometry

- Digital image processing

The following technical aids are available:

- High-speed cameras for images with up to 2.1 million frames per second,

- image intensifiers (residual light amplifiers) for visualizing phenomena invisible to the human eye, such as light emission in the ultraviolet range,

- infrared cameras for thermographic diagnostics,

- high-resolution optical spectrometers for ultraviolet to infrared wavelengths,

- lighting technology in the high-performance range.

Our methods for the scientific investigation and evaluation of optically acquired data are now briefly described below:

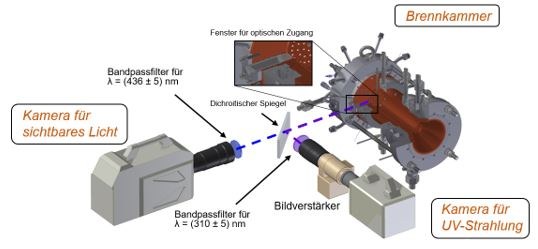

Setup for simultaneous high-speed visualization in the visible and ultraviolet wavelength range

Flow phenomena and chemical reaction sites can be visualized.

Credit:

- High-speed visualization of dynamic processes using shadow and emission images: Fast-moving processes and transient processes can be captured and analyzed using modern digital high-speed cameras. These include various phenomena with high temporal resolution, such as the propagation of flames after ignition in a rocket combustion chamber, the dynamics of jet decay during the injection of liquid oxygen into the combustion chamber or the behavior of a flame in a strong acoustic field. High-speed cameras provide image sequences consisting of a large number of images. Automated image processing routines are used to extract quantitative information about the observed processes from these image sequences. For example, the speed of droplets in a flow can be detected or the propagation speed of a flame front during the ignition process can be determined.

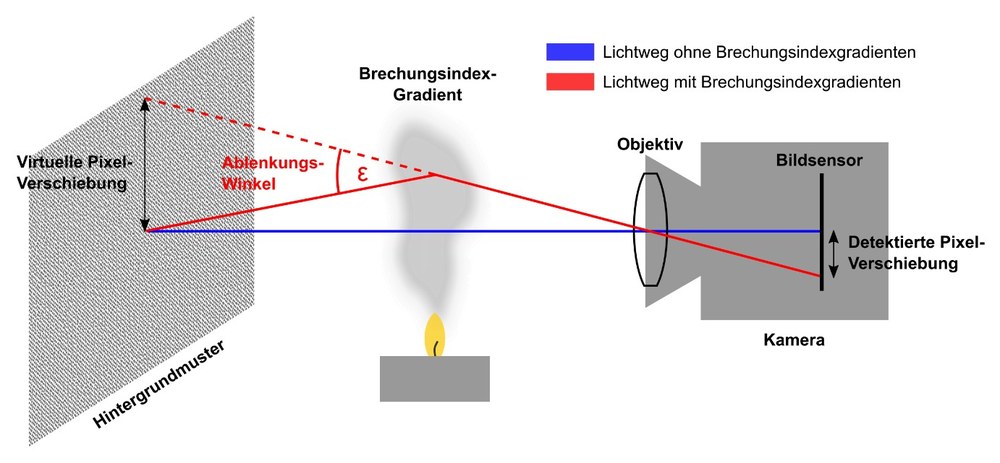

How the background-oriented streaking technique (BOS) works

Various properties such as density, temperature or material composition in a flow field can be visualized.

Credit:

- Flow visualization using classical and background-oriented schlieren (BOS) techniques: Various properties such as density, temperature or material composition in a flow field can be visualized. These are usually qualitative measurements of these variables, but recording their spatial distribution provides essential information for assessing the flow and mixing processes. Different fluids, density and temperature changes in a flow field can be visualized with the associated differences in the refractive index. Various methods such as schlieren and shadow photography or the transmitted light method are used. The combustion chambers are fitted with windows to ensure optical access to the flow field.

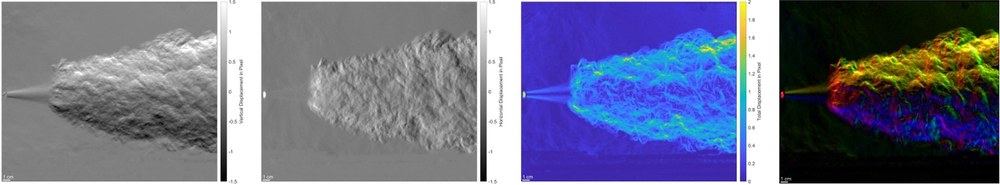

Flow visualization using classical and background-oriented streaking (BOS) techniques

Various options for displaying schlieren images to optimize the visual impression of hydrogen-oxygen combustion.

Credit:

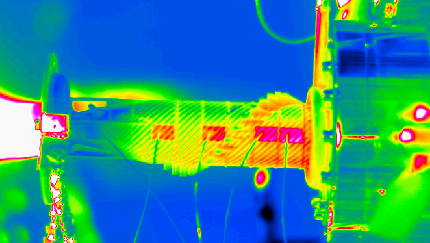

- Thermography using high-resolution thermal imaging cameras: Thermal radiation from surfaces can be used for both temperature determination and flow visualization. The high temperatures and high pressure in combustion chambers lead to high thermal stress on the combustion chamber structures. The infrared radiation emitted by hot surfaces can be used to determine the surface temperatures and track the thermal load on the components during operation. As the heat transfer from the hot gases to the wall depends on the gas flow, infrared thermography can also be used to investigate the flow condition near the wall. This method is used in particular to assess the transient flow in expansion nozzles.

Visualization of the temperature distribution on an experimental combustion chamber

The infrared radiation from hot surfaces can be used to determine the surface temperature.

Credit:

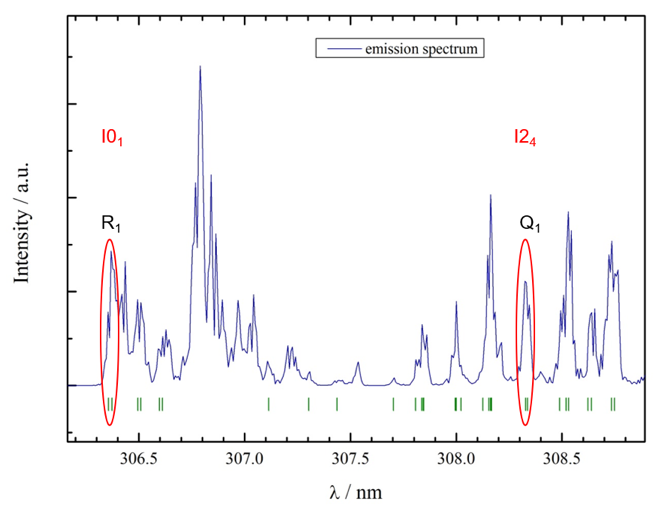

- Flame temperature determination with high-resolution (sub-nanometer) emission spectroscopy: In addition to light in the visual and infrared range, flames also emit radiation in the ultraviolet wavelength range, i.e. in the non-visible range. Using so-called spectrometers, this radiation can be visualized as intensity over wavelength. The high resolution of wavelengths in the sub-nanometer range provides insights into important physico-chemical processes and can be used, for example, to determine flame temperatures or mixing ratios (ratio of fuel to oxidizer). In addition to classic emission or absorption spectroscopy, laser-induced spectroscopy methods such as laser-induced plasma spectroscopy (LIPS) are also used.

Flame temperature determination with high-resolution (sub-nanometer) emission spectroscopy

The diagram shows the emission spectrum of the combustion reaction of hydrogen and oxygen.

Credit:

Kontakt

Dr. Justin Hardi

Head of Department

German Aerospace Center (DLR)

Institute of Space Propulsion

Rocket Propulsion Technology

Im Langen Grund, 74239 Hardthausen

Germany