In virtual design, simulation and M 1:5 experiments, the concept of a new type of structurally optimized single-wheel undercarriage with mechatronic track guidance and direct drive close to the wheels has proven to be a promising approach.

As a next development step, a functional M 1:1 prototype of the NGT bogie has now been built and will now be made available as the NGT bogie research infrastructure (FuN) for DLR internal and external research activities From 2024, FuN will then initially be operated for three years in two annual measurement campaigns on external rolling test benches. In addition, further testing in a rail vehicle on test and inspection facilities is planned.

Project objectives

- Validation and demonstration of the three basic innovations for rail vehicle running gear proposed in the NGT project mechatronic track guidance

- Lightweight construction and wheel-oriented direct drive

- Enhancement of NGT project results for technology readiness level (TRL) 6

NGT bogie technologies

Mechatronic track guidance

Conventional track guidance in today's high-speed bogie is based on the passive stability properties of wheelsets, in which the two profiled wheels are connected to a shaft and their speeds are thus coupled.

However, the active control of the two individually driven wheels implemented in the NGT running gear allows the position of the wheel pair in the track channel to be freely determined, its alignment in the track curve to be radially adjusted, track position disturbances to be counteracted and new mechatronic functions such as wear profile control to be implemented. As the wheelset shaft is no longer required for this mechatronic track guidance system, a level passage without steps is also possible on the lower level in double-decker coaches.

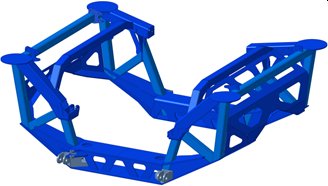

Lightweight construction

The consistent lightweight construction, methodically supported by computer-aided structural optimization, allows the realization of a traction bogie at the weight level of a conventional bogie. This increases the payload capacity while the wheel loads remain the same or, to put it the other way round, reduces the wheel loads while the payload remains the same. Raw materials and materials are saved in production, less energy is required for acceleration and braking of the dead weight during operation, and life cycle costs are reduced.

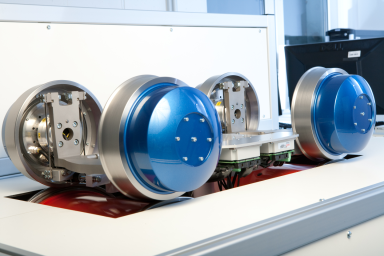

Direct drive close to the wheel

Permanently excited synchronous motors with high torque density and efficiency are used as drives, so that the lightweight construction advantages described above also have an impact on life cycle costs. The motors are rubber-sprung and mounted on the wheel carrier so that they are decoupled from high-frequency track disturbances and the unsprung masses on the track are as small as possible. Spring travel-compensating but torsionally rigid lug couplings connect the motors to the associated wheels without gearing.

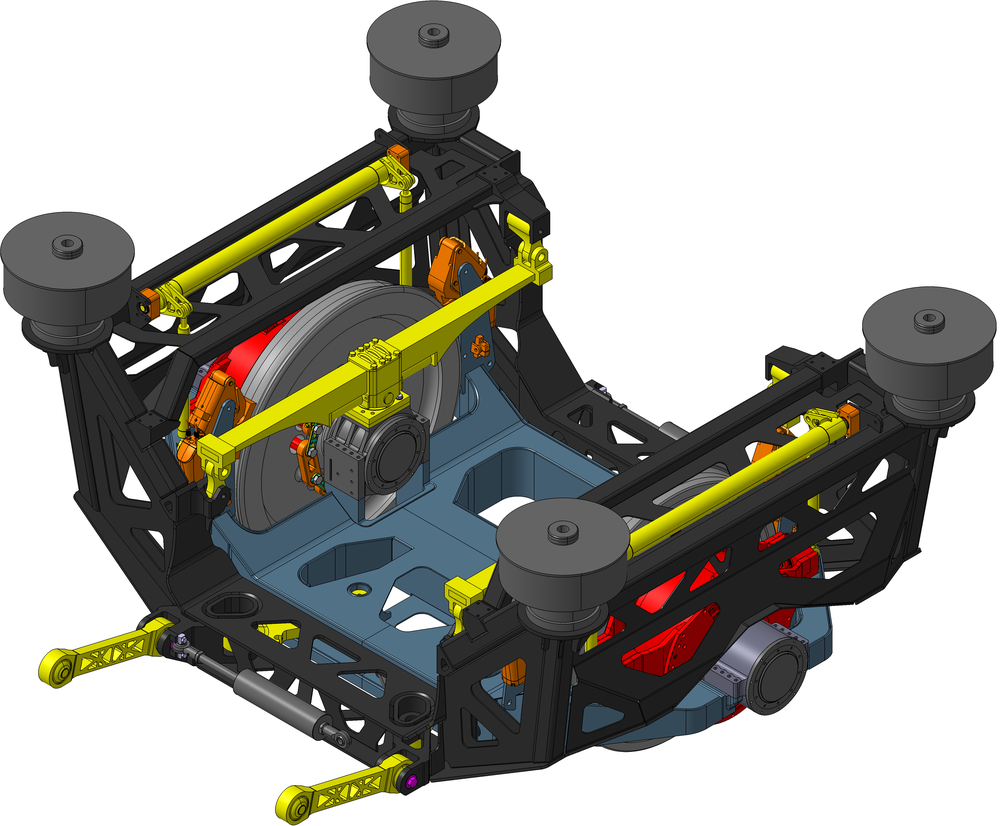

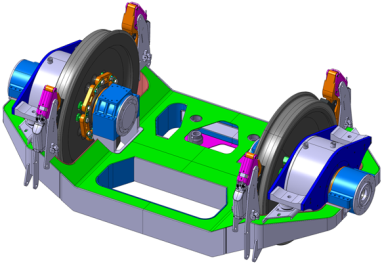

CAD design of the NGT bogie in the integration test stand

At the end of the current construction phase of the NGT-FuN project the M1:1 prototype of the NGT bogie will be available in an assembly and integration test bench. This setup, bogie in the integration test bench, enables simple, qualitative functional testing of the sensors, actuators and control and automation technology.

In addition to these qualitative experiments with a greatly reduced performance exception, the setup is suitable for demonstrating the running gear principle to visitors in the laboratory or on an exhibition stand, e.g. at Innotrans 2022.

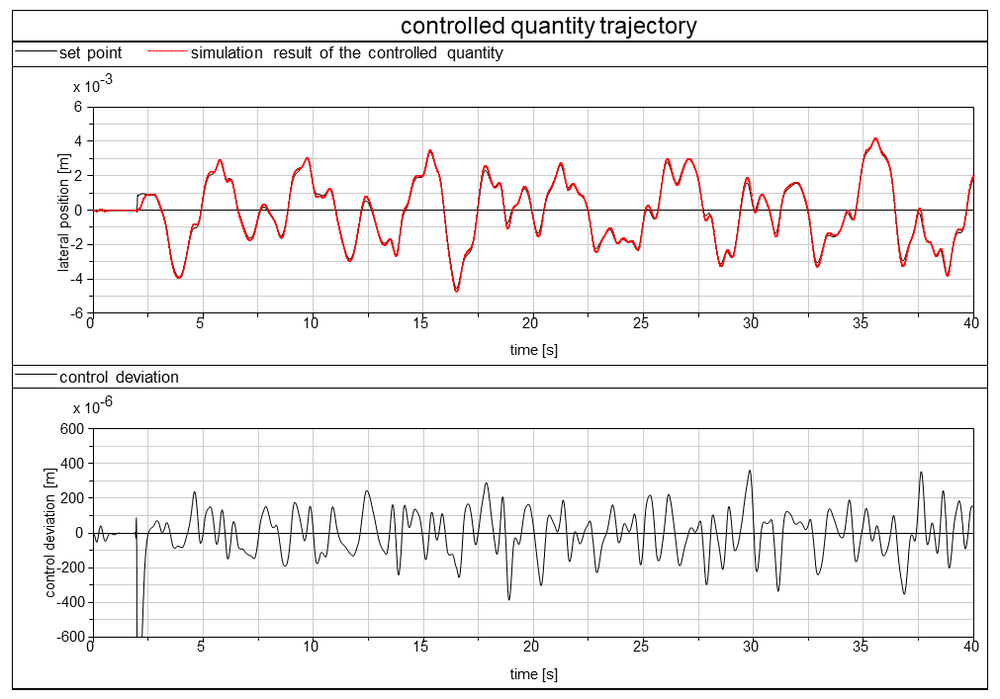

The design of the integration test stand is currently being tested virtually using multi-body simulation of the 4 different application scenarios:

- Scenario 1: straight running of the running gear, positioned in the center of the track channel

- Scenario 2: straight running of the bogie with specified lateral position in the track channel

- Scenario 3: Artificial, control-imposed wave run of the running gear with controllable frequency and travel speed

- Scenario 4: the running gear follows a predefined transient trajectory that is modeled on a stochastic track position disturbance