Electrolysis and solar processes

DLR research is concentrated on two methods for producing green hydrogen on a large industrial scale – electrolysis and solar-thermal processes.

Electrolysis is the most well-developed technique and is already commercially available. The principle of using electricity to split water into hydrogen and oxygen has been known for more than 200 years. Today, research is focussed on alkaline, proton-exchange membrane and high-temperature electrolysis processes, and DLR is further developing all three. Germany currently has a total electrolysis capacity of 30 megawatts, powered by renewable energy. To support a hydrogen economy, this capacity would have to be greatly expanded and divided between smaller, decentralised electrolysis systems – at filling stations, perhaps – and centralised, large-scale electrolysers with particularly high efficiencies.

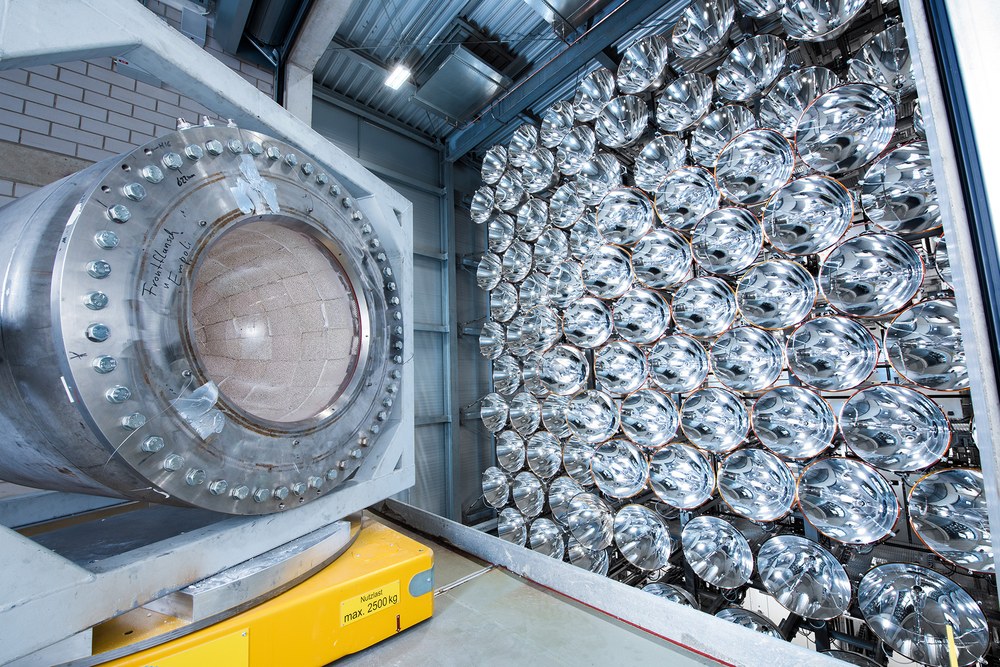

Solar-thermal hydrogen production promises to be more efficient, by converting concentrated solar radiation into electricity and heat. In this process, concentrated solar energy is used to produce heat for thermochemical water splitting. Solar-thermal plants are best located along the equatorial Sun belt, supplying hydrogen in a manner analogous to the trade in fossil fuels. DLR is working to develop components and processes that will allow such systems to be efficient, durable and suitable for large-scale industrial use. The first pilot plants are already in operation, but it will take several years before solar hydrogen production processes are ready for the market.

Example projects:

- ASTOR – In the ASTOR (Automation of Solar-Thermochemical processes to reduce hydrogen production costs) research project, a solar-thermal reactor is being developed to generate hydrogen from solar energy and water.

- H2ORIZON – Renewable hydrogen generation using proton-exchange membrane electrolysis based on wind-derived energy.