DLR at the Hannover Messe: Alternative fuels, low-emission gas turbines and air conditioning for electric cars

Carbon dioxide-neutral fuels are an important next step on the road to climate-friendly energy supply. Energy researchers from the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) will present how this kind of energy source can be manufactured and exploited in future, especially using solar power, at the Hannover Messe from 24 to 28 April 2017. With its exhibits of the HY4 fuel cell aircraft and an air conditioning system for electric vehicles, DLR is showcasing clear examples of how sustainability can be implemented within mobility as well. Moreover, DLR will introduce a modern gas turbine with low pollutant emissions, designed for decentralised energy supply. From the field of robotics, DLR will present an airbag designed to ensure safe human/machine interaction.

"To ensure climate-friendly energy supply, we need solutions for the transport and heat sector beyond the energy sector," says Karsten Lemmer, DLR Executive Board Member for Energy and Transportation. "Our research on alternative drive systems, renewable fuels and sustainable storage facilities allows us to devise innovative solutions for an efficient energy system. We will thus be able to make the transport sector – which accounts for just under 20 percent of carbon dioxide emissions in Germany – more sustainable in the medium term. Projects such as the Hy4 fuel cell aircraft benefit from the close connections between DLR's energy and transport research and the significant interdisciplinary expertise this yields." DLR will present some of its energy research at the Hannover Messe 2017 in Hall 27, Stand G68, and at the Hydrogen Fuel Cells Joint Stand, D66, also in Hall 27. In addition, DLR will showcase a robotic arm with airbag at KUKA AG’s Stand G04 in Hall 17.

The world's largest artificial Sun

The Synlight research facility at the DLR site in Jülich incorporates 149 light sources, each with the output of a large cinema projector, making it the largest artificial Sun in the world. Together, these sources generate a light flux corresponding to nearly 100,000 bulbs of 60W and an inten¬sity 10,000 times the natural solar radiation. Researchers can use the artificial Sun to carry out experiments under reproducible conditions and regardless of weather conditions, thus driving forward new developments like solar fuels or solar power plant components. Ageing tests under high UV light as well as applications for extreme temperatures will also be possible. Engineers at the DLR Institute of Solar Research designed the system, which was inaugurated in March 2017, and are available to assist partners as the experiments are performed. At the trade fair, DLR will showcase a one-metre diameter lamp, as well as provide a virtual reality tour through the 15-metre Synlight facility.

Hydrogen from water and sunlight

Hydrogen is not a primary energy source; this energy carrier must first be generated using other energy sources. In relation to its mass, hydrogen contains more energy than any other chemical fuel; when it is combusted, only water and heat are generated. In turn, solar energy is by far the most abundant source of energy on Earth. In the HYDROSOL_PLANT project, researchers at the DLR Institute of Solar Research have developed a production process with which they can generate hydrogen directly from water using sunlight. Using a solar chemical reactor, thermal energy from the Sun is used directly for hydrogen generation via a redox reaction. In 2017, researchers are testing a 750-kilowatt reactor at the Plataforma Solar de Almería, operated by the Spanish research centre CIEMAT. The reactor is a further development of a system successfully used by researchers for thermo-chemical hydrogen generation in 2006. This innovation was awarded the European Commission’s Descartes Prize.

Innovative air conditioning unit for electric vehicles

The DLR Institutes of Engineering Thermodynamics and To the Institute's website are developing innovative auxiliary units for air conditioning electric vehicles as part of the DLR Next Generation Car (NGC) project. With fuel cell vehicles, this assembly consists of two reactors – each the size of a small shoebox – that are filled with metal hydrides. The air conditioning unit is an open system that can be incorporated into the existing hydrogen infrastructure of the fuel cell drive train without consuming hydrogen. The pressure difference between the hydrogen tank, which stores the gas at several hundred bar, and the fuel cell, which is fed at five bar, is used to start the reaction process. The air conditioning unit can also be extended for use in battery-driven electric vehicles as a closed system without affecting the range of the vehicle. To do so, two further reactors are required that act in the same way as the hydrogen tank. A unit for electric vehicles in the 2.5-kilowatt range has already been developed and will be field-tested with industrial partners. A prototype at the DLR stand demonstrates how the air conditioning system works.

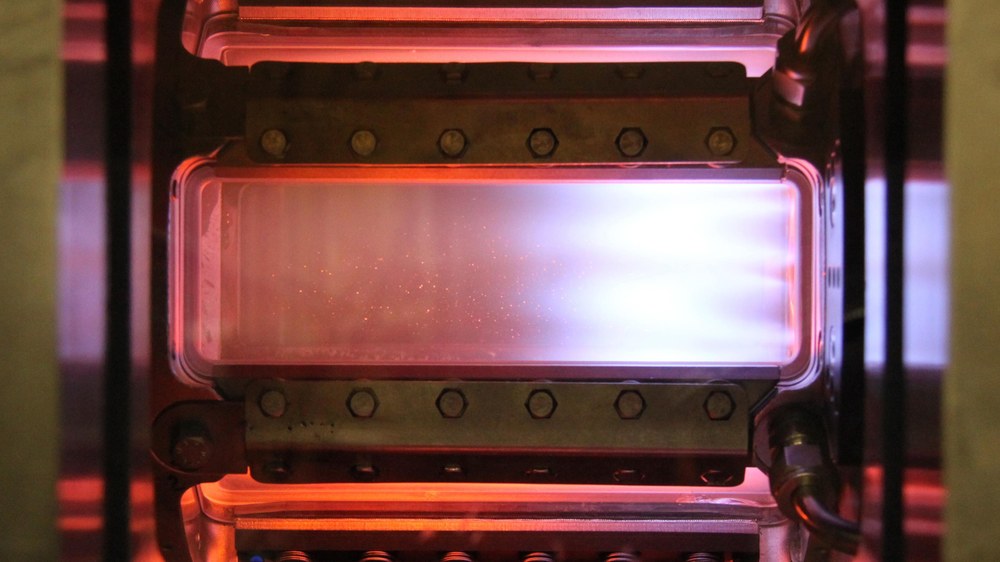

Gas turbine with low pollutant emissions

Modern combustion chambers for gas turbines have to meet many requirements: they must always operate optimally under different loads, be suitable for burning many different fuels, from methane gas to wood gas, and they must also emit as little pollutants as possible under all operating conditions. The FLOX® Burners for Gas Turbines (FLameless OXidation) combustor meets these requirements and thus offers a promising alternative, especially for decentralised energy supply units, for instance in residential complexes. The exhibit presented by the DLR Institute of Combustion Technology shows two FLOX® combustors for use in micro-gas turbines. The larger combustor is designed for systems with an electrical power output in the 100-kilowatt range and the use of wood gas as fuel. Wood gas is produced during the thermochemical gasification of woody biomass and is therefore particularly suitable as a product gas for the operation of decentralised combined heat and power plants. Due to its composition, it is difficult to use in conventional internal combustion engines. The smaller burner is designed for systems with an electrical power output in the three-kilowatt range; it can use biogas with a low calorific value. The air inlet temperature for this combustor is in excess of 700 degrees Celsius. The combustion chamber is already fitted to a demonstration system in Vaihingen/Enz, where it uses the accumulated biomass from a landscape conservation business, while also supporting the production of district heating at a cogeneration plant in Leonberg in cooperation with EnBW and Dürr Systems GmbH.

Flying with fuel cells

The Hy4 is the world's first four-seat passenger aircraft powered solely by a hydrogen fuel cell and battery system. The maiden flight of the aircraft, which has a range of up to 1500 kilometres, took place on 29 September 2016. The HY4's power train consists of a hydrogen storage unit, a low-temperature hydrogen fuel cell and a high-performance battery. The fuel cell converts the energy of the hydrogen fuel directly into electrical power. The only waste product from the process is water. The electric motor uses the generated power to propel the aircraft. The lithium-ion battery installed on board provides additional power during the take-off phase and when climbing. The fuel cell aircraft was developed by the DLR Institute of Engineering Thermodynamics together with partners Hydrogenics, Pipistrel, H2Fly, Ulm University and Stuttgart Airport, and is operated by H2FLY. Visitors to the DLR stand will find a 1:4 scale model of the aircraft, as well as information on the operation of the powertrain.

Electrolysis for a hydrogen rocket

In addition to the direct production of hydrogen from sunlight, the energy carrier is currently generally produced by electrolysis – the process by which water is decomposed into hydrogen and oxygen using electricity. Hydrogen, generated in large quantities by excess wind power, is a possible energy storage system for the future. The processes behind this are being optimised in projects such as H2ORIZON at the DLR facility in Lampoldshausen. The hydrogen rocket exhibit allows visitors to generate this electricity themselves using a hand crank. The electrolytic reaction takes place in a container filled with water in which two elec¬trodes are powered by direct current. If sufficient gas (hydrogen and oxygen) is collected under the rocket, it is ignited and reacts to once again form water. The energy released in the oxygen-hydrogen reaction propels the rocket upwards.

Research on batteries, fuel cells and electrolysis

The DLR Institute of Engineering Thermodynamics will present the findings of its research into batteries, fuel cells and electrolysis at the Hydrogen Fuel Cells Joint Stand (D66, also in Hall 27). An information terminal shaped like a battery will provide details of the battery activities at DLR. Electromobility can only be achieved if batteries become more efficient, more economical and affordable. The research mainly seeks to characterise batteries in the lithium-ion group and to investigate promising battery materials such as lithium-sulphur, lithium-air, zinc-air and magnesium-sulphur. The exhibit, which showcases research into fuel cell technology, gives an overview of the possibilities of storing energy using the examples of a solid oxide fuel cell (SOFC), a solid oxide electrolysis cell (SOEC), power-to-X and a hybrid power plant (SOFC/gas turbine). It also presents the underlying principles, the various applications and their electric efficiencies, also in comparison to standard power plant technology. Research projects on PEM electrolysis (polymer electrolyte membrane), a promising technology used to produce sustainable hydrogen in a future energy and transportation system, will also be presented. DLR's research focuses on the development, integration and characterisation of efficient and affordable materials or components, such as highly efficient catalysts, cost-effective electricity collectors, as well as the substitution of titanium using corrosion protection coating for bipolar stainless steel plates.

Robotic airbag for safe human/machine interaction

Production processes are bringing robots ever closer together. But sharp-edged robotic tools and work pieces make this form of collaboration a particularly dangerous affair. To solve this problem, scientists from the DLR Robotics and Mechatronics Center have developed an airbag that allows humans and robots to work together without limiting the robotic system's overall functions. Like in a car airbag, the system fills up with compressed air, enclosing the robot tool and work piece before every movement. The system deflates the airbags, releasing both pieces, whenever the arm comes to rest. This enables shorter clocking of production processes and an increase in productivity. The robotic airbag is one of five finalists in the KUKA Innovation Awards 2017. It will be on show at the robot manufacturer's Stand G04 in Hall 17. An international jury of scientists will select the award winner and announce the results on 27 April 2017.

DLR Technology Marketing

DLR Technology Marketing forms the interface between research and industry. Its task is to handle cross-sector transfers of DLR technologies and foster contacts with innovative enterprises of any size. It works in concert with DLR institutes and includes industrial partners at the earliest possible time to turn research findings into usable technologies. In addition, DLR Technology Marketing investigates markets and trends, develops innovative ideas, secures competitive advantages through property rights, concludes agreements on the commercial exploitation of DLR technologies, and provides assistance with the setting up of DLR spin-offs.