Future road vehicles will have partially or fully electrified drive concepts. In comparison with conventionally powered vehicles, there is comparatively little waste heat available for air conditioning and temperature regulation purposes. This lack of waste heat with simultaneously increasing demands on efficiency and comfort, places great demands on future thermal management systems. This is particularly evident in the thermal management of fully electrified vehicles on cold winter days. Standard PTC heaters use electrical energy from the traction battery and convert it into heat. In this process, the drive system loses this energy, which results in a range reduction of the vehicle by up to 50 per cent.

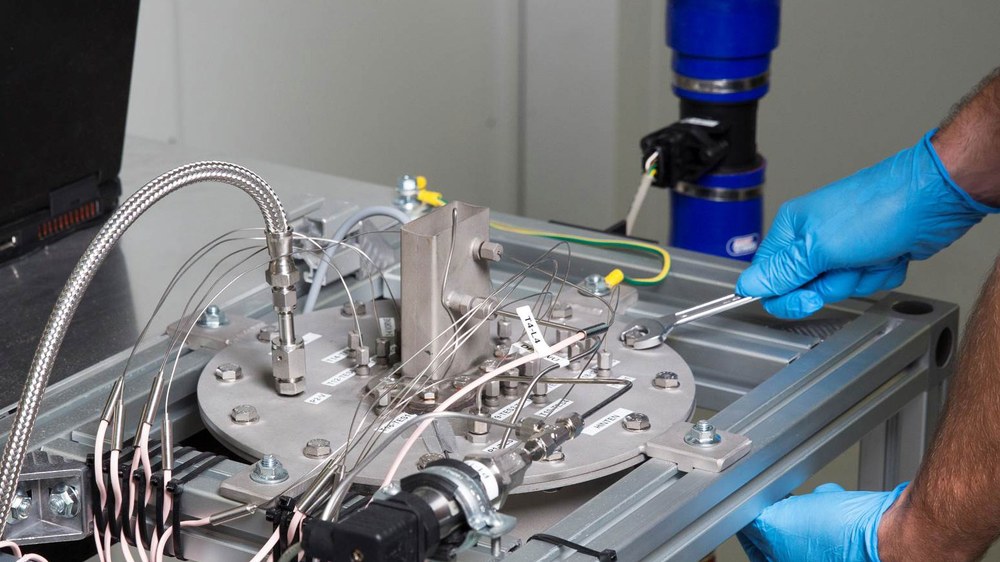

This challenge is targeted by heat storage systems, that provide thermal energy through comparatively small, lightweight high-performance and cost-effective systems. The thermal storage system, developed by DLR, utilises the sensitive change in temperature and the phase change of the storage material to store energy. During charging, the mPCM is heating and melting while during discharging, it is cooling and solidifying. Intelligent need-based charging can be carried out in parallel when charging the traction battery at the charging station. The heat released during the subsequent discharging can be made available to the interior of the car.

Metals are used as storage material. In comparison to other phase change materials, metals stand out due to their high heat conductivities. As a result, high charging and discharging performance is possible, resulting in short charging times and high heating capacity. High energy densities and specific amounts of energy also promote a small and lightweight design.

The competencies at DLR encompass a holistic development, starting with the storage material right through to the vehicle-friendly overall system. In cooperation with other DLR institutes, the Institute of Vehicle Concepts in Stuttgart provides a broad basis and functions as a strong development partner for industry.