Does it come in green?

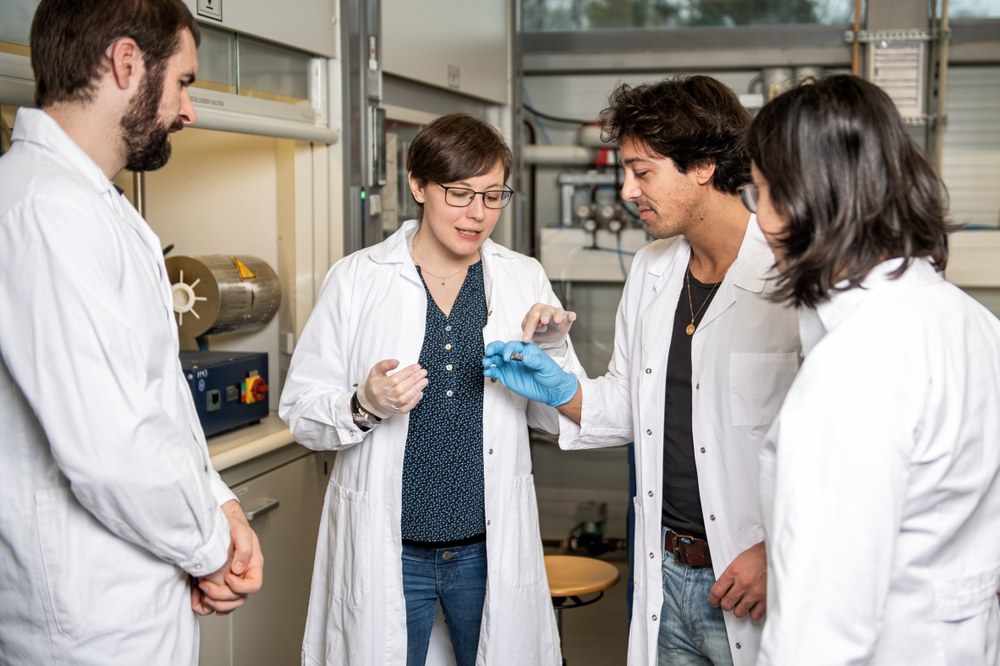

Synthetic nitrogen fertilisers are an integral part of modern agriculture: they increase crop yields and are relatively inexpensive to produce. The problem is that the extraction and subsequent processing of nitrogen are not exactly environmentally friendly. DLR researcher Lena Klaas of the Institute of Future Fuels wants to change all that. The doctor of physics is currently working on a new air separation process in the SESAM project.

Pure nitrogen is a crucial raw material in the chemical industry. One of its uses is to produce fertiliser. In the future, it could also have potential for the decarbonisation of shipping. How is nitrogen traditionally obtained?

Air is made up of 78 percent nitrogen, 21 percent oxygen and one percent other substances. When we remove oxygen from the air, nitrogen remains. This process is called air separation. At present, mainly cryogenic air separation is used: the air is liquefied and then slowly reheated. As each gas has a different boiling point, the gases can be separated from one another in this way.

In the SESAM project, you and your team have developed a thermochemical process for obtaining high-purity nitrogen. How does this work?

At the core of the SESAM project is the reactor that we have developed. This is where air separation takes place. Inside it is a reaction material that can absorb and release oxygen without changing its structure. When we heat this material, it releases oxygen, like a sponge drying out. When our 'sponge' is dry, we cool it down. We then feed air into the reactor, the oxygen collects in our material and what remains is nitrogen, which we remove from the reactor. We reheat the material, the oxygen is released and the process begins again.

That material sounds pretty special.

It really is! It comes from the perovskites family of materials. These are ceramics that share the same basic structure but are actually extremely diverse. To decide on one, we performed a pre-selection using computational methods. Besides having the right physical and chemical parameters, we wanted the material to be non-toxic and inexpensive. We wanted to ensure that it had not been extracted under inhumane conditions, as is often the case with cobalt. I then tested the potential materials in the laboratory. We ultimately settled on perovskite granules made from calcium, strontium and manganese.

One key advantage is that we can produce nitrogen on a smaller scale. In future, fertiliser could ideally be entirely produced on site where it is needed, from start to finish.

Essentially, the SESAM team is introducing a new air separation process. What are the advantages of this?

One key advantage is that we can produce nitrogen on a smaller scale. In future, fertiliser could ideally be entirely produced on site where it is needed, from start to finish. This would eliminate the emissions and losses that currently occur during the transportation of ammonia or fertiliser. From a financial point of view, our thermochemical process is probably more expensive at the moment because it has not yet been established, and it currently requires a similar amount of energy to cryogenic air separation. Theoretically, it should be possible to use electricity produced from sustainable sources for cryogenic air separation, but this is not currently happening everywhere.

The process of converting nitrogen into ammonia and ultimately fertiliser is a very energy-intensive process. Could it be made greener?

The aim is to make the entire process of producing fertiliser carbon-neutral, which involves both air separation and the subsequent processes for producing ammonia and obtaining nitric acid. We started by looking at the beginning of the chain. Our process requires temperatures of up to 900 degrees Celsius. We can save several tonnes of carbon dioxide by generating this heat with solar energy.

Solar energy is limited in Germany. Do we have any alternatives?

Some employees of thyssenkrupp, who worked with us on the SESAM project, came up with the idea of using industrial waste heat instead of solar energy. We then adapted our reactor design so that we could use air as a heating medium.

Was there anything about the project that surprised you?

Yes! We were the first to show that a thermochemical process of this kind can work on a small scale. Producing ammonia requires high-purity nitrogen with an air content of less than 10 ppm – 10 oxygen particles per million nitrogen particles. When we pre-cleaned the air and ran it through our reactor, it came out at 1 ppm – ten times better than our expectations.

What happens next?

We have just started our follow-up project. We will review our thermochemical process and expand our material screening. Maybe we will find a material that is even more suitable. We are working on this with DLR spin-off, ExoMatter. thyssenkrupp will also be involved. We have managed to get the company FGK on board, too. So far, we have only simulated solar heat, but we are working towards running the process in our little solar furnace. I am really looking forward to what lies ahead.

Video: DLR project SESAM – producing high-purity nitrogen with solar energy (in German)

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

This interview was conducted by Julia Heil. An Article from the DLRmagazine 175