Four hundred flight manoeuvres with ISTAR advance its digital twin

- Sensors on ISTAR measure flow fields and wing loads pushing the boundaries of what can be achieved during flight.

- Flight campaign began in February 2023 in Braunschweig.

- The data will complement and improve ISTAR’s digital twin to the point of virtual flight testing.

- Focus: Aeronautics, digitalisation

The In-flight Systems and Technology Airborne Research (ISTAR) aircraft has begun scientific operations. ISTAR flights focus on the flight-mechanical and flight-dynamic characteristics of the modified Dassault Falcon 2000LX. Novel sensors measure how the aircraft behaves during specific flight manoeuvres. The German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) will use the results to further develop ISTAR’s digital twin. This will lead to more energy-efficient aircraft designs. The digital twin becomes an exact virtual image of the aircraft in a computer.

The flight manoeuvres and ground tests bring together data from novel measurement techniques with state-of-the-art simulation tools. "The digital twin will make virtual flight tests possible in the future," explains project manager Heiko von Geyr from the DLR Institute of Aerodynamics and Flow Technology in Braunschweig. ISTAR should not be limited to testing solely within a flight simulator; instead, it should be possible for the aircraft to undergo realistic testing. The aim of the High-speed inflight validation (HighFly) project is to combine several processes: "This enables us to predict the structural deformation, the airflow and the accelerations at any point on ISTAR at any given time," explains Geyr. Until the researchers can realistically map the aircraft’s behaviour digitally, they have to compare the computational models with measurement results and develop them further. "Only then will we be able to determine whether an aircraft behaves exactly the same on the computer as it does under real conditions."

ISTAR has been taking off from the airport at DLR’s Braunschweig site for measurement flights since the end of February 2023. In Braunschweig, the aircraft was modified for scientific purposes and prepared for the project. Almost 400 manoeuvres have been flown so far at different speeds, altitudes and in different environments in a reserved airspace over Mecklenburg-Western Pomerania. In the future, researchers will be able to test new aircraft designs digitally at a relatively early stage using a digital twin. This will also enable them to assess whether changes affect the aircraft characteristics and flight behaviour. In addition to virtual flight tests, the researchers are also working towards simulation-based certification in the long term. This could accelerate time-consuming and cost-intensive approval procedures in aeronautics.

HighFly project investigates changes during flight manoeuvres

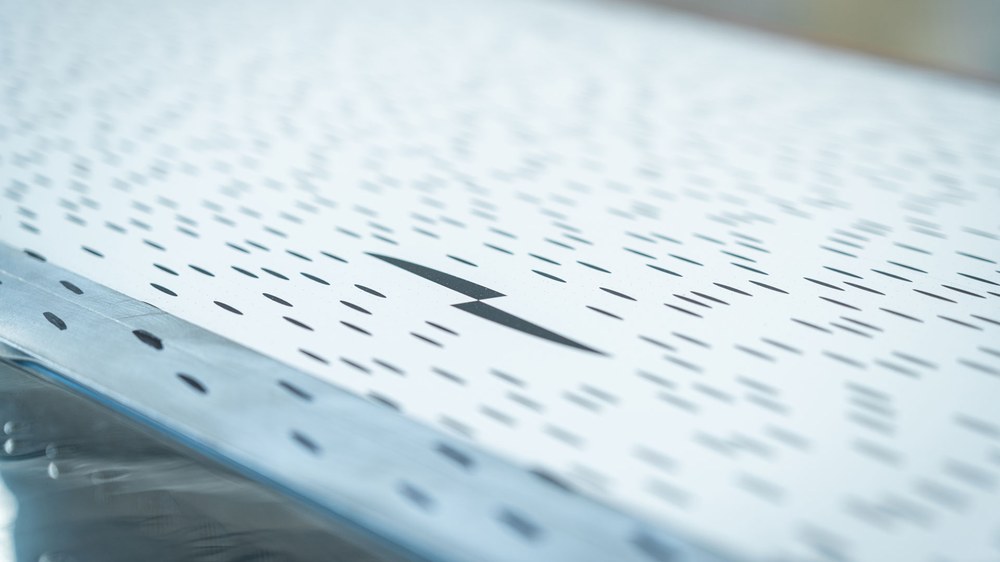

To measure how the airflow on the wings changes during different flight manoeuvres and how much the wings deform during flight, the researchers attached a dotted foil on the left wing. Up close, some of the dots are round, and some have an elongated shape. Looking through the cameras inside the fuselage pointing at the wing from a certain angle, all the dots appear the same. When the wings bend during flight, the cameras record the change in position of the dots. This is how the local deformation of the wing is determined.

Video: Deformation of the ISTAR wing, recorded by the interior camera

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

Sensors are distributed on and under the right wing. These Microelectromechanical Systems (MEMS) sensors measure the pressure and temperature distribution with high accuracy and high frequency during the flight tests. “The MEMS system is a completely new development within the project and is being used here for the first time in the transonic speed range under real flight conditions,” says Geyr. In the transonic range, the aircraft flies slower than the speed of sound, but the airflow around the aerofoil still reaches supersonic speed in places. This results in a very complex flow with compression shocks, which must be reliably detected by the MEMS sensors.

In addition, three MEMS sensor surfaces are installed near the flight deck. They measure pressure fluctuations in the thin boundary layers, which are created here by the shape of the aircraft. The DLR Institute of Aerodynamics and Flow Technology in Göttingen developed the MEMS sensor surfaces.

Valuable database

The test pilots fly precisely defined manoeuvres with ISTAR at 11,000, 25,000, 35,000 and 45,000 feet. These correspond to altitudes of 3350, 7620, 10,670 and 13,720 metres. The computers located in the cabin store all the readings. The researchers later compare the treasure trove of data with the results of the numerical simulation. Supercomputers, such as DLR’s CARO and CARA clusters, are essential for this. "With our measurements, we cover the entire transonic flight range, pushing the boundaries of what can be achieved during flight. The combination of measurement techniques makes this database unique and extremely valuable," explains Geyr.

Video: Flight deck view during a flight manoeuvre with ISTAR

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

Researchers from the DLR Institute of Flight Systems have also conducted Parameter Identification (PID) flights as part of the HighFly project. This results in a flight dynamic simulation model of ISTAR. This can then be used in a flight simulator such as the Air Vehicle Simulator (AVES). “In this way, we can first test newly developed flight control and assistance systems using the simulator before we test them during flight,” says Christian Raab from the DLR Institute of Flight Systems.

Ground tests for the digital twin

On the ground, the researchers from the DLR Institute of Aeroelasticity conducted a Ground Vibration Test (GVT) and Taxi Vibration Tests (TVT) in the summer of 2021. "The results are relevant far beyond the HighFly project; every modification of ISTAR needs an aeroelastic analysis to demonstrate the operational safety of the modification," explains Marc Böswald from the DLR Institute of Aeroelasticity. Aircraft do not have a completely rigid structure. To fly safely, elasticity must therefore be taken into account.

During the GVT, ISTAR was supported on jacks and subjected to vibrations. More than 200 additional sensors measured ISTAR’s reactions, and these were used to create a model. In the TVT, ISTAR was pulled along the runway. Uneven ground causes vibrations via the landing gear. During the current flights, the researchers also monitored the aeroelastic properties of ISTAR using newly developed methods. In future, these tests could also be carried out using the digital twin.

The DLR Institute of Aerodynamics and Flow Technology also measured the airflow to the engines with Particle Image Velocimetry (PIV) for various thrust settings. The engine inflow influences the aerodynamics of ISTAR. The data obtained has also been made available for the digital twin.

ISTAR

The In-flight Systems and Technology Airborne Research (ISTAR) aircraft has been part of DLR’s research fleet since 2019. The upgrading of the aircraft will take place in several stages. By the mid-2020s, it will be fully operational as an airborne simulator and will advance the digitalisation of aeronautics. Once fully modified, ISTAR will be able to test the properties of new aircraft designs under real or virtual conditions. The digital twin will accompany ISTAR throughout its entire service life. The research aircraft is based at DLR’s Flight Experiments Facility in Braunschweig, where it is part of the largest civilian research fleet in Europe.