Anniversary: 10 years EML onboard the ISS

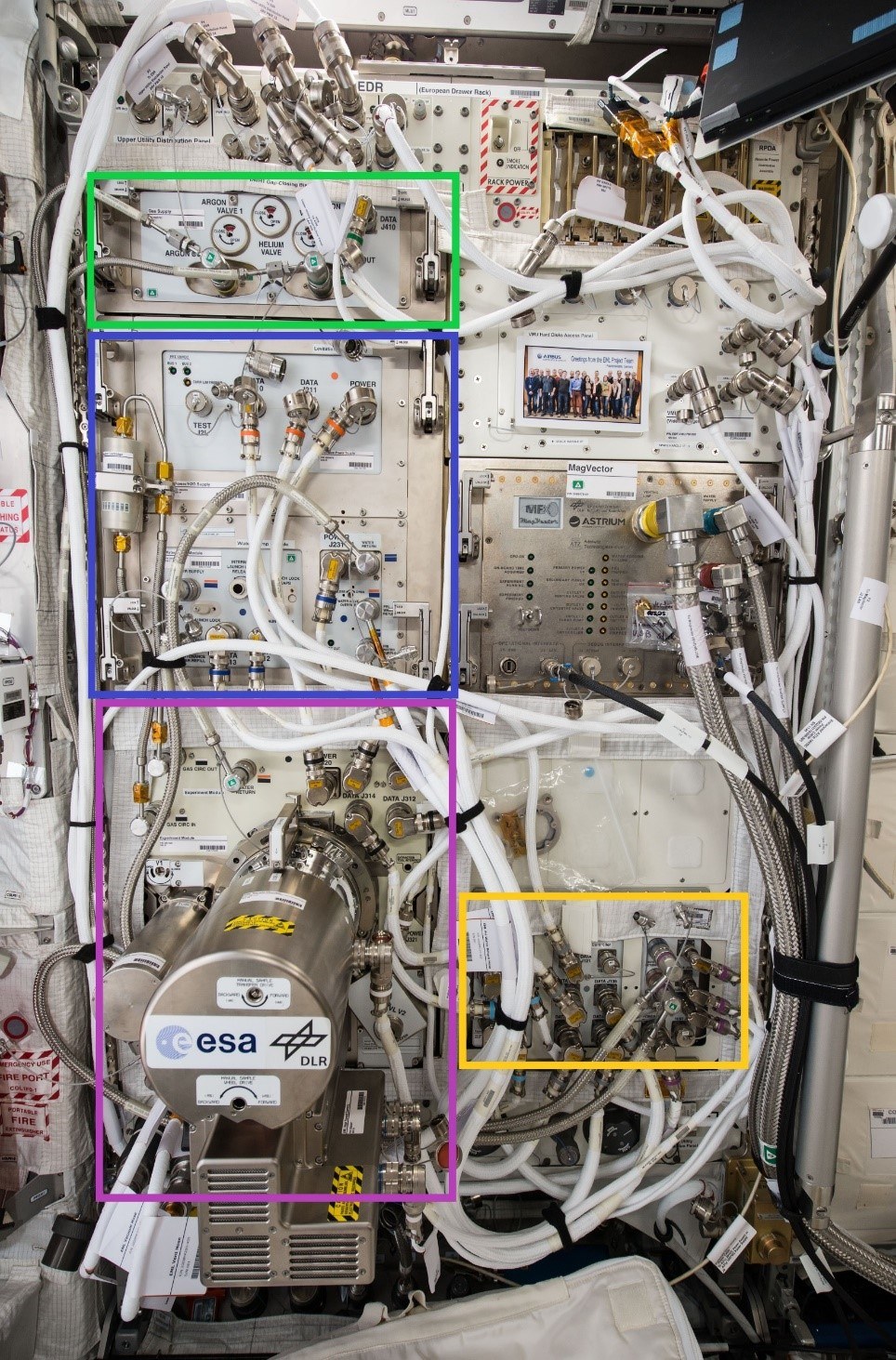

On October 31 at 9:59 am in the year 2014, i.e. 10 years ago, the electromagnetic levitator (EML) was switched on for the first time onboard the International Space Station (ISS). The EML is a research facility that was installed by German astronaut Alexander Gerst in the European Drawer Rack (EDR) within the Columbus module onboard the ISS. The EML system was financed by ESA and DLR and constructed in modular form by Airbus DS, based on more than 30 years of development, testing and scientific experimentation at our institute.

The facility is of great importance to materials scientists and is used by international research groups. Using electromagnetic fields, metal samples are positioned and melted free-floating in a coil by means of an alternating electromagnetic field. This allows the precise analyzation of material properties at various temperatures in the liquid state until solidification and partly in the solid state as well. The floating, liquid samples are analyzed, for example, with regard to thermophysical properties such as viscosity, surface tension, density, electrical conductivity and specific heat. This is done without any contact with a crucible wall, which could impair the measurement accuracy. Due to the lack of gravity and the container-free processing of the sample, the EML enables unique measurements of high precision, even in the metastable state of the supercooled melt.

Investigations into the solidification behavior of liquid samples in particular benefit from the EML's unique process technology. In addition to the solidification rate (Fig. 4), other solidification phenomena such as the delay between the solidification of several metastable and stable solid or melt phases and their dependence on the convection (stimulated by "electromagnetic stirring" of the various fields) of the sample are also investigated.

For a comparison with thermohydraulic simulations, samples can also be solidified on a chill-cooling sample holder and cooled rapidly. A comparison of the simulated and measured shape of the solidifying sample helps to improve the solidification model (see Fig. 5).

In 2017, the EML was expanded to include SCE - Sample Coupling Electronics. This instrument allows non-contact measurement of the electrical conductivity of liquid samples and was developed at the Institute of Materials Physics in Space. In addition to measuring the thermophysical quantity, deviations in the electrical conductivity from the linear behavior indicate structural changes in the undercooled melt.

The EML provides a laboratory with a wide range of possibilities. Metal alloys and semiconductor samples can be processed in the range from 300 to 2100 degrees Celsius from melt to solid. During processing, researchers on Earth receive real-time data and video recordings. This allows them to intervene in the process "live". The experiments are carried out from the control room of the DLR Microgravity User Support Centre (MUSC) in Cologne. Due to the delay time that the signal needs to get from MUSC, via TDRIS satellites to EML onboard the ISS and back, the high-speed camera recordings, that can be done with up to 45000 Hz, are automatically triggered by a recalescence detection algorithm.

In the last 10 years of EML operation, 3 EML sample batches have been planned, prepared, validated and carried out by DLR-MP staff at the Cologne site. Each EML batch consists of 18 samples that can be accommodated simultaneously in the EML sample chamber. Each sample was characterized in ground-based measurements and then qualified for usage in ISS-EML in microgravity experiments with the EML facility TEMPUS in parabolic flights. Several experimental measurements, also known as cycles, are carried out on each sample. These measurements take place at night, during the official "crew sleep" on the ISS, in order to minimize the influence of crew activities on the residual accelerations in Columbus. Supporting crew activities during daytime hours include mechanical changes to the camera mode and gas configuration. A total of 54 samples have been processed since 2014 and the facility has been used for over 500 days. By far more than 100,000 commands have been sent from the control room to the ISS to carry out the experiments. The fourth sample chamber is currently attached to the EML and the program will continue in the future with the 18 integrated samples. Furthermore, EML is continuously being upgraded. The next upgrade will be the addition of an oxygen control and sensor unit (OCS), that should be uploaded in the frame of batch 4 and shall be able to passively measure and actively control the oxygen partial pressure in the process chamber of EML onboard the ISS. Currently a ground support program is running in order to find out the optimum usage scenarios of that upgrade system.