BALU® research autoclave

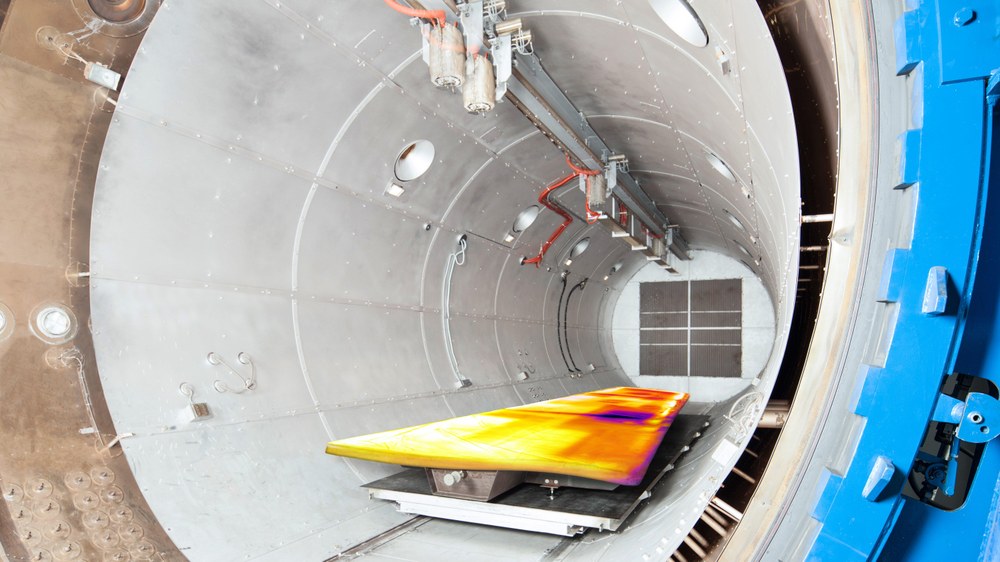

At the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) site in Stade, the DLR Institute of Composite Structures and Adaptive Systems operates the largest research autoclave in the world. The Biggest Autoclave Laboratory Uni (BALU®) is used to research new technologies in the field of lightweight composite structures.

Optimising the production of carbon-fibre-reinforced polymers

An autoclave is a pressure-sealed oven that is used to cure components made of Carbon-Fibre-Reinforced Polymers (CFRP) in a vacuum. The objective of the research carried out at Center for Lightweight-Production-Technology is to optimise infusion and curing processes for fibre-composite components on an industrial scale. To date, the system has been used for applications in the fields of aeronautics, space, transport, wind power and energy.

A large proportion of national and international projects deal with the primary structures of aircraft, such as fuselage segments and wing shells made from a diverse range of materials. At the facility, aluminium (relaxation forming) and fibre-metal laminates (fuselage shells) are just as well represented as CFRP (for example, toolmaking, among other things).

The research autoclave in Stade is also increasingly being used as a testing platform for digitalisation and Industry 4.0. To this end, a patented concept for the curing process is being tested and validated in combination with a digital twin. Users include stakeholders across the entire supply chain; for example, original equipment manufacturers, component manufacturers, material suppliers, end users and system manufacturers.