BALIS

Reducing greenhouse gas emissions in aviation is a challenging and largely unresolved task. While sustainable aviation fuels are currently being pursued for long-haul aircraft, fuel cell technology offers a promising alternative for regional aircraft, for example. This technology makes it possible to provide electrical energy from the reaction energy of green hydrogen and oxygen and at the same time avoid greenhouse gas emissions. In order to enable regional aircraft with 40 to 60 seats and a range of 1,000 kilometres, a considerable upscaling of the existing components is required. Previous demonstration flights have been in the order of around 600kW1 of fuel cell power.

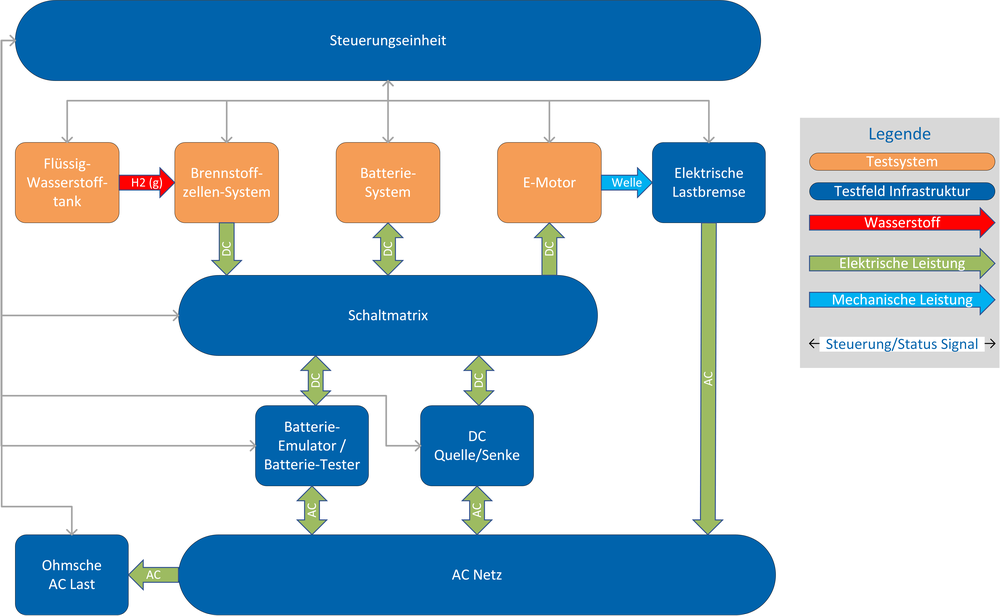

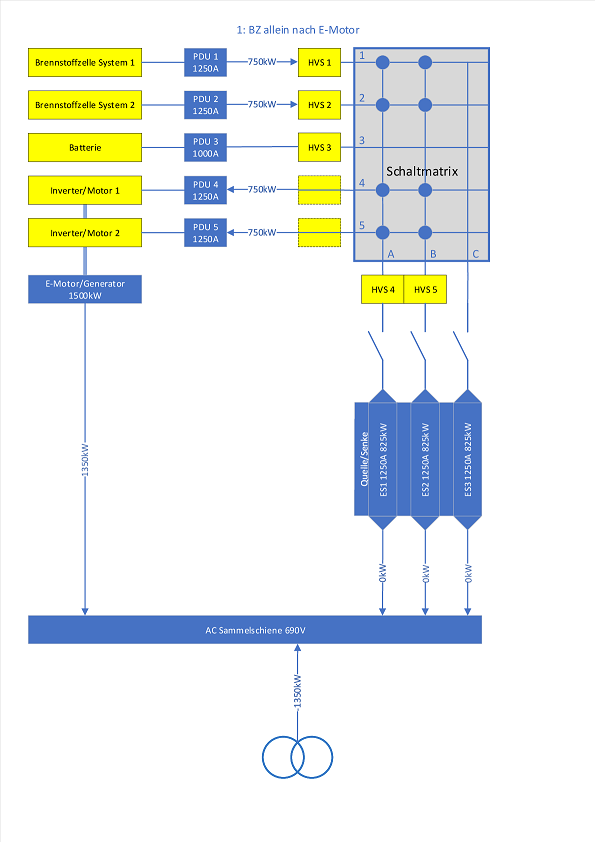

To demonstrate this upscaling to 1.5 MW, DLR has built a unique test environment with several industrial partners as part of the BALIS project (fuel cell-based powertrain for aircraft 1.5+ MW). The core components consist of a fuel cell system, a tank for liquid hydrogen, a high-performance electric motor, a battery and the control and regulation technology, including the associated infrastructure (see Figure 1). The components can be operated and tested both individually and in combination via a switching matrix. This makes it possible to simulate and analyse any load cases for an aircraft for each component and the overall system.

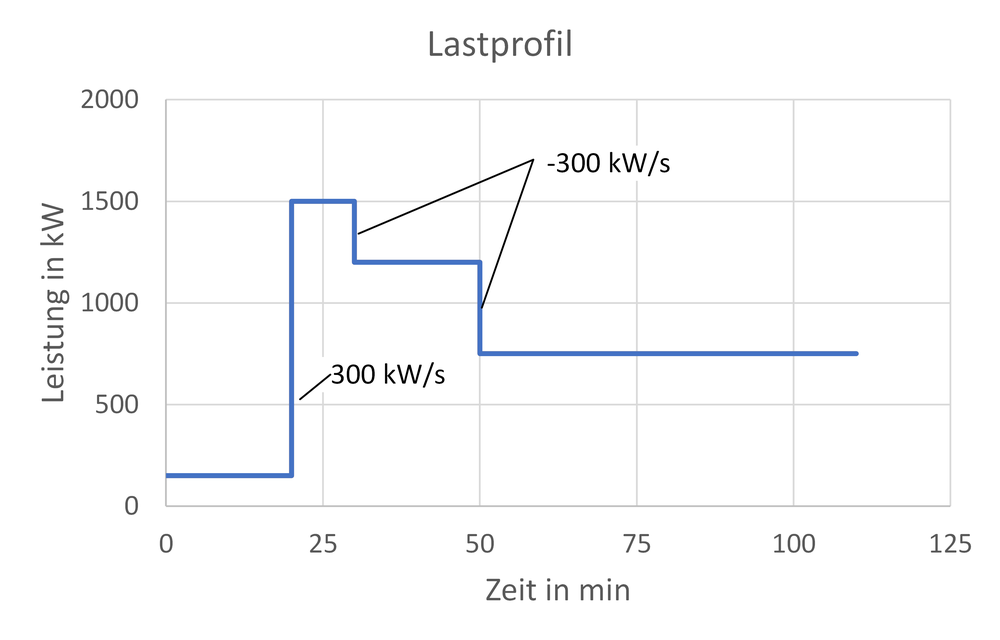

An exemplary load profile is shown in Figure 2. Here, the movement to the runway is first simulated at a low speed. During the subsequent take-off phase, the maximum system power is called up for 10 minutes. The aircraft then climbs to the desired cruising altitude within 20 minutes at a high power of 1.2 MW, which is then maintained for 60 minutes at medium power.

The test environment, funded by the Federal Ministry of Transport and Digital Infrastructure (BMVI) with 26 million euros, is being set up in several modular containers on the Innovation Campus Empfingen near Stuttgart. Coordinated by DLR, the industrial system developer AVL has set up the necessary measurement and testing infrastructure. The flight-relevant core components have been developed in collaboration with several technology partners and integrated into the test environment. Construction began in October 2021 and the entire system was demonstrated until the end of the project in June 2023.

The BALIS test environment makes it possible to realistically and easily test both the core components of a powertrain based on fuel cells and/or batteries and their effect on the entire drive system. The test environment can therefore contribute to faster development of the components and thus accelerate the market readiness of fuel cell or battery-based aviation systems.

1 Universal hydrogen Co, K. Gundry, Universal Hydrogen Successfully Completes First Flight of Hydrogen Regional Airliner, Press Release; March 2, 2023