Institute of Vehicle Concepts

The Institute of Vehicle Concepts is a system-oriented institute, handling and coordinating research subjects related to traffic and transportation at the DLR location in Stuttgart.

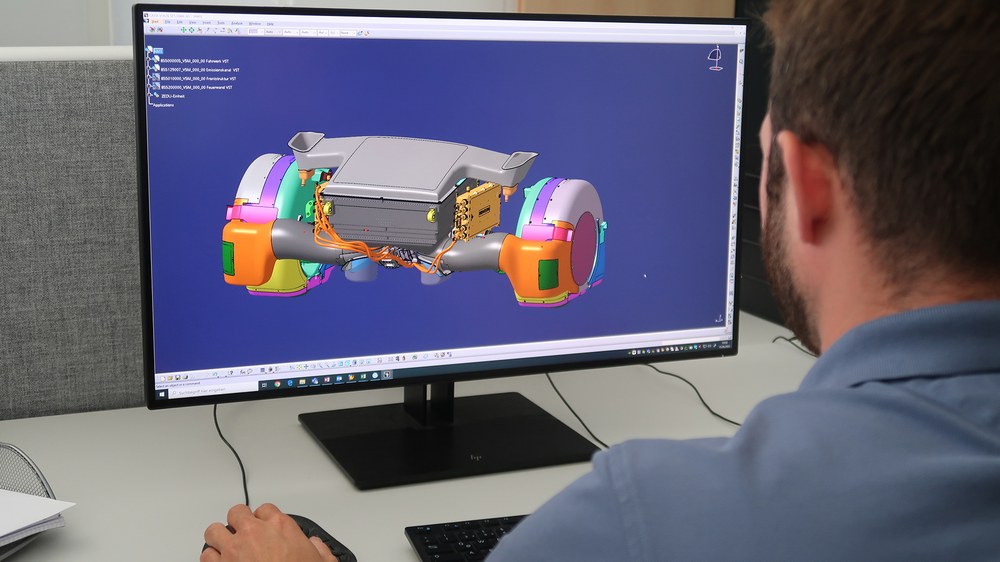

The release of exhaust fumes, particulate matter and microplastics are among the foremost contributors to environmental pollution linked to mobility. Together with the companies HWA AG and Frenoza GmbH, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) in Stuttgart (Institute of Vehicle Concepts and Institute of Combustion Technology) has committed to developing a sustainable, innovative and cost-effective solution. This solution aims to effectively mitigate the emission of ultrafine dust, particulate matter and microplastics resulting from road transport, thereby advancing the realisation of emission-free mobility. The Zero Emission Drive Unit (ZEDU-1) represents a significant step toward meeting the likely Euro 7 emissions standards expected to come into effect by 2025.

Further information on the premiere here.

Tyre abrasion on roads is responsible for more than a quarter of microplastic emissions worldwide. When it rains, these tiny particles make their way into the drainage system and thus into the water cycle. In Germany alone, this amounts to approximately 110,000 tonnes of matter a year. Braking also causes the abrasion of brake discs and brake pads. Over 90 percent of the resulting debris (5,500-8,000 tonnes per year) takes the form of ultrafine particles. These particles are considered to be particularly harmful to the environment and human health, as they can penetrate deep into our respiratory systems and become lodged there before entering the bloodstream. Transport-related abrasion thus contributes to poor air quality in cities as well as the health risk associated with road transport.

The project centres on advancing drive-relevant components that have been relatively overlooked in prior initiatives, yet hold intrinsic significance as emission sources across various forms of energy generation and operation: Brake units and tyre abrasion. Through the mitigation of emissions from these origins, mobility, when coupled with energy derived from renewable sources and electric propulsion, has the potential to achieve near-complete emission neutrality.

Together with the companies HWA, which was subcontracted with the design of the first-generation ZEDU-1 as the drive axle and the construction of the test vehicle, and Frenoza, which manufactures hard metal coatings for brakes, the project was successfully executed.

Technologically, the project represents a significant advancement. The braking system undergoes a fundamental shift, transitioning from the wheel carrier to the drive unit, where it is integrated. Through a synergistic combination of finely-tuned high-performance electronics, a power battery and a BBW system (Break-by-wire), the majority of braking energy can be effectively recuperated, thereby minimising reliance on mechanical braking components. This innovation facilitates the construction of an exceptionally compact drive unit, integrated into the transmission brake unit, while entirely eliminating brake wear emissions.

Various brake concepts were analysed and combined for this purpose. Two innovative systems were realised and investigated. Firstly, a specially developed multi-disc brake; operating mechanically as a closed system. The low level of brake abrasion is transported by the oil, which is also used for cooling and lubrication, into a filter and contained there. Secondly, an induction brake; exhibiting nearly negligible wear even down to a standstill, it harnesses magnetic fields to generate braking force.

A newly designed wheel arch reduces tyre wear emissions to a minimum. It is aerodynamically designed in such a way that the negative pressure created or generated while driving absorbs and collects the abrasion via a filter system.

The components developed in the project were realised and integrated into a specially constructed test and measurement vehicle. During test drives on the road, on a test site and on the DLR chassis dynamometer, a reference vehicle and the ZEDU-1 demonstrator were measured and metrological proof of the effectiveness of the developed components with regard to the emission of ultrafine particulate matter, fine particulate matter and microplastic abrasion was provided under real conditions. The characterisation primarily centres on the usability of the developed components in real operation and the evaluation of the total amount of fine dust and ultrafine dust emissions, the size distribution of the particles and their morphological determination in the analyses.

The Baden-Württemberg Ministry of Economic Affairs, Labour and Tourism is funding the project with a total of six million euros.

HWA

MANN+HUMMEL

Continental