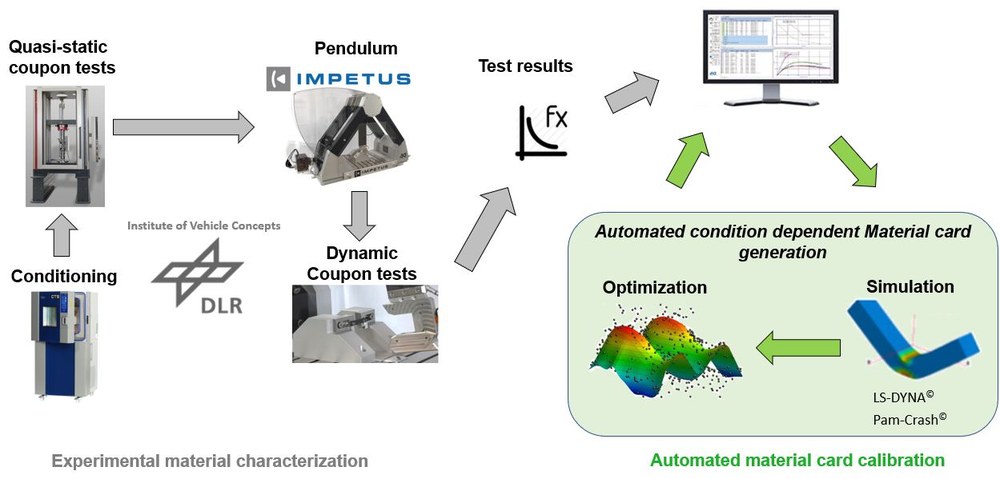

In this research field a material laboratory for automated material card development was setup, linking the required material characterizations tests with numerical optimization strategies for the fast and efficient development of validated material cards for crash simulations

Laboratory for automated material card development

Material card development for crash application is a very challenging task due to the complexity of modelling the high non-linear material behavior of materials exposed to crash loads. For an automated material model development process, a material laboratory was built up combining a closed loop between material characterization tests and an automated material card optimization procedure. The material characterization can consist of quasi-static and dynamic coupon tests investigating conditioned material specimens. Thus, temperature, moisture and strain rate depended material descriptions can be derived.

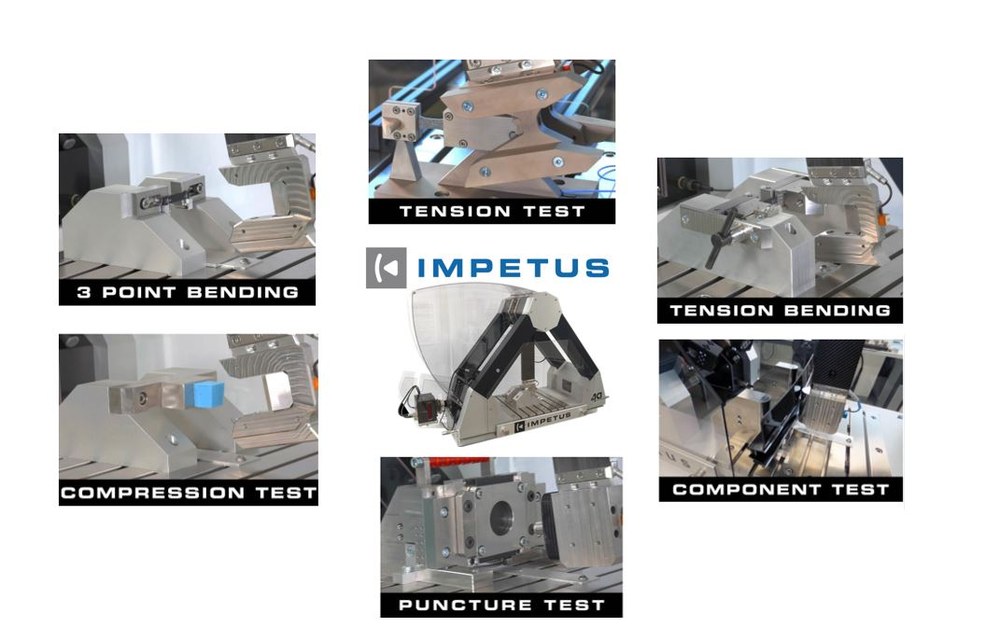

For dynamic testing the IMPETUS® pendulum is used for rate depended specimen loadings. The pendulum is a testing machine, which enables the mechanical characterization of dynamically loaded material specimens or small components under defined uniaxial or biaxial stress states. The experimental data can be directly linked to the optimization environment VALIMAT® which generates an interface between the test data, the explicit simulations environment and a meta-model-based optimizer. Due to the combination of predefined coupon tests and defined interfaces to explicit solvers, numerical material descriptions can be automated calibrated and directly validated by this applied methodology.

Overview on the automated material card development process

- Various test setups available: bending-, tension bending, dynamic tensile-, puncture- and compression test

- Applicable for plastics, composites, foams & aluminum

- Strain rate depended measurements with customizable support distance and clamping conditions

- Impact speeds between 0.5 up to 4.4 m/s and a maximum impact mass of 5.5 kg [impact energies up to 50 J]

- Measurements with digital image correlation [DIC] possible

- Application for user-defined material cards and user-defined specimens possible

- Automated material calibration for different FE-solvers (LS-DYNA©, Pam-Crash©) available