The aim of this project is to bridge the gap between the micro-structural design and the mechanical properties by coupling experimental and simulative data, and subsequently to significantly reduce the time and effort required for characterisation when transferring the product to the application.

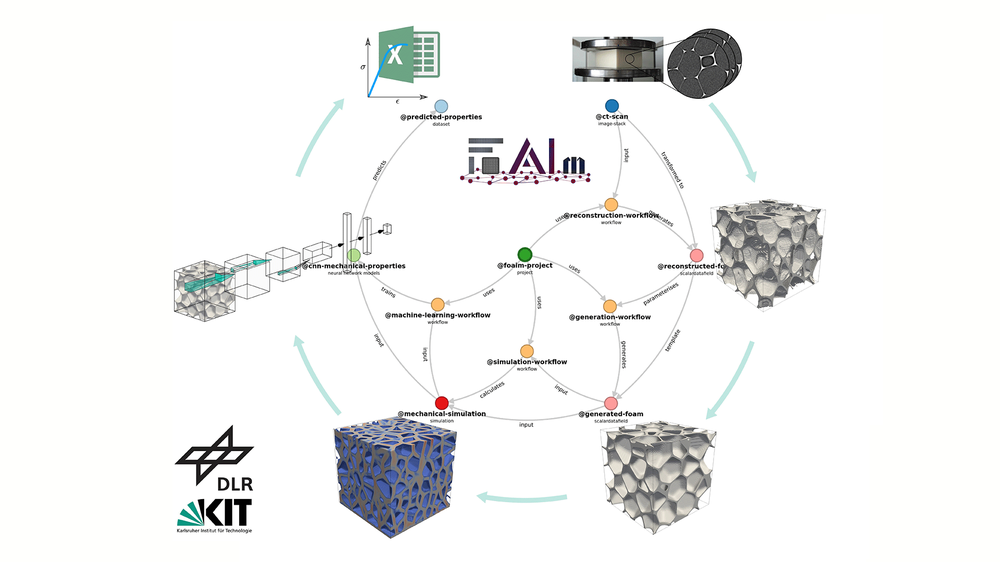

In FoAIm, a general concept for such a digital workflow is developed and demonstrated on structural foams. Experimental tests and synthetically generated microstructures provide the basis for the data. Explainable AI approaches are integrated into the ML framework so as to be able to predict the mechanical properties based on the microstructure as well as to derive optimised microstructures for the loading case in question. The transfer to sandwich structures under loads in which the failure of the foam core dominates is to be evaluated. In order to be able to use the results beyond the project framework, they will be handled according to the FAIR data principles and gateways will be set up to link the results with other Helmholtz activities (e.g. KNMFi) as well as with projects on a national level (e.g. NFDI4Ing).