EDEN ISS

Project EDEN ISS

Sustained human presence in space requires the development of new technologies and processes to maintain environmental control, to manage wastes, to provide water, oxygen, food and to keep astronauts healthy and psychologically fit. Bio-regenerative life support systems (BLSS), in particular the cultivation of higher plants, are advantageous from this regard due to their ability to be employed for food production, carbon dioxide reduction, oxygen production, water recycling and waste management. Furthermore, fresh crops are not only beneficial for human physiological health, but also have a positive impact on crew psychological well-being.

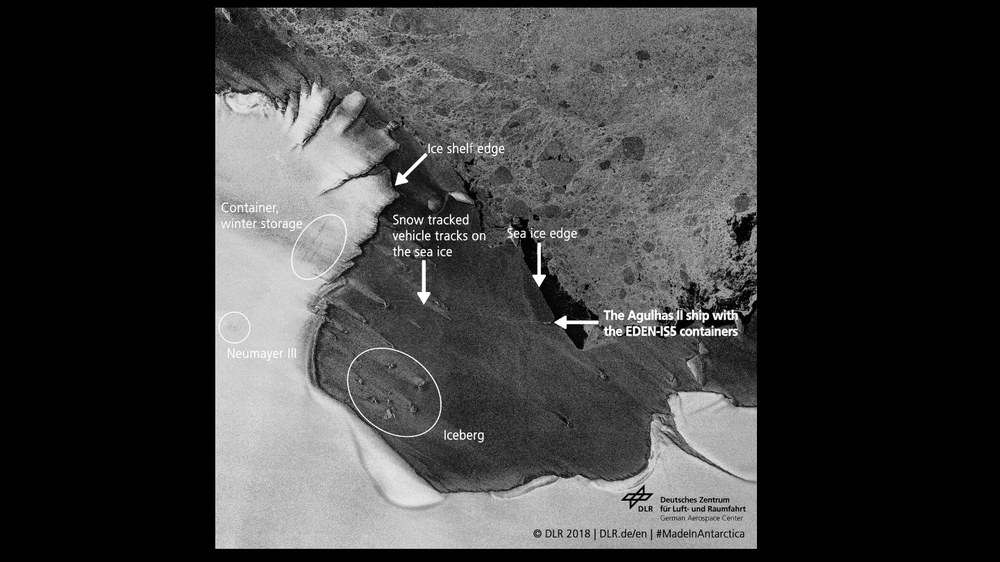

The EDEN ISS project was a 4.5 M€ European Union Horizon 2020 project (reference number: 636501) supported via the COMPET-07-2014 - Space Exploration – Life Support Subprogramme. It had its official kick-off in March of 2015 and ended in April 2019 after the completion of a year-long Antarctic deployment phase in which the EDEN ISS greenhouse system was installed and operated in the vicinity of the Neumayer Station III. The EDEN ISS consortium was comprised of leading European experts in the domain of human spaceflight and controlled environment agriculture (CEA) and partners from Canada and the USA. The EDEN ISS scientific advisory board consisted of the top scientists in the field of space greenhouses from Russia, USA, Japan, Italy and Germany.

Objectives

Due to the necessity of validating key technologies for space greenhouses under mission relevant conditions and with representative mass flows, the EDEN ISS consortium defined six objectives:

- Manufacturing a space analogue Mobile Test Facility (MTF)

- Integration and test of an International Standard Payload Rack (ISPR) plant cultivation system for future tests on-board ISS and a Future Exploration Greenhouse (FEG) for planetary habitats

- Adaptation, integration, fine-tuning and demonstration of key technologies

- Development and demonstration of operational techniques and processes for higher plant cultivation to achieve safe and high-quality food

- Study of microbial behaviour and countermeasures within plant cultivation chambers

- Actively advancing knowledge related to human spaceflight and transformation of research results into terrestrial applications

Design Overview

The EDEN ISS greenhouse, or Mobile Test Facility, has been designed to provide fresh produce for wintering crews at the Neumayer Station III in the Antarctic while in parallel advancing the spaceflight readiness of a number of key plant growth technologies. The greenhouse also serves as a tool to develop operational procedures and select science aims associated with remote plant production. The greenhouse consists of two 20 foot high cube containers, which have been placed on top of an external platform located approximately 400 m south of Neumayer Station III.

The actual system can be subdivided into three distinct sections:

- Cold porch/airlock: a small room providing storage and a small air buffer to limit the entry of cold air when the main access door of the facility is utilized

- Service Section (SES): houses the primary control, air management, thermal control, nutrient delivery systems of the MTF as well as the full rack ISPR plant growth demonstrator

- Future Exploration Greenhouse: the main plant growth area of the MTF, including multilevel plant growth racks operating in a precisely controlled environment

Project Status

During the first wintering period in 2018 with one DLR-person on site, the EDEN ISS consortium tested key CEA technologies using an international standard payload rack (ISPR) crop cultivation system for potential testing on board the International Space Station (ISS). In addition, the FEG was used to investigate technologies for Bio-regenerative Life Support Systems (BLSS) for planetary surfaces (Moon, Mars). In addition to technology development and validation, procedures for food safety and plant handling were developed and tested in Antarctica. These represent integral aspects of the interaction between the crew and the systems in closed environments. In 2018, 268 kg of edible biomass were produced in nine months.

In January and February 2019, four DLR project members, together with two partners from the University of Florida, travelled again to Antarctica to work on the greenhouse system and to carry out repairs and improvements to the system. After this repair- and maintenance mission, the facility was put into a hibernation-mode with only minimal functionality. This was done to allow the EDEN group to test the procedures associated with a remote automated start of the plant and to observe possible adverse effects of such a reduced operating mode. This information is useful for future greenhouses in space, which may be idle for some time until the astronauts' planned arrival. In May 2019, the second phase of operation was initiated, with the winter crew of Neumayer Station III carrying out the plant cultivation work on site. In the following months, until the end of November 2019, the mobile test facility produced around 106 kg of edible biomass, which was available to the winter crew.

Although the project officially ended in April 2019, the German Aerospace Center (DLR) and the Alfred-Wegener Institute agreed to continue operation of the EDEN ISS facility at the Neumayer Station III through 2020 and beyond.

The third operating phase of the greenhouse container is currently underway in cooperation with the winter crew of Neumayer Station III in Antarctica. First results are expected by the end of 2020.

The EDEN ISS greenhouse will be operated in Antarctica in order to gain important insights into the operation of a CEA greenhouse. Experiments for 2020-2023 are already being planned in collaboration with NASA including their wintering personal in situ and other partners. In addition, key aspects of the facility are to be developed further. This includes continued developments of the Nutrient Delivery System, improvements in energy efficiency and the implementation of robotic systems as well as the characterization of the microbiological fauna in the greenhouse (DLR-ME). The findings from these analogue missions will then be incorporated into other projects.

Downloads

- Portfolio and Strategy (8.2 MB)

- Highlights 2014 (5.4 MB)

- Highlights 2015 (2.3 MB)

- Highlights 2016 (6.7 MB)

- Informationsletter (DE) (832.8 KB)

- Information Letter (EN) (717.4 KB)

- Highlights 2017 (14.4 MB)

- Project Partners (305.6 KB)

- Press & Publications (273.5 KB)

- Frequently Asked Questions (FAQ) (122.8 KB)

- Project Flyer (1.2 MB)

- Highlights 2018 (3.3 MB)

- DLR_BLSS Roadmap (4.1 MB)

- White Paper Agrospace2016 (444.6 KB)

- Highlights 2020 (7.0 MB)

- Highlights 2021 (4.3 MB)

- Highlights 2022 (24.2 MB)

Links

- Zur EDEN-ISS Webseite

- Inforadio: Garten EDEN in der Antarktis

- ZDF Morgenmagazin - moma:future: Gurken im Weltall

- Science Clips: Tomaten im Weltall

- Pressekonferenz zu EDEN ISS (13.9.2018)

- EDEN ISS — Greenhouse for ISS, moon and Mars

- EDEN ISS greenhouse in Antarctica for space

- EDEN ISS - Ground Demonstration of Plant Cultivation Technologies and Operation in Space

- EDEN:ISS Antarktis für die Nahrungsmittelversorgung der Zukunft

- EDEN ISS auf Facebook