A battery-electric bus from Cobus used for passenger transport on the apron of Stuttgart Airport is being used as a reference vehicle. Stuttgarter Flughafen GmbH and Konvekta AG, a renowned supplier of air conditioning systems for bus applications, supported the project as associated partners.

Project goals

- Technological development of high-performance thermal storage systems for use in battery-electric buses

- Development of modular storage concepts for use in battery-electric buses

- Development of a methodology for designing high-performance thermal storage systems for use in battery-electric buses

- Investigation of a prototype setup of a high-performance thermal energy storage system in a laboratory environment

- Investigation of the potential of high-performance thermal storage systems for use in battery-electric buses

Future vehicle concepts

Road vehicles of the future will have partially or fully electrified drive concepts. Compared to conventionally powered vehicles, comparatively little waste heat will be available for air conditioning and temperature control purposes. This lack of waste heat, combined with increasing demands on efficiency and comfort, places great demands on future thermal management systems. This is particularly evident in the thermal management of battery electric vehicles, especially buses, on cold winter days. Standard electric heating elements utilise electrical energy from the traction battery to convert it into heat. The energy used for heating is lost to the drive, resulting in a reduction in the vehicle's range of up to 60 %.

Outstanding thermal performance

This is precisely where heat storage systems come in: the provision of thermal energy through comparatively small, lightweight, powerful and cost-effective thermal storage systems. DLR's MonoTherm® storage system utilises the sensitive temperature change and the energy stored in the phase change of the storage material. When the storage material is loaded, it heats up and liquefies; when it is unloaded, it cools down and solidifies. Metallic phase change material (mPCM) with operating temperatures of 100 °C to 600 °C is used. Due to their thermophysical properties, such storage materials, which are new in this application, have excellent thermal performance and high specific storage capacity. One potentially suitable mPCM is the eutectic alloy AlSi12, for example, whose technical use is already known from applications in the foundry sector or as a piston material for combustion engines.

Operating strategy and potential

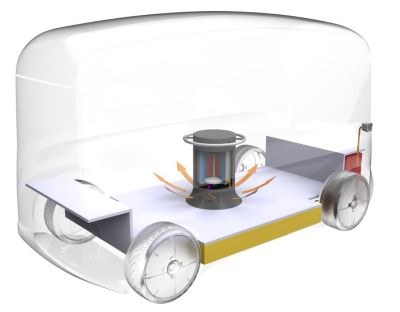

When used in an electric bus, the MonoTherm® heat storage system can form the central component for heating the interior, as shown in the picture for a minibus. A MonoTherm® storage system could also be used profitably in combination with a heat pump as a supplementary heating system for low ambient temperatures or for smoothing power peaks. The range of electric buses is increased by charging the storage tank as required while the traction battery is being charged at the charging station. The additional option of recuperating braking energy can reduce the load on the battery and thus increase the efficiency of the vehicles. With storage densities of up to 250 Wh/kg and 500 Wh/l, significantly more compact, lighter and cheaper storage systems already seem possible compared to batteries at the current stage of development. The MonoTherm® storage system is also characterised by the fact that it does not require rare raw materials and is almost completely recyclable.

The central boundary condition for the development of a THS is the heating power requirement of the corresponding reference vehicle. As no data on the heating power requirement of the battery buses used at Stuttgart Airport is available to date, a suitable measuring system was installed in the FB71 airport bus between January 2019 and March 2019. Temperature sensors on the coolant lines were used to determine the operating status of the installed electric heater. As this is operated in ON/OFF mode, the heating power supplied can be determined by detecting corresponding temperature rises in the coolant flow.

In addition to the measurements to determine the heating power, the interior temperatures in the driver's cab and passenger compartment were also detected and a position measurement was carried out via GPS. This can be used to carry out further analyses on the operation of the buses if required.

The results for measuring the heating power requirement are shown in the diagram below. Each of the points plotted in the diagram corresponds to the average heating power supplied within one hour above the ambient temperature. The ambient temperatures originate from the measurement of the air temperature by the German Weather Service at Stuttgart Airport. The large dispersion of the heating output above the ambient temperature can be clearly seen. This is due to the variance of a large number of effects that influence the required heating output. These include, for example, the duration of door opening, solar radiation, the desired temperature in the driver's cab, wind speeds, the number of passengers transported, etc.

Position paper

To draw attention to the challenges of heating battery-electric buses, the DLR has produced a position paper together with various partners. Konvekta AG, ZAE Bayern and the Hanover transport company ÜSTRA are involved. The position paper can be downloaded from the download area.

Associated project partners

- Konvekta AG

- Stuttgart Airport GmbH