Water from Moon rock for future astronaut missions

Kevin M. Cannon/Colorado School of Mines

- An international team has tested technologies for extracting water from lunar regolith in the laboratory.

- DLR, together with other European project participants, has conducted laboratory experiments at TU Braunschweig to determine how ice can be extracted from simulated lunar dust.

- The water obtained is intended for use as drinking water, oxygen production or for the production of hydrogen-based rocket fuels in space.

- Focus: Space

Water extraction in space is immensely important for exploring the Solar System. Under the leadership of the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR), a method has been developed for this very purpose. The LUWEX research project (focussed on validating lunar water extraction and purification technologies for in-situ propellant and consumables production) has been experimentally testing this new process on a large scale over several months at the Technical University (TU) Braunschweig. The goal is to extract at least half a litre of water per experiment.

In the LUWEX project, researchers developed a process for extracting and purifying water from ice-containing lunar dust (regolith) to provide rocket fuel and drinking water for future astronauts stationed on the Moon's surface. The method has now been successfully tested in experiments.

Paul Zabel from the DLR Institute of Space Systems in Bremen is pleased with the project result: "We exceeded our goal of producing at least half a litre of water in each test run. In the experiments, we were able to extract and process almost 65 percent of the water from the simulated Moon rock. In several experiments, we produced a total of more than three litres of clean water."

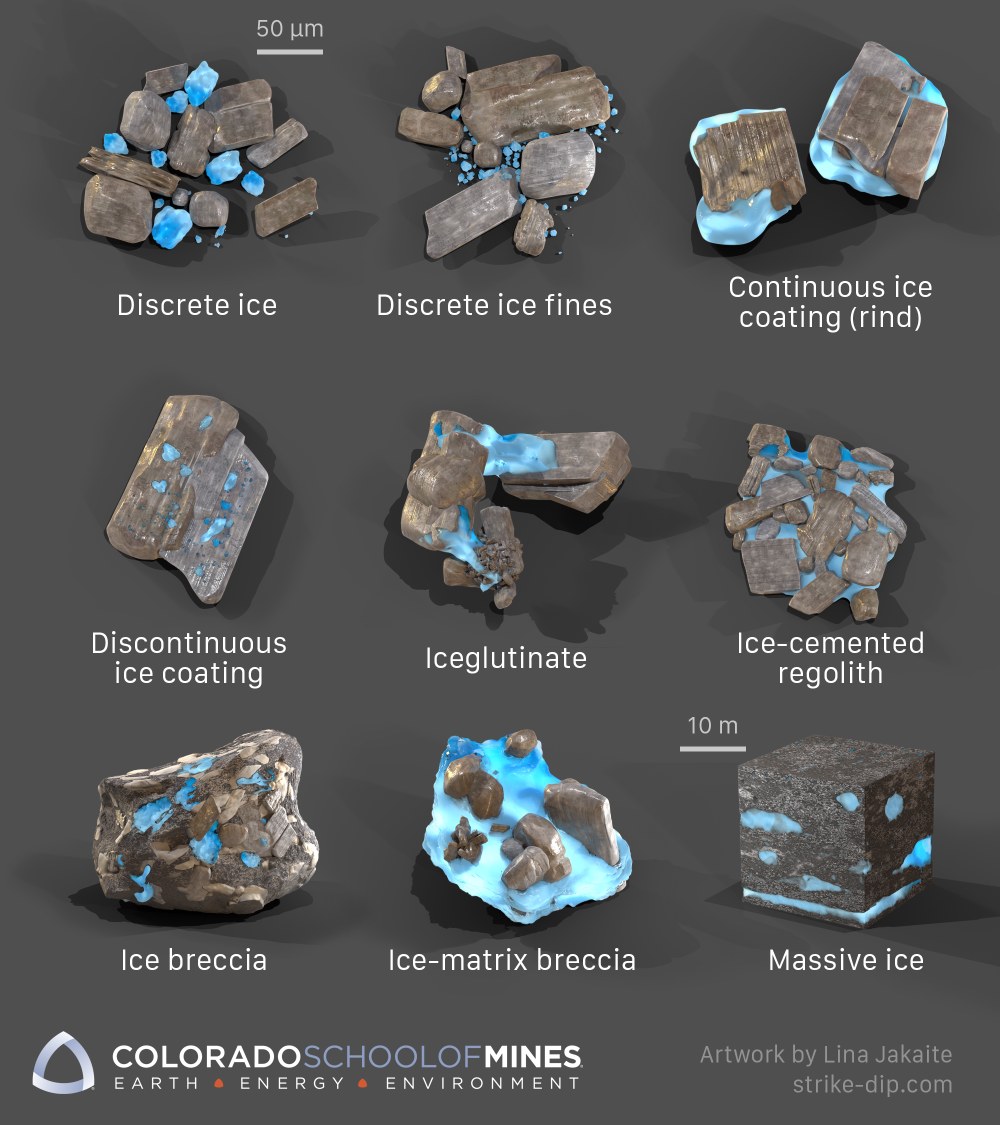

Icy lunar regolith made in the lab

At TU Braunschweig, the project team mixed ice and synthetic lunar regolith to create a dust-ice simulant, from which water could then be extracted in the thermal vacuum chamber of the CoPhyLab (Comet Physics Laboratory). To create the ice, a mist of very fine water droplets was shock-frozen in liquid nitrogen. This produces individual round water ice particles with a radius of 2.4 micrometres, which is approximately one-twentieth the width of a human hair. These are then mixed with the lunar regolith.

Lab conditions simulate the Moon

The lunar ice simulant was then placed in the DLR-developed water extraction system, located inside the thermal vacuum chamber which provided Moon-like conditions. After pumping out the remaining atmosphere, the simulant was heated and stirred to distribute the heat evenly. Due to the low pressure, the ice did not melt but instead was converted directly into water vapour. This gas then accumulated on copper pipes, which were cooled with liquid nitrogen to minus 150 degrees Celsius, where it condensed back into ice. The process separated the ice from the lunar regolith, and once enough ice was collected on the copper pipes, they were heated, causing the ice to slide down and liquefy into water. This subsystem for extracting water was developed at DLR’s site in Bremen. At the end of the experiment, the water was processed and its quality was checked.

Water extraction under Moon-like conditions

Researchers tested various samples with different proportions of lunar regolith and ice to identify the optimal process parameters for water extraction. The project aimed to extract the maximum amount of water on the Moon with minimal energy. One question was, which temperature and stirring speed would be best suited? Thales Alenia Space took the second step, processing and purifying the extracted water. Sensors measured the water quality and samples were analysed in detail and processed in the laboratory.

"This allowed us to successfully demonstrate how the overall system works under different conditions. This is an important step in the development of technologies for future lunar missions," says Paul Zabel.

Collaborative international cooperation

The interdisciplinary LUWEX team from Germany, Austria, Poland and Italy has set itself the goal of developing a novel water extraction system. Each project participant is providing one or more subsystems or infrastructures. In addition to DLR, the institutions and companies involved in the project were the Technical University of Braunschweig, LIQUIFER Systems Group, Thales Alenia Space, the Wroclaw University of Science and Technology and Scanway Space.