Robotic SEAM - Robotic Screw Extrusion Additive Manufacturing

At the heart of the cell are four compact single-screw extruders, which enable additive manufacturing based on standard granulates and are guided by industrial robots. Here, the spatial degrees of freedom of the positioning system are combined with the flexibility of the extrusion system in terms of available and processable materials, making it possible to serve product areas not previously covered by additive manufacturing. In particular, the high production speed, large component dimensions and the processing of highly filled materials, e.g. for structural components, should be mentioned.

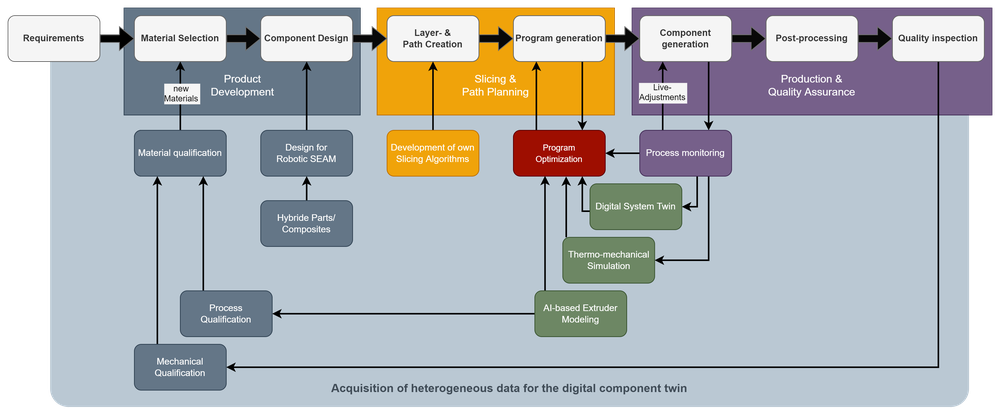

In addition to purely additive manufacturing, hybrid manufacturing, i.e. the combination of different process types and materials in one component, is also being investigated in the project. For example, existing semi-finished products or components can be printed with additive structures in order to reinforce or otherwise functionalise them. The entire process chain, from component design, qualification of materials and material combinations, intelligent planning and generation of robot paths and the production data set through to monitoring the production process and integrated quality assurance, is being analysed.

A particular focus is on digital processes that make the digital process chain faster, more robust and easier to operate, thereby making production more reliable and productive. The processes include the development of AI models for predicting extrusion behaviour and accelerated material qualification, the development of a software tool for expanding the scope of application of additive manufacturing processes, the development of specialised slicing algorithms, particularly for the hybrid manufacturing approach, the development and use of a digital plant twin for trajectory optimisation and a comprehensive in-line data acquisition system for generating digital component twins.

Additive manufacturing for industrial applications in vehicles

Additive manufacturing processes (AM) can offer the opportunity to meet future mobility requirements and the vehicles needed for this. In particular, the prospect of (partially) autonomous driving opens up new usage concepts and therefore demands for a flexible structure and a customisable interior. In addition, model and development cycles are becoming ever shorter. These developments pose a major challenge to production and, in particular, to its flexibility.

As AM processes generally do not require a component-specific mould, they can in principle produce geometrically different components one after the other without additional set-up times. The flexibility is therefore given in this respect, but most processes lack productivity and material selection. The Robotic SEAM process principle addresses these limitations and can be used in new areas that were previously served by conventional processes such as injection moulding. Hybrid additive manufacturing on existing structures for functionalisation and customisation is a particularly promising approach here.

Additive manufacturing for industrial applications in vehicles

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

The aim of this project is to identify the obstacles to this still young process and to develop appropriate solutions that enable and support its wider use. This will only work if the entire process chain, especially the digital one, is taken into account.