Electron microscopy and microanalysis (EMA)

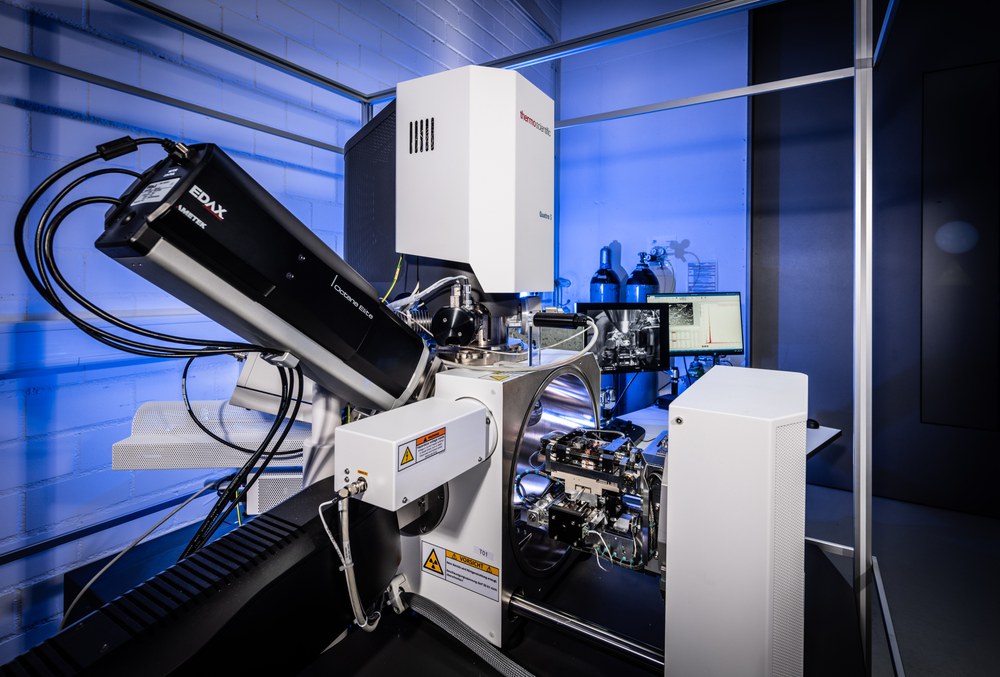

The large-scale facility at the DLR Institute of Test and Simulation for Gas Turbines in Augsburg is used for microanalytical investigations of materials from the engine and general turbomachinery sectors. The data obtained helps researchers understand degradation mechanisms caused by oxidation, corrosion and mechanical fatigue across a wide range of scales at temperatures of up to 1400 degrees Celsius. The data is also used to validate service life models developed at the Institute.

The scanning electron microscope features an ESEM mode (Environmental Scanning Electron Microscope), which enables the analysis of non-conductive and outgassing materials at pressures of up to 4000 pascals. Elemental analyses can be carried out using energy-dispersive X-ray spectroscopy (EDX), and the crystalline structures of materials can be examined using electron backscatter diffraction (EBSD). A heating module also enables in-situ imaging at high temperatures of up to 1400 degrees Celsius.

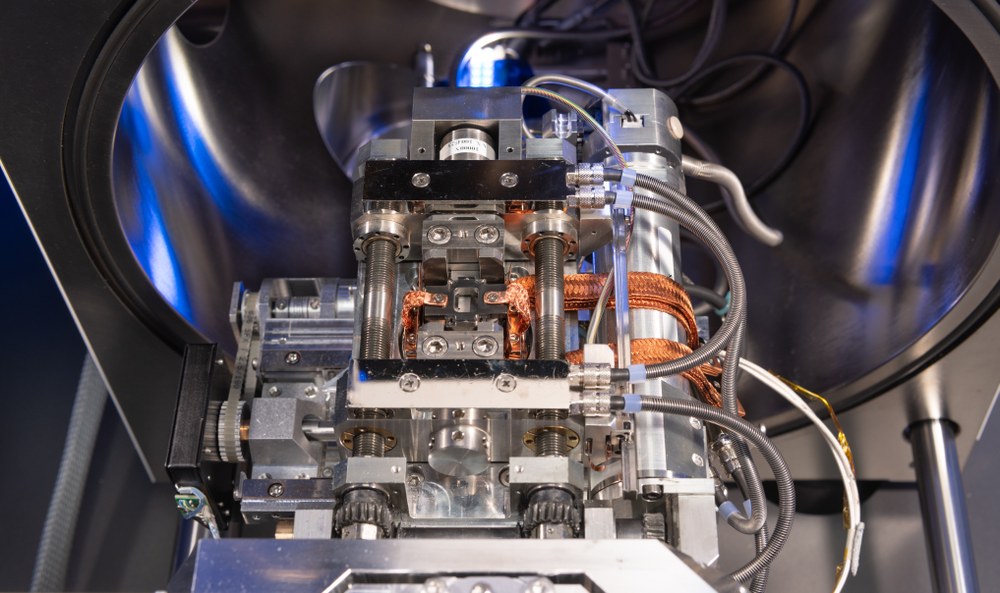

The MZ.HD micro-load frame is integrated into a Quattro S scanning electron microscope and used to investigate material damage at the micro scale under tensile or compressive stress at up to 1200 degrees Celsius, or under low-cycle fatigue (LCF) loading at room temperature. This setup enables in-situ analysis of crack formation and propagation under LCF conditions. Local strains at the micro scale can be measured using secondary electron imaging and digital image correlation.