ATEK Flight Experiment - Propulsion Technologies and Components of Launcher Stages

The flight experiment ATEK (Propulsion Technologies and Components of Launcher Stages) of the German Aerospace Center (DLR e.V.) consists of Health-Monitoring-Systems for critical launcher components and a hybrid payload structure. Also a MAPHEUS-8 payload consisting of several biological and material science experiments belongs to the ATEK flight experiment.

The ATEK project is part of one of the research areas ‚Space Transportation Systems‘ of DLR’s space research and technology program. ATEK’s main objective is the development and flight qualification of structures, measurement techniques and analysis tools, which are used for thermo-mechanical evaluation of launchers. Flight data, in combination with ground experiment results, are the key element of the validation of physical models, numerical simulation and system analysis tools, which are used to evaluate and to design future space transportation systems.

The ATEK flight experiment was successfully launched on 13th July 2019 at 4:21 AM (CEST) from the launch site Esrange in Kiruna Sweden and reached an apogee of approx. 240 km. Approx. 13 seconds after take-off, the first stage S31 of the VSB30 launcher was burned-out and separated. The second stage S30 was ignited immediately afterwards and provided thrust for 29 seconds. Three seconds after a de-spin maneuver by a Yo-Yo system the S30 was separated from the payload. During this first 60 seconds an aerodynamically stable flight could be enabled. The second stage and the payload continued the descent without any thrust and landed approx.. 500 seconds after the take-off at a distance of approx. 67 km from the launch site. The payload was decelerated in the late subsonic flight phase using a parachute to avoid a hard impact on ground after a 800 seconds flight time. The stage S30 experienced a hard ground impact after a planned uncontrolled descent flight.

The Health Monitoring System allowed the measurement of aerothermal and mechanical loads on the hybrid payload structure, motor adapter, motor case, tail can and fins along the complete flight. Part of the data was transmitted during flight to ground via telemetry at a low sampling rate of several Hertz. In addition, several impact-resistant data acquisition units could acquire the data at a high sampling rate of several Kilohertz and stored it onboard. The hybrid payload structure and health monitoring data acquisition units were recovered after the flight and showed complete functionality. These results demonstrate flight qualification of the following payloads and technologies:

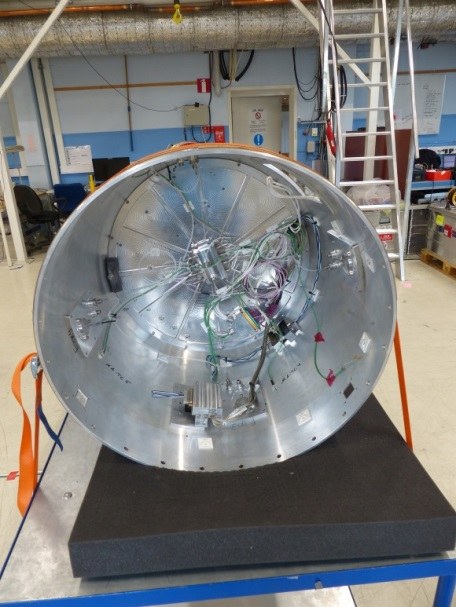

Flush Air Data Sensing (FADS) and Health Monitoring for the Motor Adapter

A Flush Air Data Sensing system, consisting of five high resolution pressure transducers, allows the determination of flight angles along the flight trajectory, including the impact of wind. A recently developed in-house heat flux sensor measures the total heat flux evolution at selected positions. This data in combination with several thermocouples, which record the structure temperature, are used for the validation of aerothermal design tools. The data acquisition is performed using a modular and crash resistant system.

Health Monitoring System for Motor Case, Tailcan and Fins

The tailcan Health Monitoring package detects thermo-structural properties of the motor case, nozzle, fins and the tailcan with different types of instrumentation. The motor case temperature is measured with fiber Bragg gratings. One fin is instrumented with strain gauges, thermocouples and pressure sensors. Fin surface temperature distributions are monitored using a compact infrared camera installed in the tailcan. In addition, an infrared camera is placed inside the tailcan to monitor the external wall temperature of the nozzle throat region. Radiometers with different spectral range are measuring the plume radiation, which is used to determine the plume temperature.

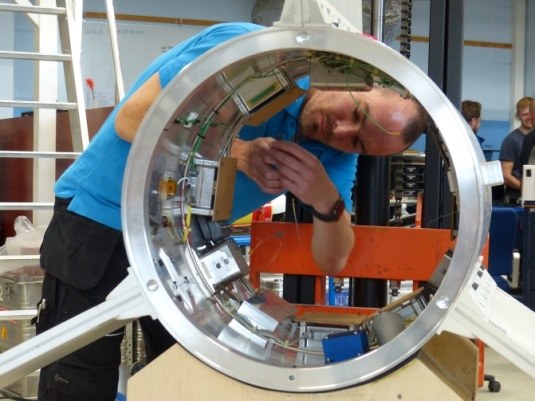

Hybrid Payload Module

The Institute of Structures and Design developed a new payload structure using ‘Automated Fiber Placement’ (AFP) technique to manufacture a sounding rocket primary structure comprised of carbon fiber-reinforced thermoplastic (CF-PEEK). This single-step (in-situ) manufacturing method allows eliminating expensive and time-consuming vacuum-bagging processes. Operational loads are transferred to the structure via HI-LOK screw rivets. This module, which passed all qualification tests, successfully, represents the first generation of in-situ AFP-produced primary structures for real flight applications. The payload is equipped with thermocouples and fiber Bragg grating (FBG) and strain gauges of the department AS-HYP. The inner wall temperature distribution is measured at a 1 kHz sampling rate using optical fibers integrated along the structure surface.

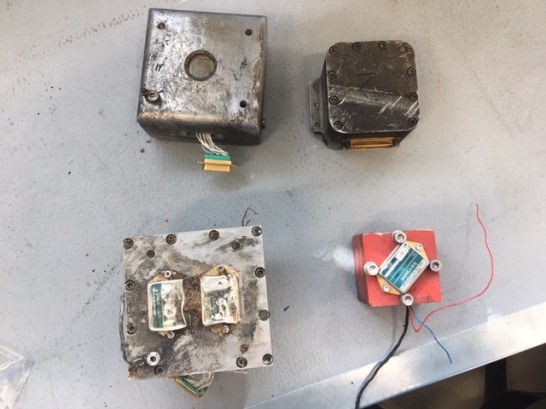

Impact-Resistant Data Acquisition System

The payload data acquisition system for Health Monitoring is modularly designed. This feature allows short harnesses for widely distributed sensors and simplifies the integration of the components in particular for spacecrafts with limited volume available. Different types of sensors can be connected to the acquisition unit. Each measurement channel can be configured individually to use the complete dynamic range of the sensors. The acquired data can be transmitted to the ground station via telemetry or stored in the impact-resistant storage unit. Due to its own battery the data acquisition is autonomous. Using additional modules further payloads like infrared cameras, FOS units, etc. can be connected.