Retrofit for commercial micro gas turbines successfully tested

- DLR and the company PSC have conducted a retrofit of a commercial micro gas turbine for the first time.

- With the new burner and an adapted control system, the gas turbine can be operated with pure hydrogen as well as hydrogen mixtures with natural gas.

- Emissions of nitrogen oxides when using pure hydrogen are well below the limit values for operation with natural gas.

- A retrofit offers a cost-effective way to convert existing gas-fired power plants for climate-compatible operation with hydrogen.

- Focus: Energy, hydrogen

The German Aerospace Center (Deutsche Zentrum für Luft- und Raumfahrt; DLR) and the company Power Service Consulting (PSC) have, for the first time, converted a commercial micro gas turbine for climate-compatible operation with pure hydrogen. Test runs following this retrofit demonstrated exceptionally-low nitrogen oxide emissions.

As the construction of new power plants is time-consuming and expensive, it is worth retrofitting natural gas-fuelled gas turbines in existing plants to make them hydrogen-compatible.

Balancing dark doldrums and peak loads

To ensure a reliable and controllable supply of renewable energy, our energy system requires power plants that stabilise the grid. Today, gas-fired power plants already play an important role as peak load power plants, adjusting their output quickly and flexibly to compensate for load peaks or the 'dark doldrums' – periods without sunshine or wind.

Until now, gas turbine power plants have mostly burnt natural gas and therefore emitted carbon dioxide. Replacing natural gas with green hydrogen from renewable energy sources is a climate-compatible alternative. The DLR Institute of Combustion Technology in Stuttgart is conducting research into how gas turbines can operate with hydrogen as emission-free as possible.

Retrofit – converting instead of building anew

Building new power plants however costs money and time. It may therefore be worthwhile to convert existing plants to run on hydrogen. Such retrofit concepts can facilitate the transition to the hydrogen economy. "Building a new 15-megawatt gas turbine power plant takes approximately six years and costs around 30 million euros. On the other hand, retrofitting an existing plant takes only one and a half years and costs around a tenth of that," says Peter Kutne, Head of the Gas Turbines Department at the DLR Institute of Combustion Technology. Micro gas turbines with outputs of approximately 100 kilowatts are often used in hospitals, hotels or breweries to generate electricity and heat.

From natural gas to 100 percent hydrogen

In the Retrofit H2 project, DLR and PSC have completely retrofitted a pilot plant for the first time. Together, they have converted a micro gas turbine from Ansaldo Green Tech so that it can be operated with both pure hydrogen and hydrogen-natural gas mixtures. It is the first marketable retrofit concept for micro gas turbines.

DLR researcher Martina Hohloch and her team first replaced the turbine's combustion chamber with a hydrogen-compatible version developed at the institute. "The high chemical reactivity of hydrogen is particularly challenging. It has a flame speed around ten times greater than natural gas and the ignition energy is lower by the same factor. This makes safe combustion difficult," explains Hohloch, who is leading the project, and adds: "When developing the burner, we had to ensure that the flame would not flash back into the burner nozzles and damage them."

A first with pure hydrogen

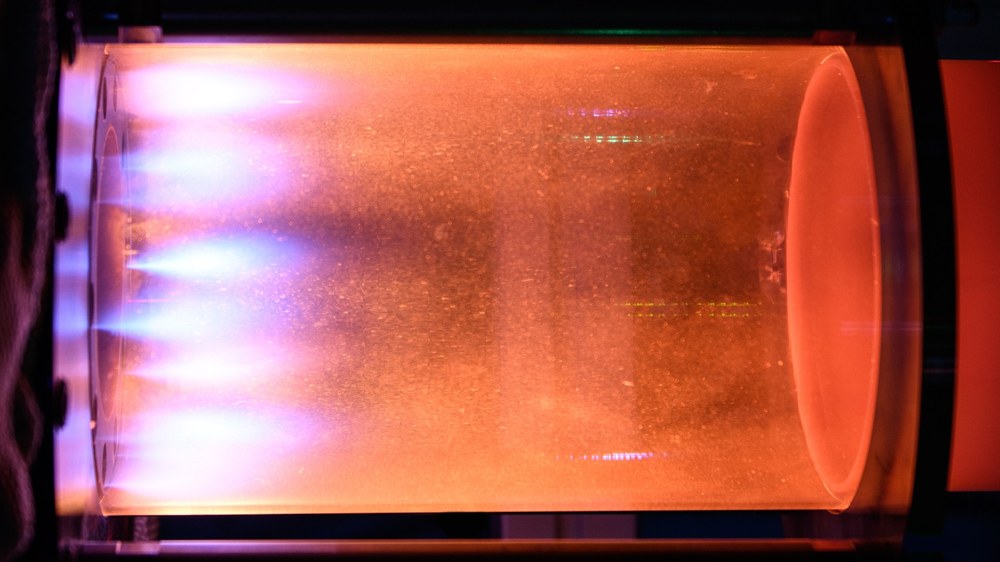

The retrofit team conducted the first test runs of the micro gas turbine using pure hydrogen in the H2-Container Technical Center at the DLR site in Lampoldshausen. "We were eager to see how the turbine would perform with the new combustion chamber system outside the laboratory environment," says Martina Hohloch. "The tests have shown that we can start up with pure hydrogen without any problems and that the system achieves the full operating range from partial to full load. Our pilot plant delivered its full electrical 100-kilowatt output for several hours." The system has now been operating on pure hydrogen for almost 100 hours.

The H2-Container Technical Center is an ideal test environment for the retrofit plant. It features two electrolysers that produce green hydrogen using electricity from the neighbouring Harthäuser Wald wind farm, operated by ZEAG Energie AG. The plant offers optimal conditions for companies and researchers. DLR in Lampoldshausen has decades of experience in handling highly reactive hydrogen and oxygen with its numerous engine test stands for space propulsion systems.

Flexible fuel selection

Another advantage of the retrofit concept is the high fuel flexibility of the turbines. Until sufficient green hydrogen is available, power plants must be operated with mixtures of natural gas and hydrogen. The gas turbines should run efficiently with all mixing ratios. However, the different combustion characteristics are a challenge. Power Service Consulting has therefore designed a flexible mixing and distribution system that adjusts the micro gas turbine to the respective fuel mixture. This allows the plant to be operated with both pure hydrogen and natural gas mixtures. To do this, adjustments in the control system and safety technology were required.

In the pilot plant in Lampoldshausen, the research team trialled the converted micro gas turbine in long-term tests. The goal of burning hydrogen and all mixtures with the lowest possible emissions was achieved.

As air consists of 78 percent nitrogen and 21 percent oxygen, the combustion of hydrogen with air also produces undesirable nitrogen oxides due to the high combustion temperatures of hydrogen. "The proportion of nitrogen oxides was less than 15 parts per million (ppm) over the entire operating range of the microturbine. This is significantly lower than the limit value for natural gas," emphasises Martina Hohloch. "This outstanding result confirms that jet-stabilised combustion is very suitable for hydrogen."

Micro gas turbines for decentralised power plants

Micro gas turbines are already being used in combined heat and power generation. They supply electricity where there is also a high demand for heat, for example in hotels, swimming pools or hospitals. The technology is particularly suitable for areas where the supply of renewable energies will become more complex in the future.

The fuel flexibility of gas turbines offers an additional business advantage. In industrial processes, wherever suitable gases are produced as a waste product, such as in sewage treatment plants or landfill sites, these gases can be used as fuel for the energy supply.

Together with storage systems, decentralised energy systems can be set up that are highly resilient to an overall failure. These energy systems range in size from a few kilowatts on a building scale to several dozen megawatts for urban neighbourhoods or small communities.

A new concept for gas turbines – a 'jet' stabilises combustion

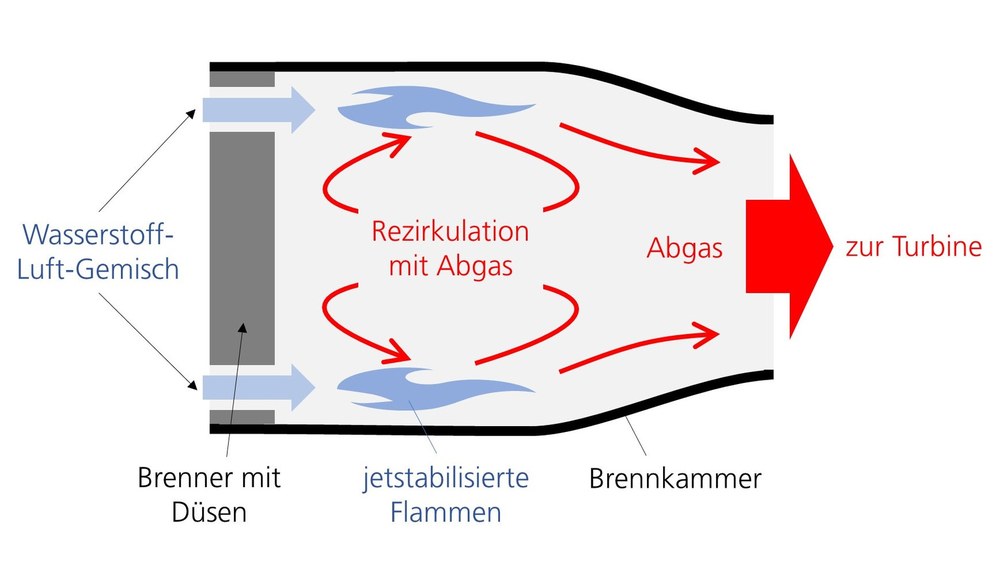

With highly reactive fuels such as hydrogen, there is a risk of flames flashing back from the combustion chamber into the burner, and destroying components. For this reason, the DLR Institute of Combustion Technology has developed a jet-stabilised burner optimised for hydrogen.

Unlike in conventional industrial burners, fuel and air are injected into the combustion chamber through nozzles arranged in a ring. This creates a backflow in the combustion chamber, transporting the hot exhaust gases back to the burner nozzles and mixing them with a fresh fuel mixture. This lowers the temperature in the combustion chamber and produces fewer nitrogen oxides. The recirculation of the exhaust gases also stabilises the flame very effectively. The concept is scalable and suitable for other turbine types and sizes.

Related links

- The Retrofit H2 project

- DLR Institute of Combustion Technology

- Clean power (Article from DLRmagazine 176)

- DLR's Research topic – Flexible jet-stabilised combustion chambers

- Green technology (Infographic in DLRmagazine 176)

- Power Service Consulting (PSC) GmbH

- Ansaldo Green Tech SpA

- Windpark Hardthäuser Wald der ZEAG Energie AG (German only)

- Baden-Württemberg Ministry of the Environment, Climate and Energy Sector

- Featured topic – Hydrogen – the energy source of the future

About the Retrofit H2 project

In the Retrofit H2 research project, the DLR Institute of Combustion Technology and the company Power Service Consulting (PSC) jointly analysed several retrofit concepts for existing power plants. The aim of the three-year project, which has just been completed, was to analyse energy technology pathways for hydrogen utilisation.

The Baden-Württemberg Ministry of the Environment, Climate Protection and Energy Sector supported the project with more than 900,000 euros as part of the ZPH2 Zukunftsprogramm Wasserstoff (Future Hydrogen) funding programme.