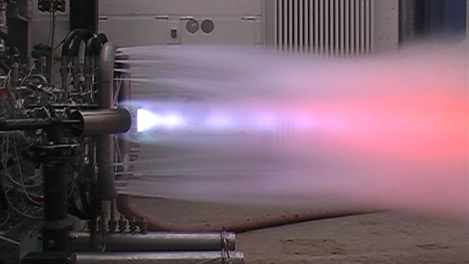

Thrust Chamber Technology

In addition to increasing performance, the greatest demand on modern launch systems is to increase reliability and increase service life while simultaneously reducing production and operating costs. In order to significantly increase the effectiveness, performance and specific impulse of future rocket engines, high combustion chamber pressures are required above all. If the combustion chamber pressure is increased in order to increase the performance of the engine, the energy density also increases and, accordingly, so does the thermomechanical load on the combustion chamber structure. A high temperature difference between the hot gases in the combustion chamber and the cooling medium in conjunction with high heat transfer coefficients lead to an extremely high level of heat flux density through the combustion chamber wall. For example, the typical heat flux density values for the Vulcain engine with a combustion chamber pressure of 10.5 megapascals (MPa) are up to 80 MW/m2 and for the space shuttle main engine at 20.5 MPa up to 160 MW/m2.

The reliable operation of rocket combustion chambers under these extreme thermal and mechanical loads is mainly ensured by effective cooling. For an optimal design of the cooling system with minimum hydrodynamic losses, the exact knowledge of the heat transfer as well as the combustion processes is of very great importance. The importance of these issues is evident from the fact that the reliability of engine life estimation is essentially dependent on the accuracy of wall temperature determination. For example, an error of 40 Kelvin will result in a 50 percent reduction in service life. Because most components are already stressed to the material limit, a serious improvement in cooling and material behavior are decisive criteria for the further development of space transportation systems.

The thrust chamber technology research group deals with the design, construction and manufacture of the research combustion chamber, including the following aspects:

- Layout and design of cooling systems for rocket thrust chambers and implementation and development of modern design algorithms to optimize these cooling systems (methods such as SAPR (System for Automatic Project Planning) and artificial intelligence methods are used),

- Investigation of the applicability of new production processes, The applicability of new production processes, such as additive manufacturing and new materials for the manufacture of cooling systems for space propulsion systems, and their influence on the design of rocket thrust chambers,

- Experimental determination of heat transfer in thrust chambers and corresponding development of measurement methods for determining thermal loads and the parameters of heat transport processes in rocket thrust chambers,

- Numerical simulation of heat transport processes in rocket thrust chambers and their components; Verification and further development of layout and design tools,

- Investigation of atomization and mixing of cryogenic propellants under high pressure conditions,

- Development of new injection processes (such as API injector concept),

- Optical investigation of propellant preparation,

- Determination of the influence of atomization and combustion processes on thermal loads and investigation of the atomization of cryogenic propellants under space conditions.

Among other things, the research group's activities support the implementation of test campaigns for engine demonstrators on the European Research and Technology Test Bench P8 and the Research Test Bench P6. The focus here is on the best possible use of test bench capacities and the use of statistical methods to optimize the test program in order to reduce development costs. To increase the accuracy of temperature measurements, a cryo laboratory is available in which cryogenic measurement technology is developed and calibrated for the temperature range up to 4.3 Kelvin.