MikroliqFLOX

Liquid energy carriers from renewable sources, produced with the help of renewable energies, are crucial for the energy system of the future due to their high energy densities and simple storage and transport options. In the future, these fuels will be produced in plants of different sizes and, depending on the raw material, through different production processes. However, the variety of available fuels (namely their physical and chemical properties) is a challenge for future energy conversion systems. With the MikroliqFLOX project, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) is developing a load-flexible burner system that can be used to convert micro gas turbines from gaseous to liquid energy sources. To achieve this, a new nozzle concept and a virtual injector are being developed.

Micro gas turbines are particularly well-suited for reconverting renewable fuels and for decentralised electricity and heat supply, due to their high fuel flexibility and low pollutant levels. Additionally, they can act as energy suppliers at both centralised and decentralised locations during periods of high fluctuation in renewable energy production. Achieving a high level of fuel flexibility with low emissions can only be achieved with new burner technologies if the advantages of gas turbines are to be fully utilised.

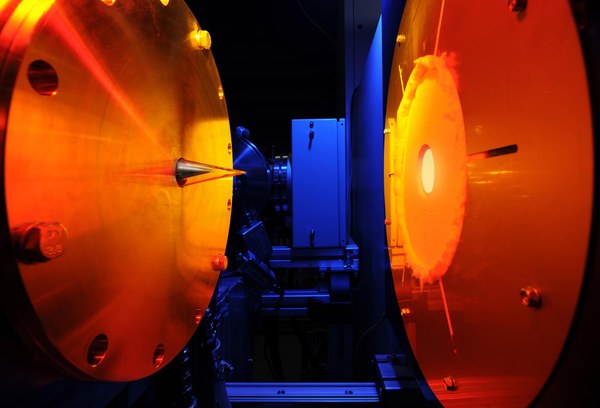

The DLR Institute of Combustion Technology is researching the conversion of gas turbines to operate with new fuels. For this purpose, the institute utilises several unique high-pressure test stands. The MikroliqFLOX project builds on the institute’s existing research in injector and burner technology. The abbreviation FLOX stands for flameless oxidation and refers to the barely visible flames produced when the concept was first applied in industrial burners. The concept has since been further developed at the institute in collaboration with industry and optimised for gas turbines of all kinds.

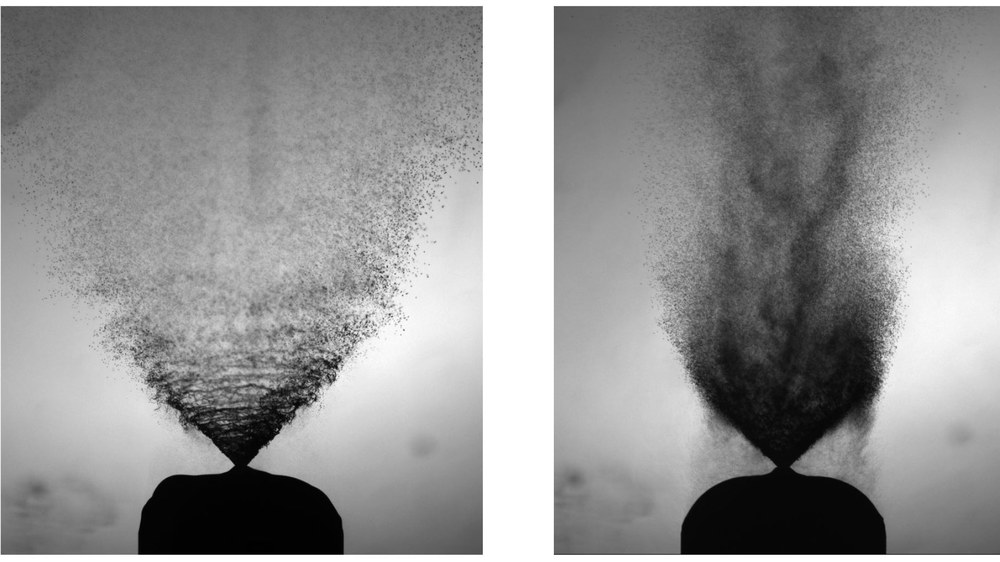

The characteristic feature of the jet-stabilised combustion concept is the injection of fuel-air mixtures into the combustion chamber using nozzles. These mixtures are introduced as jets with high flow velocities. The arrangement of these jets creates a pronounced recirculation zone within the combustion chamber. Fuel, air and recirculated exhaust gas are thoroughly mixed before combustion begins. This process avoids local temperature peaks and a strong nitrogen oxide formation in the flame. Burners employing this technology are distinguished by their low pollutant emissions, high fuel flexibility and excellent stability – properties that are essential for future energy systems.

In the MikroliqFLOX project, newly developed nozzle concepts are being further investigated and optimised through tests in the high-pressure test stands as scaled, compact individual nozzles. These test stands replicate conditions similar to those found in practical application. Following these investigations, a multi-nozzle burner will be developed through a step-by-step scaling process. The project aims to significantly improve the technological maturity of a fuel- and load-flexible FLOX burner system for liquid fuels, particularly in geometrically compact combustion chambers.

Simultaneously, a virtual injector is being developed, informed by the experimental data obtained during testing. This parallel development enables new methods for predicting key phenomena, such as internal flows within the injector, flame feedback and phase transitions.

With the novel injection concept, along with the design and production of a multi-nozzle burner and a virtual injector, two core technologies are being developed that can be further researched independently. Advanced experimental and numerical methods are also being developed for future AI-based data analysis, tailored specifically for future third-party-funded projects. As a result, the project enables technology transfer on several levels, benefiting both research and industry.

MikroliqFLOX project – development of compact jet-stabilised gas turbine burner systems for liquid energy carriers

- Duration: 1 January 2022 to 31 December 2025

- Leading institute: DLR Institute of Combustion Technology

- Project type: basic funding, DLR Impulse Project

- Funding body: DLR Energy Programme Directorate