Joule-Flex

Energy is increasingly being supplied from renewable sources. It is therefore becoming increasingly important to provide electricity flexibly so that it is always available exactly when it is needed. In the heating sector, a corresponding reorganisation is being sought. The future dismantling of fossil-fuelled combined heat and power generation increases the urgency for efficient solutions here.

Efficient and operationally flexible solutions for power-to-heat technologies and alternative fuels in centralised and decentralised applications are therefore necessary for the upcoming switch to heat generated using renewable energies.

Two favoured technologies of different performance classes are based on

- micro gas turbines with a systemically integrated and electrically heated solid fuel heat storage system and

- large-scale Brayton process-based Carnot batteries.

Thanks to its decentralised approach and fuel-flexible combustion systems, the micro gas turbine with integrated electrically heated solid fuel heat storage opens up great market potential for commercial combined heat and power applications as well as applications in residential areas.

Large-scale Brayton process-based Carnot batteries, on the other hand, offer greater flexibility and efficiency for industrial applications and grid stability due to their typical power plant size.

Successful further development of these two technologies towards experimental testing and investigation of system dynamics is therefore at the heart of the JouleFlex project. For the storage-supported micro gas turbine, this includes the development of a load-flexible combustion chamber, an inductive high-temperature electric heater for the solid fuel storage system and holistic, experimental testing via virtual coupling of the subsystems. For the Brayton battery, the work includes analysing the dynamic aspects of components and systems to assess the potential for use, particularly for various target markets for combined heat, power and cooling.

Central research and development tasks

- Development of a combustion chamber with variable orifice geometry (integrated high-temperature valve mechanism for load-independent dynamic adjustment of the fuel/air ratio in the combustion chamber for low pollutant emissions over a wide operating range) to significantly reduce exhaust emissions over the entire load range of a microturbine and preheating range of the high-temperature heat accumulator

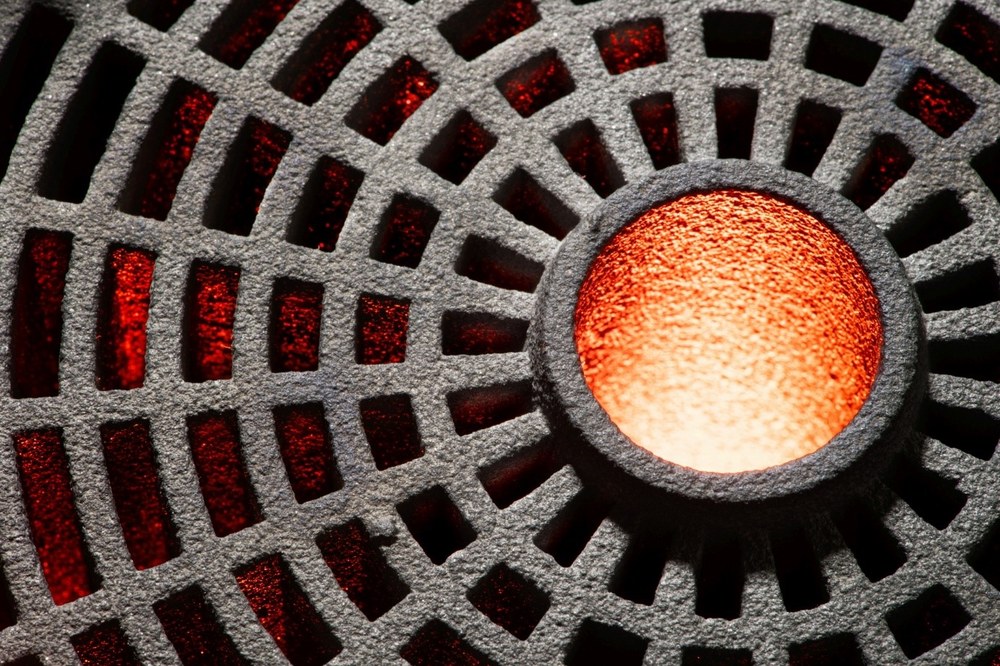

- Development of an induction heater for operating temperatures of over 1000 °C with high power-to-heat efficiency

- Development of compact high-temperature solid fuel heat accumulators for decentralised applications with low heat losses

- Process simulations to investigate the most promising way of integrating high-temperature heat accumulators into microturbines and their mode of operation

- Construction and operation of harmonised microturbine and inductively heated high-temperature storage test benches to demonstrate virtually coupled operation

- Development of dynamic system models for Brayton process-based Carnot batteries for megawatt/gigawatt-scale applications

- Identification of system configurations and operating strategies to evaluate the application potential of Carnot batteries for different target markets of combined heat, power and cooling.

Joule-Flex at a glance

Duration |

|

Project partners | Institute of Combustion Technology (DLR-VT)

|