RETALT – Research into vertical landing

As part of the EU's Horizon 2020 research and innovation programme, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) has joined forces with five industry partners in the RETALT (RETro propulsion Assisted Landing Technologies) project. Between 2019 and 2022, this joint effort focused on advancing European re-entry technologies by researching rockets capable of vertical reverse landings. The consortium investigated various technical aspects, in particular aerodynamics, surface temperatures during flight (aerothermodynamics), flight dynamics, navigation and control systems, as well as structural components, materials and mechanisms. Although the Falcon 9 rocket from the US company SpaceX already utilises vertical landing systems, the complex physics of the entire flight process have not yet been researched in detail, leaving gaps in fundamental data.

The RETALT project examined two configurations for vertically launching and landing rockets:

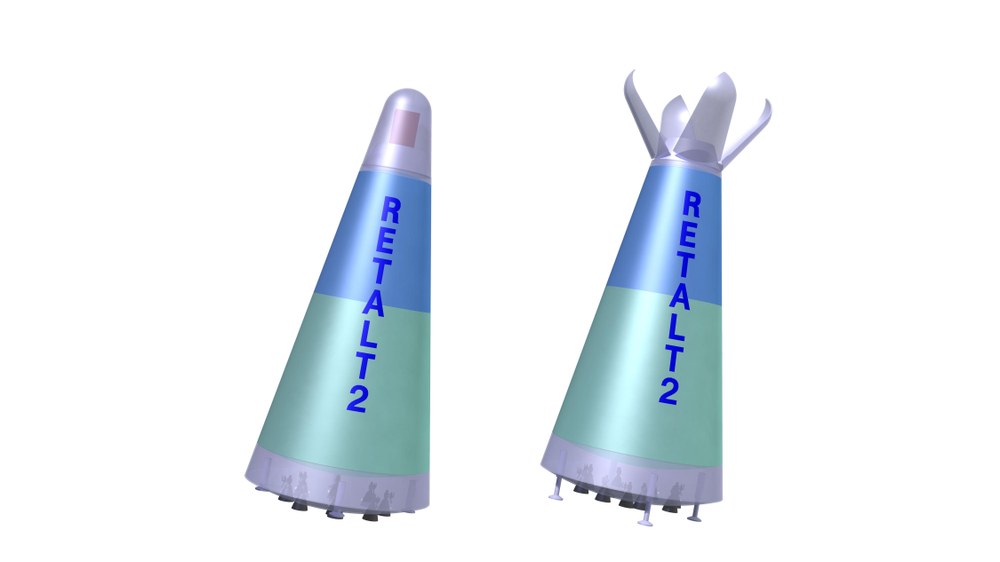

- RETALT1 is a two-stage launcher based on established rocket designs like the Falcon 9 and the European Ariane 5. The goal was to enable the first stage of the launch vehicle to return and land vertically.

- RETALT2 is a single-stage launcher, considered more of an 'academic configuration'. The aim of this design was to return to Earth using both retro propulsion and a large aerodynamic surface on the underside for deceleration.

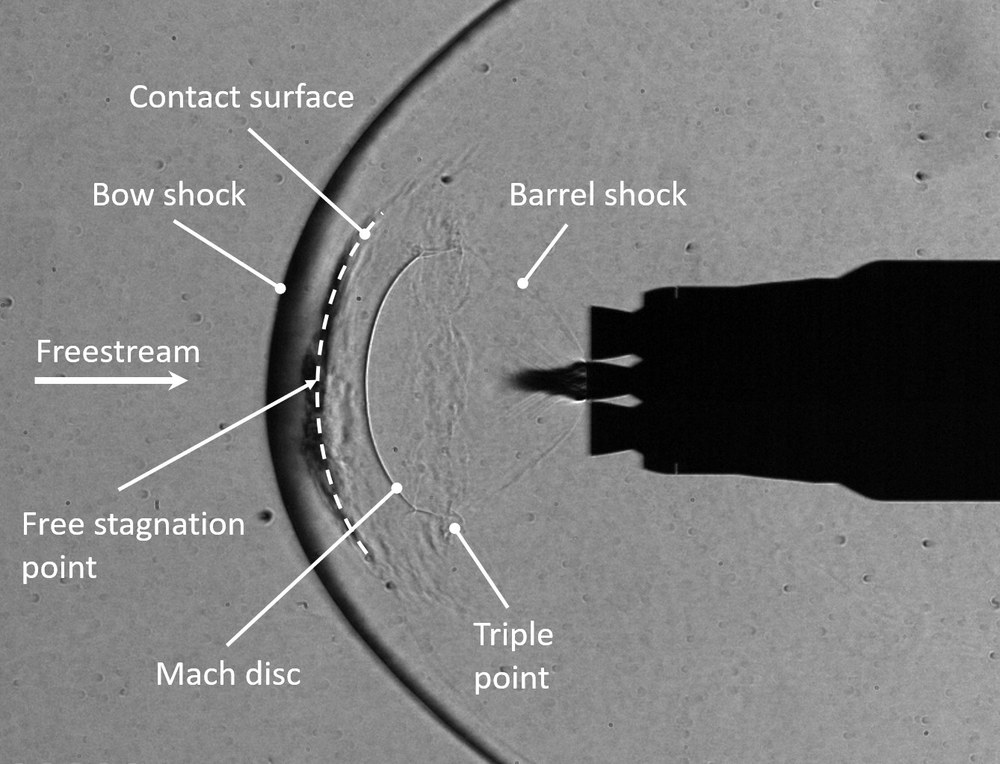

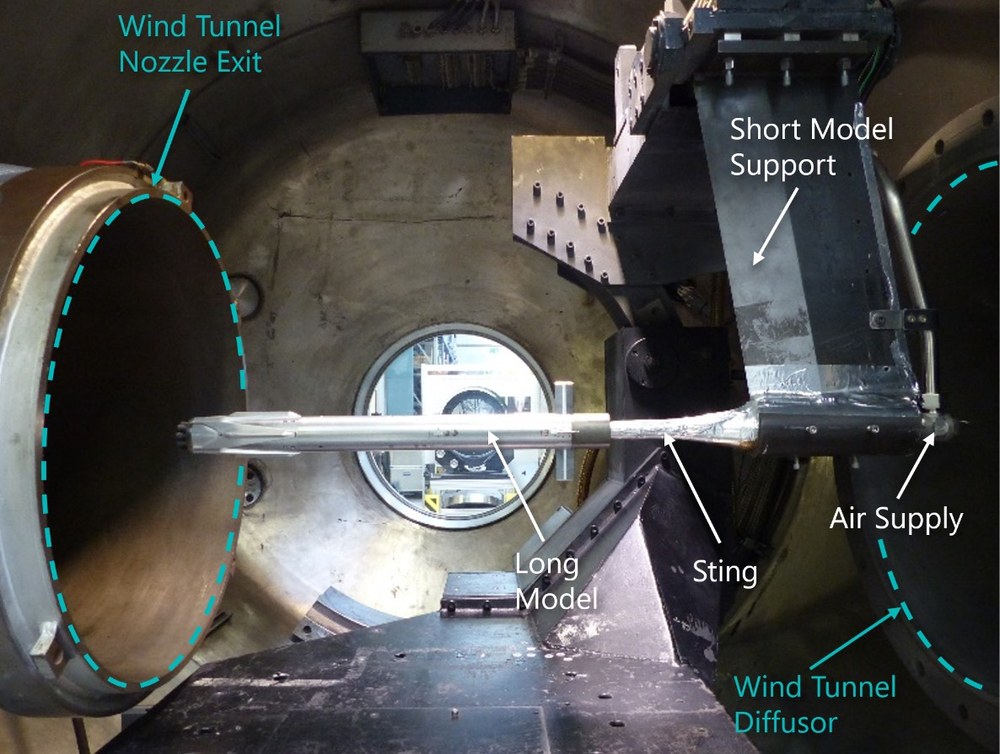

The aerodynamics of these concepts were tested using 1:100 scale models in DLR wind tunnels. Researchers tested braking manoeuvres by igniting engines at hypersonic speeds in the H2K hypersonic wind tunnel with compressed air, followed by studying the aerodynamic flight phase in the trisonic wind tunnel (TMK). The final landing ignition, using hydrogen-oxygen combustion, was tested using a model with an integrated combustion chamber in the vertical test section (VMK). All three test rigs are in Cologne. At larger scales of up to 1:5, the RETALT consortium created demonstrators to analyse structural components such as landing legs. The results of these tests form the foundation for future projects, where prototypes will be constructed and eventually tested in space.

The DLR Institute of Aerodynamics and Flow Technology served as the project coordinator and was scientifically involved in RETALT through its Supersonic and Hypersonic Technologies Department at DLR's site in Cologne and its Spacecraft Department in Göttingen. The Supersonic and Hypersonic Technologies teams coordinated the project and were responsible for the design of the reference configurations, along with the evaluation of aerodynamics and aerothermodynamic behaviour during wind tunnel testing. The spacecraft department characterised the aerothermodynamics of the configurations and produced numerical flow simulations.

Throughout the project, numerous conference and scientific journal articles were published, all of which are available online via the EU Open Research Repository, Zenodo.

A new milestone on the path to vertical landing in Europe

After three and a half years of research into propulsion-based landing technologies, the RETALT project concluded in late summer 2022. The research resulted in the acquisition of valuable expertise, new methods, tools and a wealth of data. However, the RETALT legacy continues, as work towards the vision of achieving vertical landing in Europe will progress through the SALTO project (reuSable strAtegic space Launcher Technologies and Operations), in which the RETALT partners are once again involved.

Examples of new methods and tools developed from RETALT

- Methodologies for creating aerodynamic and aerothermal databases, which enable the development of holistic aerodynamic and aerothermal models for the launchers, were further developed.

- Analytical models were developed to design the control surfaces of these configurations.

- For the first time, wind tunnel tests were conducted that simulated an engine jet directed against the flow using cold gas. To this end, the team developed and analysed new similarity parameters in order to design these experiments and modify the test facilities accordingly.

- Additionally, tests with a hot exhaust gas stream, using hydrogen-oxygen combustion, were successfully carried out in the wind tunnel model for the first time.

Through close collaboration with other organisations in the RETALT consortium, the team gained a deeper understanding of the interdependencies between various technological areas, allowing for a more comprehensive view of how these systems function.

Related links

- Whitepaper: Sustainable space technologies – Strategies toward a predictive aerothermal design of re-useable space transportation systems (February 2024)

- DLR Institute of Aerodynamics and Flow Technology

- Department Supersonic and Hypersonic Technologies

- Department Spacecraft

- More about the Hypersonic wind tunnel (H2K)

- More about the Vertical test section (VMK)

- More about the Trisonic wind tunnel (TMK)

About RETALT

The RETALT project received funding from the European Union's Horizon 2020 research and innovation framework programme under grant agreement No. 821890. In addition to the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR), the project involved: Almatech SA, Amorim Cork Composites SA, CFS Engineering SA, Deimos Space - Sociedad Limitada Unipersonal and MT Aerospace AG.