The stuff of sustainable spaceflight

Although it's only been on the market for a few months, InSpacePropulsion Technologies has a decade of impressive DLR research behind it. Lukas Werling and Felix Lauck hope that their start-up will make spacecraft propulsion more sustainable, reduce costs and replace toxic propellants currently used. If everything goes as planned, a propulsion system developed by them will be tested in space for the first time next year.

Felix Lauck and Lukas Werling have always been fascinated by spaceflight, starting with toy spaceships, 'pulp' magazines about space heroes and stargazing at their local astronomy club. "In the late 1990s, someone from DLR gave a talk about Ariane 5 at the astronomy club," says Lauck. "That's when I first learned just how sophisticated rocket engines are." It was a similar story for Werling, who recalls that: "Pretty much everything I built as a child was somehow related to spaceflight." Both now in their mid-30s, that interest has not waned. In fact, it has led them to establish their own company, InSpace Propulsion Technologies.

The fuel conventionally used for spacecraft is hydrazine, a chemical compound made up of nitrogen and hydrogen. Hydrazine is powerful and reliable, but it is also highly toxic. Anyone who works with it must wear a full protective suit with its own air supply, making fuelling operations both complicated and expensive.

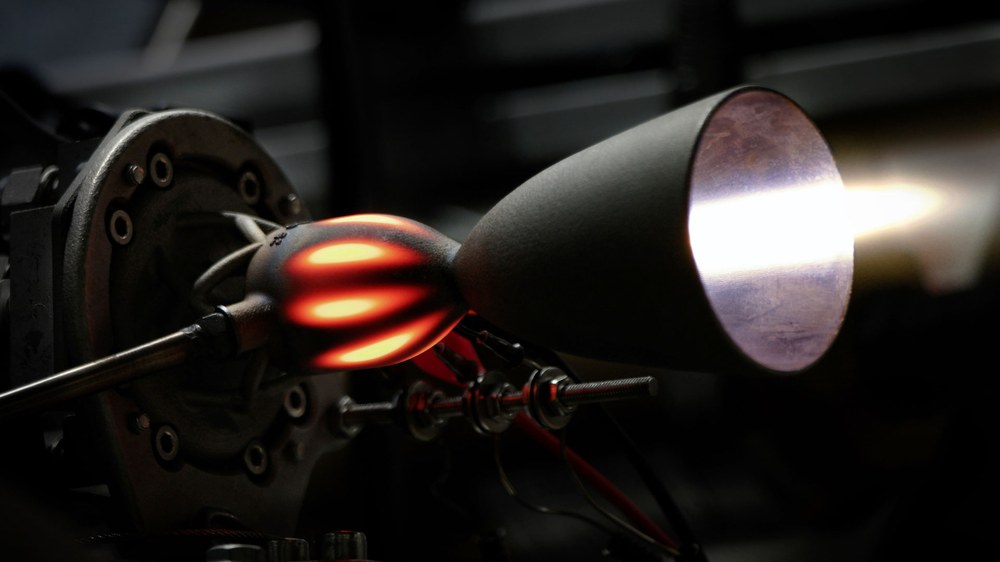

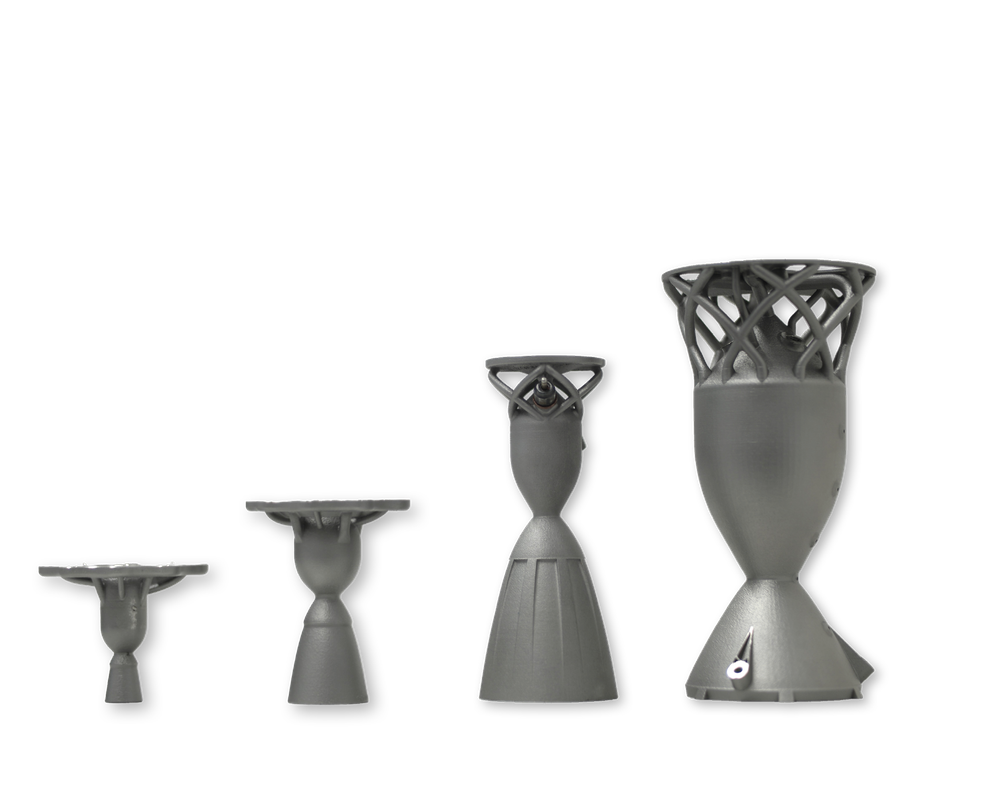

Lauck and Werling have been researching alternatives to hydrazine at the DLR Institute of Space Propulsion in Lampoldshausen since 2011. The new propellants have to be non-toxic, easier to handle than existing ones and less complicated to test. In the space industry, these are referred to as 'green propellants'. Werling has developed the 'HyNOx' technology based on nitrous oxide and ethane, which has been tested and improved thousands of times at the DLR test stands in Lampoldshausen. "The fuel is especially well suited to smaller spacecraft, such as CubeSats," says Werling. These small satellites are often as small as a shoebox.

Lauck's doctoral thesis is about a second new propellant 'HIP_11', which has been patented by DLR and is suitable for larger spacecraft such as capsules or landers. In HIP_11 hydrogen peroxide and a molten salt react with each other. The propellant ignites as soon as the substances come into contact with each other – a property of propellants described as 'hypergolic'. HIP_11 stands for 'Hypergolic Ionic Liquid Propellant developed at M11'. "My doctoral thesis is almost finished, so HIP_11 will soon be flying into space," says Lauck. "It's a very special moment."

The first test in space

InSpaceTechnologies still has to overcome the hurdle of getting into space for the first time. "Most customers require an in-orbit demonstration," says Werling. For this reason, the start-up got in touch with the Curtin University in Perth, Australia, which is planning missions with a CubeSat. Together, they got down to business. InSpacePropulsion Technologies will not only supply the HyNOx propellant to thrust the Australian CubeSat but also the 3D-printed engines, tanks, electronics, valves and interfaces. The CubeSat could launch as early as next year.

In 2023, InSpacePropulsion Technologies also won a flight on a small satellite as part of DLR's Small Satellite Payload Competition. This provided the company with a free satellite platform and a flight on a European microlauncher. The flight is planned for 2025.

From research to reality

How did the two scientists come to form their own company? "There's a lot happening right now in the New Space sector, which is focused on the commercialisation of spaceflight," says Werling. "Our green propellants can play an important role here, and we offer the right thrusters, too. After years of research and development, we want to see our technology actually fly."

The transfer from research to application is a key area of concern for DLR. Spin-offs like InSpacePropulsion Technologies demonstrate this to impressive effect.

DLR supports researchers who want to commercialise their ideas. The DLR_Startup Factory supports them throughout the entire start-up process. As a research institution, DLR does not bring products onto the market, instead developing technologies up to a certain level of maturity. In principle, this can extend right up to the moment the technology is proven to work, at which point industrial companies may get involved or employees can start their own companies. This is what happened with InSpacePropulsion Technologies. "The transfer from research to application is a key area of concern for DLR," says Karsten Lemmer, DLR Executive Board Member responsible for Innovation, Transfer and Research Infrastructure. "Spin-offs like InSpacePropulsion Technologies demonstrate this to impressive effect." As such, it is important for scientists to consider the potential industrial use of their research right from the outset. According to Professor Lemmer, figures show that taking this approach is worthwhile: "Our spin-offs are highly successful: some 90 percent hold their own in the market over the long term, which is a very high proportion."

Instant entrepreneurs

With support from DLR and the Helmholtz Enterprise programme, Werling and Lauck analysed the market potential of their research, honed their business idea and embarked on establishing their spin-off. They now present their technology at trade fairs and pitch to potential customers. Life is very busy for the two founders, but they remain grateful for the help they received from the Institute of Space Propulsion and other areas at DLR.

An article by Katja Lenz from the DLRmagazine 175