Diversity in the tank

What do waste oil, green plants, hydrogen and sewage sludge all have in common? All of these materials can be used to produce sustainable fuels to power the aircraft of the future. Sustainable Aviation Fuels (SAFs) have become increasingly important in air transport over recent years. But what are they, exactly? What sets SAFs apart from conventional kerosene? What role do sustainable fuels play in the decarbonisation of air transport? What is the state of the current research? And what advantages do these potential successors to conventional kerosene offer? This article answers key questions about SAFs.

What are SAFs?

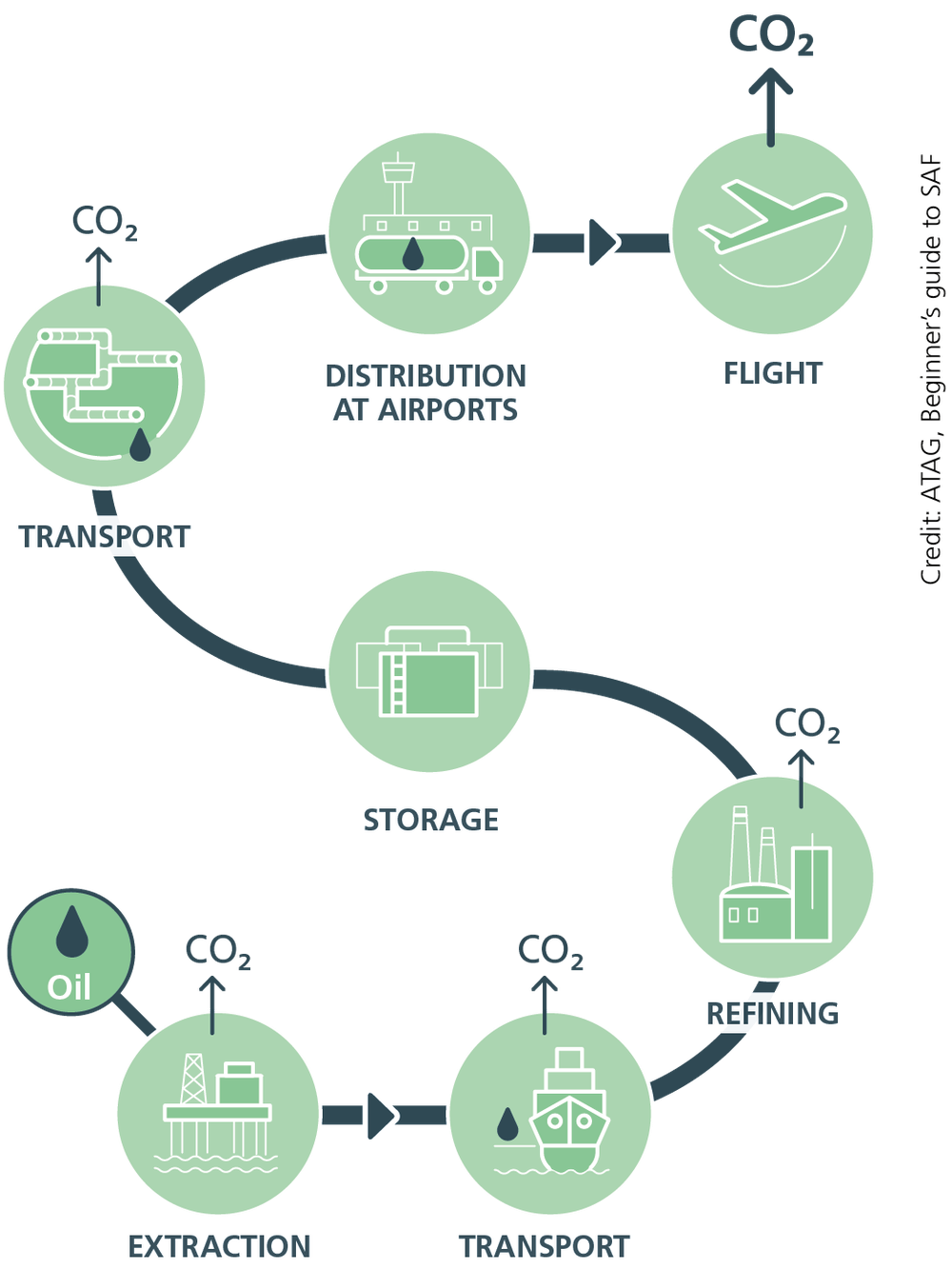

SAFs encompass a variety of sustainable fuels made from very different raw materials. They all have two things in common – they are chemically almost identical to kerosene, but are not based on fossil raw materials, and they have a significantly lower carbon dioxide footprint than kerosene over their entire life cycle (from source to combustion). SAFs are intended to replace fossil fuels in medium and long-haul air transport – areas that are difficult to electrify. The first semi-synthetic SAF, from South African company Sasol, was approved in 1998.

To compare the two, what is conventional jet fuel made of?

Conventional aircraft fuel is a mixture obtained from crude oil through distillation and refining. During the refining process, in addition to kerosene, diesel and petrol are produced. Kerosene contains hydrocarbons such as paraffins, cycloparaffins and aromatics. The aromatics are important for keeping seals elastic, but they produce soot particles during the combustion process, which leads to the formation of contrails that have an impact on the climate. Other compounds that are important for the safe operation of an aircraft are often added to the kerosene, including substances such as antistatic agents, anti-icing chemicals, corrosion inhibitors and substances that improve thermal stability. The specifications do not prescribe how the fuel must be composed, but rather define the physical properties it must have.

Why are SAFs and, above all, synthetic fuels more climate-friendly alternatives to kerosene?

During the combustion process, fossil fuels release the carbon that they sequestered over a long period of time while they were being created. This means that they add to the accumulation of carbon dioxide in the atmosphere and contribute to global warming. In the case of sustainable aviation fuels, the carbon dioxide that could potentially be released upon combustion has been removed from the cycle at an earlier stage due to the use of sustainable resources, thus significantly reducing net carbon dioxide emissions. This is evident from analysis of their life cycle. In addition, many of these new fuels can be designed in such a way that they produce virtually no soot and therefore cause fewer contrails. The production of synthetic, or electricity-based, fuels uses less water and land than the production of biogenic fuels, which are obtained from organic substances. When produced using renewable energy and carbon dioxide from the atmosphere, they can be almost completely carbon neutral, but there is still a long way to go before this can be achieved. The biggest hurdle is energy consumption during production, which remains very high. The necessary capacities have yet to be created.

ATAG, Beginners Guide to SAF

How are SAFs produced today?

At present, there are eight approved manufacturing processes. By far, the largest amount is currently produced using the HEFA (Hydroprocessed Esters and Fatty Acids) process, where the starting materials are (used) vegetable and animal oils and fats, such as the fat from deep fryers. These fats and oils are first hydrogenated. Similar to crude oil, the result can be refined into kerosene. However, this process is not indefinitely scalable, so scientists are working on alternatives. Methanol appears particularly promising.

The multitude of acronyms and scientific terms can be confusing. Which ones are worth bearing in mind for the future?

The term 'Sustainable Aviation Fuels' is decades old – it was coined when people first started the search for alternatives to kerosene. There are now so many non-fossil fuels that there are three generations in their development. The first generation was fuels made from biomass. The second generation uses waste materials of biological origin. HEFA fuels belong to this group. According to current thinking, only synthetic or electricity-based fuels, known as e-fuels, can be scaled sustainably. For that reason, DLR is concentrating on researching, testing and optimising these chemical energy sources. The sun-to-liquid process is being researched in the solar thermal experimental power plant in Jülich. At the Leuna Chemical Park, DLR is setting up a production process for Power-to-Liquid (PtL) fuels on a semi-industrial scale, which is intended to accelerate the market ramp-up of electricity-based fuels.

What other innovations are being worked on?

Austrian oil and gas company OMV has developed the ReOil method, a patented process for extracting crude oil from end-of-life plastic waste. A SAF can be refined from the end product in a second processing step. British start-up Firefly is looking to use the most unusual raw material of all – human excrement. According to Firefly founder James Hygate's calculations, each person produces enough excrement per year to generate four to five litres of SAF. If the UK were to use the entire quantity at its disposal, it could cover at least five percent of its national fuel requirement.

Can SAFs be mixed with conventional kerosene?

At the moment, SAFs can only be used in applications for commercial aviation when mixed with kerosene. A maximum admixture of 50 percent is currently permitted. However, the proportion of actual admixture is less than one percent due to the fact that only small quantities are currently available on the market. From 2025, an initial admixture of two percent SAFs will be required by law for all flights departing from Europe. This admixture will rise to five percent in 2030. The aim is to increase this proportion to 63 percent by 2050 – an important step towards achieving climate-neutral aviation.

ATAG, Beginners Guide to SAF

What is the greatest advantage of SAFs?

SAFs can be specifically designed in the laboratory to ensure low-emission combustion, so that little to no soot particles are produced in the aircraft engines. DLR studies show that when pure SAFs are used, up to 80 percent less soot is released into the atmosphere than with kerosene. This results in fewer contrails. As such, these fuels can make a far greater contribution towards reducing the climate impact than simply curbing carbon dioxide emissions.

Can the amount of SAFs that are being produced today have a positive effect on the climate?

It is not necessary to wait for widespread availability; the benefits from SAFs can be achieved now. DLR researchers have shown that the targeted use of SAFs in regions with a lot of contrail formation has a significantly greater effect than introducing them for all flights. This is because contrails do not appear to the same extent everywhere; there are specific hot spots. These include some of the busiest regions over Europe. To that end, DLR researchers are working on concepts for the 'smart use' of SAFs – for example, specifically in these hot spots. It should be noted, however, that this will require changes to infrastructure on the ground.

Do SAFs only generate less soot during flights, or does this also apply at airports?

Local air quality would also improve at airports if kerosene were gradually replaced by SAFs. This is evident from the initial findings of measurements carried out at Copenhagen Airport as part of an EU research project that measured the emissions from an aircraft fuelled with a mixture containing 35 percent SAFs over a period of several weeks. The data showed a 30 percent reduction in the level of particles.

What is meant by the terms drop-in and non-drop-in?

Drop-in fuels are those that can be used immediately across the entire fleet without the need for any modifications to the aircraft. These fuels are therefore compatible with all engines commonly used today, including the engines of older aircraft. Non-drop-in fuels require certain modifications – for example to seals in the fuel system. They have not yet been approved.

If the energy transition succeeds in this area, who will benefit?

A world in which climate-friendly flight is a reality requires different infrastructure on the ground. There are several reasons for this. For one thing, there are so many different ways to produce non-fossil fuels that there are bound to be regional differences in solutions. At present, the oil and gas industry is concentrated in 22 countries, which supply 90 percent of all fossil feedstocks. Half of the produced amount comes from just five countries. According to estimates from the DEPA2050 study, 5000 to 7000 refineries worldwide will be required to produce the necessary quantities of SAFs. In future, this will give rise to regionally diverse production, rather than monopolies. This could result in the creation of 14 million jobs in and around production – not just in Europe, but worldwide.

At present, SAF's market share is less than one percent. How is the market set to ramp up?

Advances are already underway, triggered by two major policy decisions. In 2021, the USA launched the 'SAF Grand Challenge', a funding programme for the domestic production of biogenic SAFs. The goal is to produce more than 11 billion litres per year by 2030. For its part, the EU chose a different path and set quotas in spring 2023. Both measures have given producers planning security. It is clear that both start-ups and large corporations are now starting to invest in the development of a new industry.

An article by Anja Tröster from the DLRmagazine 175