Robot ballet in record time: a world first – lightweight wings manufactured using two synchronised robots

- DLR and partners demonstrate time-saving in CFRP aircraft manufacturing using two robots working in parallel.

- Improved hardening process further reduces production time.

- Focus: aviation, Industry 4.0

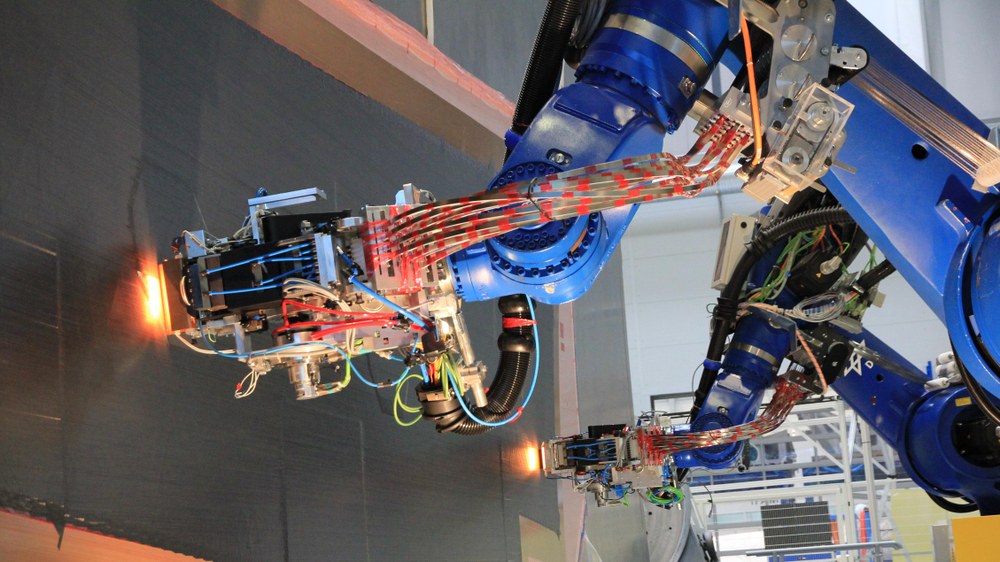

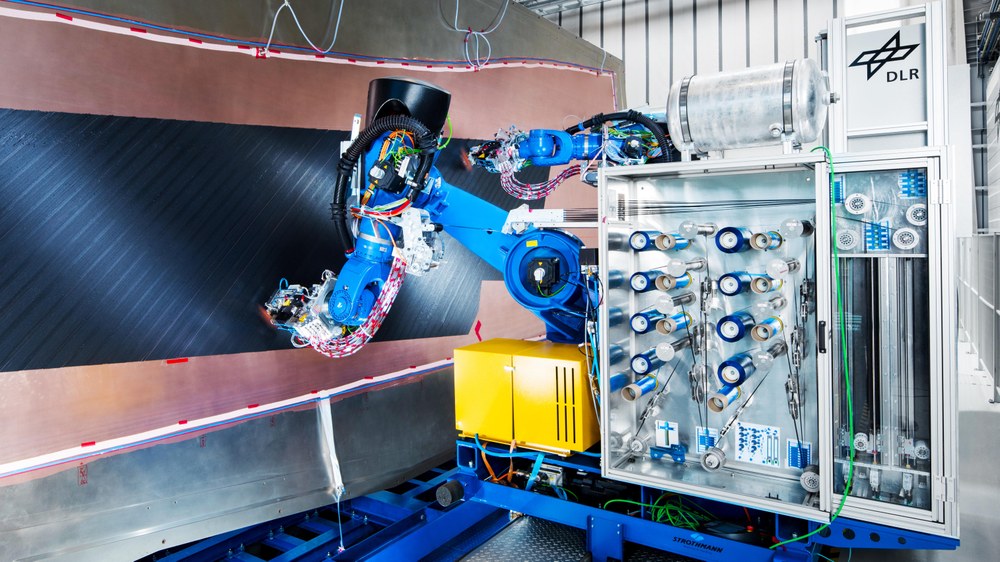

Lightweight and therefore kerosene-saving wings made from carbon fibre reinforced plastic (CFRP) are already being used in the quiet, fuel-efficient flagship Airbus A350. But production has been extremely expensive and time-consuming thus far, because only one robotic laying unit stacks carbon fibres layer by layer, until a wing shell is formed. Even in three-shift operation, this takes up to seven days and slows down a new aircraft's entire production process. Scientists at the Center for Lightweight-Production-Technology (ZLP) at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) in Stade have now demonstrated how two robots working in parallel without colliding can halve the production time.

"Together with our partners, Airbus/CTC, Fraunhofer IFAM and Fibretech Composites, we have successfully demonstrated the next major milestone in the efficient wing shell manufacturing of tomorrow. For the first time, DLR was able to use a process whereby two robotic units on the same rail with overlapping operating zones simultaneously lay fibres on a wing shell tool," says Jan Stüve, Head of the Composite Process Technology Department at the DLR Institute of Composite Structures and Adaptive Systems. "At the first attempt, this resulted in a time-saving of 38 percent and there is room for further improvement."

Model wing with all the features

For the test run of the joint EWiMa project (Efficient Wing Cover Manufacturing), researchers designed a model of a complete wing shell with an area of 15 square metres and a span of eight metres, which includes all the features of a future CFRP wing for short and medium-haul aircraft. A finished wing is ultimately composed of an upper and lower shell.

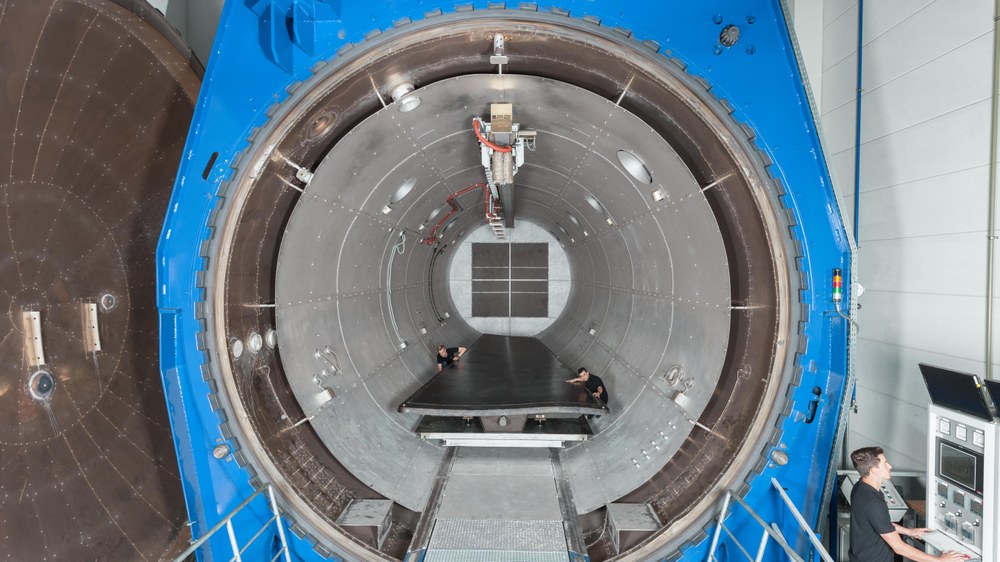

Faster, targeted hardening

After the fibre layers have been applied, a CFRP wing then has to be laboriously hardened in a large autoclave at high pressure and high temperature. "Within the framework of the project we also found a way to further reduce the production time by looking at this second stage of the process," says Delisle, explaining: "Instead of only heating the wing shell in the autoclave from above, we also heated the moulding tool located below the wing shell." This technique makes it possible for the wing shell to be hardened in an extremely targeted manner, depending on the thickness.

Research for the factory of the future

The development of innovative production technologies and systems concepts to produce multi-material lightweight construction applications in the future is one of the core areas of activity of the Institute of Composite Structures and Adaptive Systems, which includes the EWiM project funded by the Federal Ministry for Economic Affairs and Energy as part of the German Federal Government's Aviation Research Programme. The foundations for a research platform for Future Factory 2030 for multi-material lightweight construction were laid in 2010 with the opening of the Center for Lightweight-Production-Technology in Stade. In Future Factory 2030, machines and installation components are networked, mobile robotic units operate autonomously, artificial intelligence decides on production sequences and component defects are assessed during the production process and automatically corrected if necessary. The 'Future Factory 2030' research field is the systematic implementation of the DLR Strategy 2030 and supports the DLR interdisciplinary project, 'Factory of the Future'.