DLR agrees cooperation with Spanish start-up Pangea Aerospace

Pangea Aerospace

- DLR is addressing the growing demand for engine tests involving new, innovative space propulsion technologies.

- DLR and Spanish start-up Pangea Aerospace have agreed to collaborate, with a focus on testing a technology demonstrator of an additively manufactured aerospike engine from October 2021 onwards.

- At its Lampoldshausen site, DLR operates Europe's unique test infrastructure for space propulsion systems of all types and sizes.

- Focus: Space, engine technologies, microlaunchers

The German Federal Government is turning to efficient start-ups in its quest to ensure independent and competitive access to space for Europe. With their ideas and vision, they can accelerate the development of new technologies in the launcher market. To further that goal, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) Lampoldshausen site signed an agreement with the Spanish start-up Pangea Aerospace this summer 2021.

"By testing a new space propulsion system on behalf of the Spanish start-up Pangea Aerospace, DLR is using the expertise at its Lampoldshausen site to assist and support the development of future European launcher systems," explains Karsten Lemmer, Member of the DLR Executive Board for Innovation, Transfer and Research Infrastructure. "The cooperation with Pangea Aerospace is a first for us at the European level, and I am particularly pleased about it."

Their common aim is to test several aerospike engine, an innovative engine concept which can improve rocket engine efficiency by 15 percent. For this purpose, hot-fire tests will be carried out from October 2021 using several technology demonstrators developed by Pangea Aerospace and installed on the European research and technology test stand P8. Hot-run tests are comprehensive functional tests. They are an important step in the run-up to a first flight. The P8 test stand is one of DLR’s large-scale facilities and is unique within Europe. Among other things, it enables development tests to be carried out with smaller engines or components.

Pioneering new approaches to engine design

"By working together with start-ups, we can make the next launcher generation more efficient and competitive. The microlauncher segment is particularly interesting in this regard. These are small launch vehicles carrying payloads of a few hundred kilograms into low-Earth orbit. Innovative propulsion technologies are often used here. At DLR Lampoldshausen, we are ideally positioned to test these," says Stefan Schlechtriem, Director of the DLR Institute of Space Propulsion.

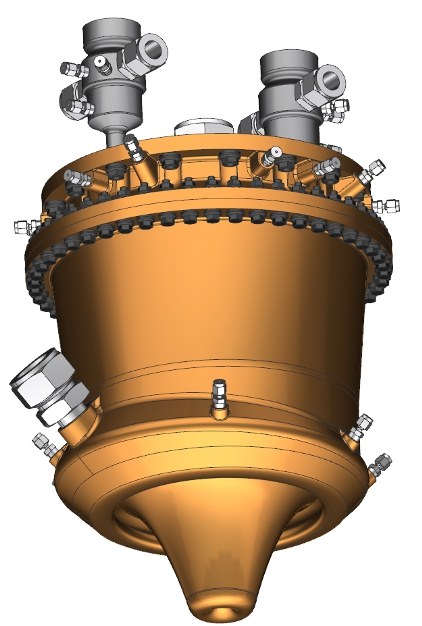

"The space industry is drastically being transformed and new solutions are sought to be more competitive. The aerospike engine has been considered as a most promising solution in rocket propulsion for decades, but it is only now that this technology can be built and engineered, thanks to new materials, and the design freedom that additive manufacturing provides. It is great to be working with DLR and to be able to fire the first copper additively manufactured aerospike engine in the world," says Adrià Argemi, CEO of Pangea Aerospace. The two-stage 'MESO' rocket, which is expected to carry up to 150 kilograms of payload into low-Earth orbit, has such an aerospike engine with a nozzle in the shape of a spike. It can therefore adapt much more flexibly to different flight altitudes. Thanks to higher efficiency, reusability as well as low costs and rapid manufacturing, this engine design can transform space propulsion significantly. To do this, the start-up relies on the latest metallic 3-D printing techniques and materials. Actually Pangea Aerospace has the exclusive capabilities in Europe for a new material called GRCop42, a powder copper alloy optimised by NASA for additive manufacturing of rocket engine combustion chambers. Liquid oxygen and liquid methane are used as propellants.

DLR expertise and flexible test systems for competitive launchers

The global space market is more dynamic and diverse than ever. In addition to the European Ariane launcher, microlaunchers are increasingly expanding the range of launch options for loads of different masses. Microlaunchers often emerge from young companies and have a much shorter development time. With its extensive expertise and flexible test infrastructure, DLR is ready to support these processes. As a European research and test centre for liquid-fuelled engines, it has the ideal conditions and flexible systems. "Our test facilities already cover the entire portfolio of tests on engines of all types and sizes. They are available to small and medium-sized enterprises and start-ups," says Schlechtriem, adding: "With every test on one of our test stands, we gain valuable new knowledge together. This in turn flows into the development of new engines. This makes us a unique and valuable partner for institutional and private spacetransport."