BiG C.R.O.P.®: Biological slurry treatment

Originally, C.R.O.P.® was developed at the Institute of Aerospace Medicine of the German Aerospace Center (DLR) as a process for recycling nitrogenous wastewater in closed habitats such as Moon or Mars stations. By converting human urine into a plant fertilizer, astronauts are able to cultivate fresh food in greenhouses. This process can also be transferred to agricultural applications and enables the biological production of high-quality fertilizers in liquid and solid form.

The manure problem

Prices for industrially produced mineral fertilizers have been at a very high level for months. If fertilizer is not available to farmers in sufficient quantities, the use of mineral fertilizers must be reduced. A shortage of nitrogen, for example, leads to lower yields as well as quality losses in important arable crops such as corn, wheat or barley. Nitrogen fertilizers from organic sources such as liquid manure or fermentation residues are therefore increasingly in demand. One challenge, however, is the imprecise nutrient delivery from farm manures, which often makes it difficult to assess the fertilization effect. In addition, the ecosystems of soil, water and air are extremely polluted by the excessive application of liquid manure and the nitrogen it contains. The C.R.O.P.® process can reduce the use of expensive mineral fertilizers and protect the environment.

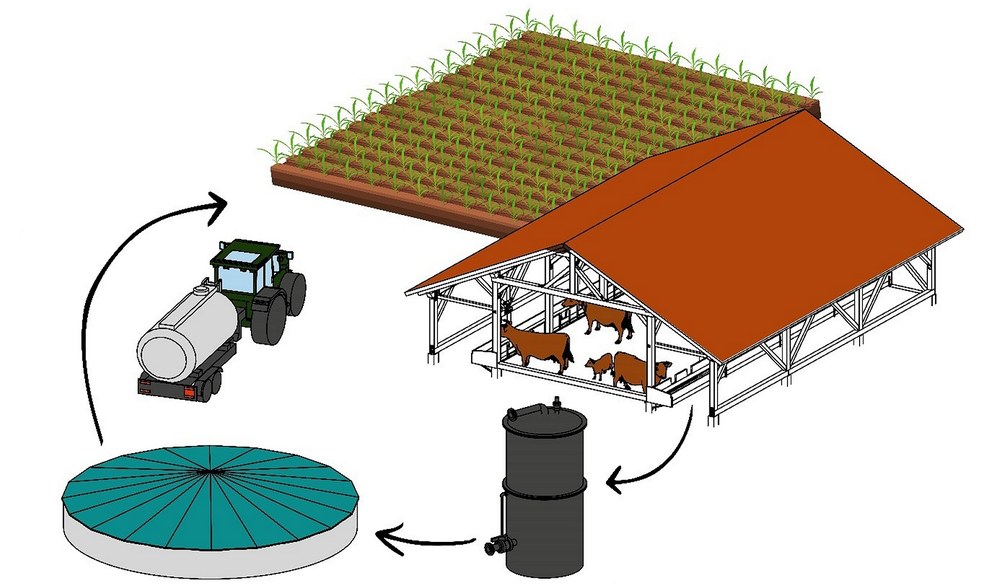

Closed loops with natural resources

The aim is to obtain a fertilizer directly available to plants by processing manure and fermentation products using C.R.O.P.® technology and to implement regional nutrient cycles. After processing, a liquid and a solid fertilizer are created. The liquid fertilizer solution contains forms of nitrogen directly available to the plant and can be applied to the field using conventional slurry technology. The solid fertilizer contains high levels of organic matter and can thus help build humus for healthy soil. These biologically produced fertilizers can reduce uncontrolled nitrogen applications to the soil, air and water ecosystems and prevent emissions of environmental toxins (e.g. ammonia). Thus, the characteristic odor of liquid manure is no longer produced during application, which additionally increases the social acceptance of farm manure. After treatment with the C.R.O.P.® process, the nutrients contained in the manure are present in stable, non-volatile nitrogen compounds and loss-free storage of the manure is made possible.

Function and structure

The C.R.O.P.® technology completely avoids the use of chemicals and hazardous substances, as the process is based on natural metabolic activities. A plant has a modular design and consists of a reaction chamber and a tank volume. The closed reaction chamber is located above the tank and contains carrier materials on which a large number of microorganisms settle. This allows optimum conditions to be set for the biological processes. Sufficient substrate is present in the tank volume, which is continuously circulated through the reaction chamber. The C.R.O.P.® fertilizer solution can be taken from this substrate and fresh, untreated slurry can be added. Due to the ongoing addition of separated slurry, a C.R.O.P.® treatment plant runs in continuous operation.

The simple process control with few technological components allows the plant to be easily integrated into the existing infrastructure of an agricultural operation and to be individually adapted. The process is low-maintenance and robust in the face of malfunctions, so that the system can regenerate independently and quickly after a possible power or pump failure. In addition, the system's energy requirements are low because the process runs at ambient pressure in a low temperature range.

Advantages of the C.R.O.P.® process

- directly plant-available, organic liquid fertilizer

- no odor nuisance during storage and spreading

- existing technology for manure application can be used

- good storage capacity without nutrient losses

- robust and low-maintenance process

- easy integration into farm structures

- high individuality due to modular design

- cost-effective and low-energy operation

- cost savings due to savings on mineral fertilizers

- improved environmental balance due to less emissions into the atmosphere

- improved soil and water protection

- implementation of an almost closed nutrient cycle in agriculture

Video: Project manager Tim Paulke explains BiG C.R.O.P.® (GERMAN)

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

Project | BiG C.R.O.P.®: Biologische Gülleaufbereitung |

|---|---|

Duration |