Five and a half minutes of microgravity for experiments

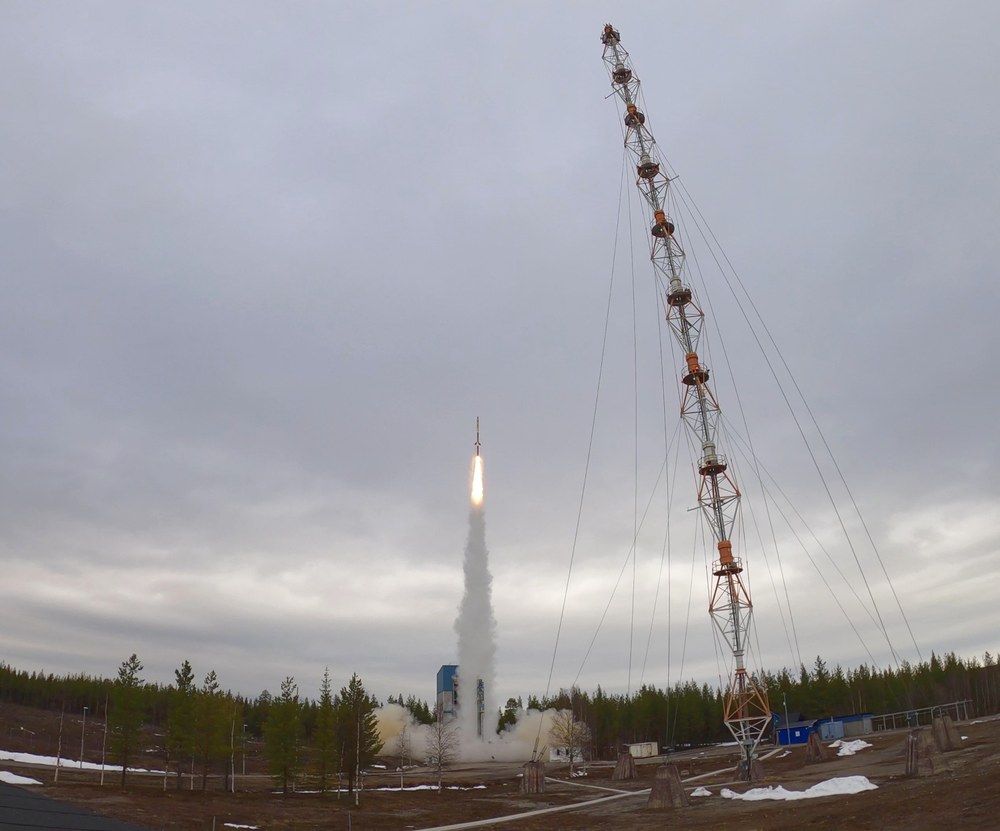

- DLR's MAPHEUS 11 sounding rocket successfully launched at 07:35 CEST on 24 May and reached an altitude of 221 kilometres.

- On board were the materials science experiments MARS, X-RISE and SOMEX.

- Among other things, a powder-based 3D printing process was successfully tested in microgravity.

- Focus: Spaceflight

On 24 May 2021, three experiments from the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) set off on their short journey into microgravity and back again. The DLR sounding rocket MAPHEUS 11 lifted off from the Esrange Space Center in northern Sweden and carried the materials science experiments MARS, X-RISE and SOMEX to an altitude of 221 kilometres. In the 15 minutes between launch and landing, the payloads followed a parabolic path after the propulsion systems were jettisoned. This allowed five and a half minutes of microgravity to carry out the experiments. After the flight, the experiments were recovered by helicopter. On the ground, a team from the DLR Institute of Materials Physics in Space followed the action with their 'fingers crossed'. After all, in addition to the acquisition of scientific knowledge, there is much passion invested in each of the three experiments.

MARS – how does metal-based 3D printing work in space?

In 3D printing – also referred to as additive manufacturing – powdered material is applied layer by layer until a three-dimensional component is created. In contrast to conventional processes, in which a component is milled out of a block, 3D printing has several advantages. It is flexible and fast, very complex shapes can be created and there is little material waste. "These advantages also make additive manufacturing processes interesting for space applications in reduced gravity, for example on the Moon or Mars, or in microgravity during a space flight," explains Andreas Meyer, Head of the DLR Institute of Materials Physics in Space. The few minutes of experimentation time during the flight were enough to print a first small component.

"The MARS experiment is a first in this field. We are laying the foundations so that space missions can produce larger parts later. The structures required by future missions may be manufactured on site in space, such as on orbital platforms, which would considerably reduce the transport effort from Earth to space," Meyer explains. The 'Metal-based Additive Manufacturing for Space and Microgravity Applications' (MARS) experiment focuses on special metal alloys. They can be used to produce components with very advantageous properties. These include, above all, very high strength and corrosion resistance. For the flight on MAPHEUS 11, the DLR Institute developed a compact rocket payload based on a new process developed by the German Federal Institute for Materials Research and Testing (Bundesanstalt für Materialforschung und -prüfung; BAM). The payload carried out the additive manufacturing process fully automatically in microgravity during the flight.

X-RISE – better understanding diffusion in liquid metal alloys

Using the X-Ray Investigation in Space Environment (X-RISE) experiment, DLR researchers want to understand the fundamental processes of atomic transport and diffusion in metallic liquids. Two miniaturised (shear-cell) furnaces melted aluminium-germanium and aluminium-indium alloys for this purpose. A special X-ray system then acquired images in real time during the diffusion process. With the help of these images, the scientists will be able study the movement of the atoms in the liquid metals.

"Diffusion is an important parameter for many processes in materials science, including the examination of material structures. On Earth, gravity-driven flows often interfere with experiments on diffusion. In microgravity, on the other hand, we get a more accurate picture of the processes," explains Meyer. The X-RISE experiment was in operation for the fifth time on MAPHEUS 11.

Previous experiments have investigated, among other things, the solidification behaviour of metallic alloys, microstructure formation and the dendritic growth of crystal structures in aluminium-germanium alloys. "With experiments in X-RISE, we can understand diffusion in liquids, confirm models for the solidification of alloys and verify the results of our laboratory experiments on Earth." Meyer summarises. Among other things, these results can help to optimise industrial casting processes.

SOMEX – universal light scattering laboratory for the study of soft matter

With the SOft Matter EXperiments (SOMEX) instrument, the DLR Institute of Materials Physics in Space has developed a universal platform for studying soft matter in microgravity. Soft matter is understood to be two phase systems that are between the physical states of solid and liquid. With SOMEX, the DLR team has succeeded for the first time in realising an experimental setup that, despite its small volume, offers plenty of space and the possibility to study experiments using a large range of optical methods. The SOMEX module is pressure-tight and designed for several flights into space. In addition, the samples, some of which are very sensitive, can be easily integrated into the module until shortly before launch using the specially designed quick-release fastener.

Static and dynamic light scattering, as well as differential dynamic microscopy, were used in flight for the first time on MAPHEUS 11. An epifluorescence microscope is under development. This will open up a wide range of applications for SOMEX.

On the successful first SOMEX flight, experiments were carried out to gain a fundamental understanding of the scattering physics of granular matter. In addition, the dynamics in a model system for self-propelled micro-floats were investigated. "In the Earth laboratory, buoyancy and sedimentation effects strongly distort the results. Compared with theoretical predictions, the SOMEX experiments enable new insights into the structure and dynamics of such systems in both cases," Andreas Meyer is pleased to report.

About MAPHEUS

The MAPHEUS (Materialforschung unter Schwerelosigkeit; material physics experiments under microgravity) high-altitude research programme has been operating for 12 years. The annual flights, prepared and carried out by DLR's Mobile Rocket Base (MORABA), give scientists independent and regular access to experiments in microgravity. In this programme, advances in measurement technology and the realisation of sophisticated flight hardware go hand in hand with cutting-edge experiments, for example in the field of materials and life sciences.