Research for environment-friendly production plants

- Industrial processes will be redesigned to generate less carbon dioxide.

- The Institute's High-Performance Heat Pump research facility efficiently generates the high temperature heat required in industrial process.

- The Institute will contribute to structural change in the region.

- Focus: Energy, sustainability, hydrogen

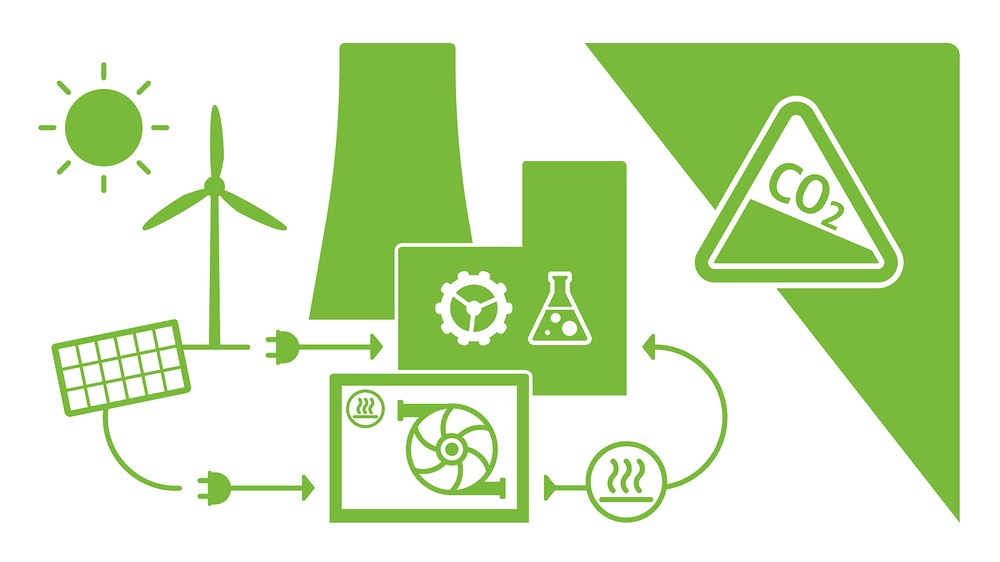

How can industrial processes be designed to generate fewer harmful greenhouse gases and how can existing plants be adapted to take on the challenges of decarbonisation? These are the research focuses of the new Institute of Low-Carbon Industrial Processes at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR). DLR’s Zittau site, the home of the new institute, was officially inaugurated on 10 March 2021 with an online event. In addition to this site in Saxony, the Institute will also be based at another site, which is currently being established in Cottbus, Brandenburg.

"With its scientific research, our new institute in Zittau will help Germany to achieve its national climate targets. Decarbonising energy-intensive processes will prevent emissions on a large scale," explains Anke Kaysser-Pyzalla, Chair of the DLR Executive Board. "Our employees are motivated by the scientific challenge of transforming industrial processes ecologically and cost-effectively. This involves finding solutions that take regional characteristics and existing structures into account."

DLR is thus expanding its expertise in the field of energy research in the region of Lusatia. The aim is to significantly reduce carbon dioxide and pollutant emissions from industrial plants and power plants. The work focuses on decarbonisation in industrial sectors with a high energy demand. Simultaneously, there is a focus on the efficient use and storage of sustainably generated electricity.

"Saxony was, is and should continue to be an industrial state, but without polluting the environment," explains Michael Kretschmer, Minister President of Saxony. "With its research and innovative spirit, the new DLR Institute of Low-Carbon Industrial Processes in Zittau will significantly contribute to this goal. Low-carbon processes help with the gradual transition to environmentally friendly and climate-neutral industrial production. Thanks to the close cooperation between science, industry and government, the Free State of Saxony is able to provide significant drive on the road to achieving a decarbonised economy and energy system.”

Cooperation with universities and industry

The DLR Institute of Low-Carbon Industrial Processes will support the development of new technologies by regional academia and industry. This facilitates an active contribution to structural change in the region and to job creation. Intensive cooperation with the universities of Zittau/Görlitz and Cottbus-Senftenberg is already underway, as is cooperation with local industrial companies. This enables an effective transfer of knowledge from fundamental research to applications for industrial use.

"As Commissioner for the new Federal States, I am pleased that the DLR Institute, with its two sites in Zittau and Cottbus, will make a significant contribution to the path to low-carbon industries of the future," says Marco Wanderwitz, Parliamentary State Secretary at the German Federal Ministry for Economic Affairs and Energy. "Low-carbon industrial processes, as part of the industrial strategy of the Federal Minister for Economic Affairs and Energy, are important for the future of industry in the new and old federal states. They enable positive structural change in the region, especially in the new federal states, where industry is still the key driver of economic development today."

It is expected that 60 personnel will eventually be employed at the Zittau site. Since the DLR Senate officially founded the institute in June 2019, its staff have been operating on the premises of the Zittau/Görlitz University of Applied Sciences and are expected to move to the Mandauhöfe in Zittau in June. A hall has also been rented for the establishment of one of the research facilities. Over the next few years, a new building with a large hall for experiments will be constructed for the institute near the Zittau University Library.

"The opening of the DLR Institute of Low-Carbon Industrial Processes at the institute's Zittau branch has come at the right time," explains Martin Dulig, Saxony's State Minister for Economic Affairs, Labour and Transport. "Climate-friendly industrial processes are a global concern. Climate-neutral living and working is a wonderful vision. This institute will provide significant impetus for this with excellent research as well as economical and at the same time ecological innovations. Its impact will extend far beyond Lusatia and Saxony. DLR, the federal government and Saxony are establishing a lighthouse in Zittau with international appeal. Companies in Saxony in particular are being called upon to conduct joint research with the new DLR institute. Such research can provide them with a valuable advantage in adopting pioneering technologies."

Using steam and hydrogen produced from renewable sources

Research in Zittau is conducted primarily via the departments of 'High-temperature Heat Pump' and 'Low Carbon Reducing Agents'. The institute’s third focal area, 'Simulation and Virtual Design', is located at the Cottbus site. The developments on new types of high-performance heat pumps focus on the provision of carbon-neutral, high-temperature heat for industrial processes. The large industrial demand for this heat is currently met primarily using fossil fuels. High-temperature process heat is indispensable in the food industry, the paper industry, the chemical industry and in vehicle construction. The challenge lies in the efficient generation of heat using electricity produced from renewable sources. The research facility in Zittau, for example, operates using steam.

Hydrogen plays a central role in the 'Low-Carbon Reducing Agents' research area. This involves investigating how processes can be adapted to prevent process-related carbon emissions. This could be achieved using hydrogen produced from renewable sources or, in part, waste biomass.