Bump detection for production lines

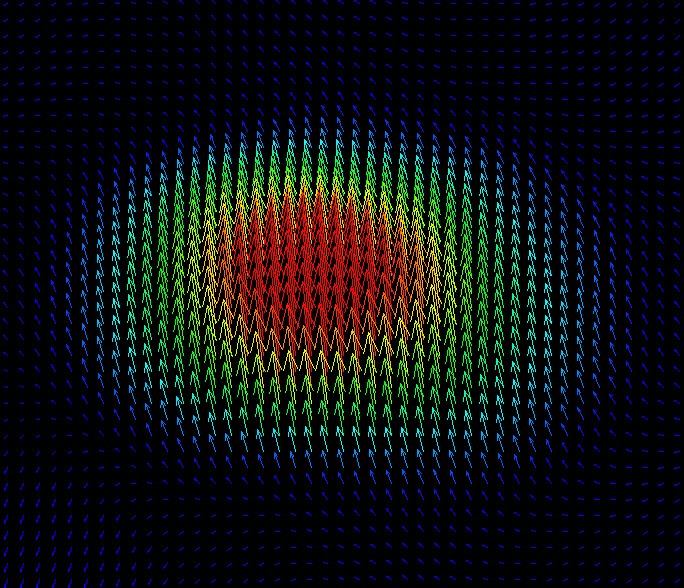

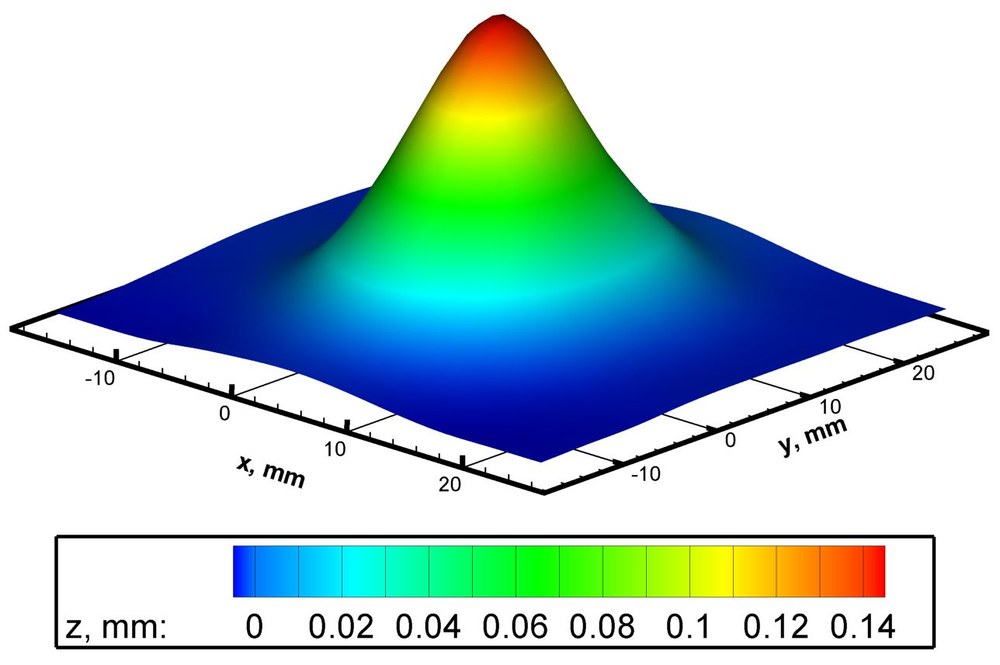

For quality control of metal sheet components, a very common measurement task is to find bumps or defects with a diameter in the millimeter range and a depth in the micrometer range. For demonstration purposes we applied an artificial bump on a car door surface, which was afterwards measured using the PROPAC technique. The spatial dimension of the bump was about 2 x 2 square centimeters and it was about 140 micrometers deep. For the measurement, we used an off-the-shelf LCD projector with 800 x 600 pixels as well as a 1.4 mega pixel CCD camera with 12 bit resolution and active cooling. The recorded image data was processed using our in-house developed cross-correlation software. On the right side, you can see the results of the local cross-correlation algorithm and the final deformation, both color-coded. In this case, a spatial resolution on the surface of about 0.5 mm and an accuracy of the deformation of better than 1 µm was achieved.

The presented measurement principle based on cross-correlation of random dot patterns is very modular, since different quantities (deformation, slope, and velocity) can be measured on different surface types. In addition, the PROPAC technique is considerably fast, which allows us to handle moving objects. Future work will be the investigation of evaluation algorithms which allow an improved spatial resolution.

Other possible applications in addition to real-time quality control are vibration analysis of oscillating objects, local deformation or velocity measurements of moving or deforming objects, determination of the shape and local declination of mirrors, lenses, eyeglasses and head-up displays or the measurement of glass panes thickness.