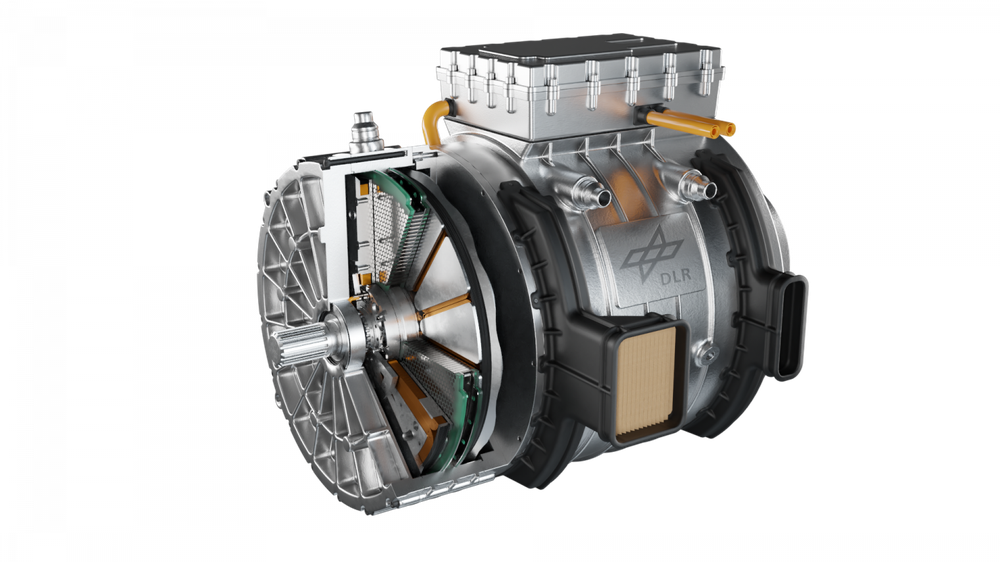

With a mileage of 69 billion kilometres, heavy commercial vehicles emit 2253 tonnes of brake dust with an emission factor of 32.7 mg/km. This corresponds to the total mass of 55 lorries with a total mass of 40 tonnes. For this reason, a wear-free high-performance eddy current brake was developed at the DLR Institute of Vehicle Concepts in Stuttgart. Work is currently underway on integration concepts for specific vehicles. The aim is still to increase power density and reduce wear in order to minimise the use of mechanical brakes, which are subject to emissions and wear.

In electric drive concepts, the eddy current brake supports the traction machine during braking processes in which the drive system cannot supply the required braking torque and recuperation is not sufficient.

In the application area of heavy commercial vehicles, a reduction of >95% in particulate emissions in the braking system can be achieved. The remaining particulate emissions are due to the mechanical brake. This is still required to brake to a standstill.

Thanks to its modular design, the high-performance eddy current brake can be combined with various electric traction machines and its performance can be scaled:

- Wear-free

- Maintenance-free

- Free of fine dust

Project goals

- Reduction of brake dust emissions

- Development of an eddy current brake with a power density of 9 kW/kg

- Demonstration and measurement on the test bench