Economical, efficient, sustainable – thermochemical storage 'reloaded'

Energy researchers at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) have put into service an innovative thermal storage system that uses lime as the storage medium. The lime storage system is a further development of an initial prototype and can store energy more economically and efficiently. Thermochemical storage systems have the potential to save a considerable amount of energy, especially in industrial processes and households.

Storage system increases heating sector efficiency

While the electricity sector has already moved strongly towards a sustainable supply, the energy transition is moving very slowly in the heating sector, which accounts for more than half of the overall demand for energy. Storage systems offer great potential for using energy more efficiently, particularly in the industrial sector, thereby reducing consumption of fossil fuels. Using lime as a storage medium, the DLR researchers have developed a concept usable in processes with high temperatures.

When heated, the storage medium (slaked lime) begins an endothermic reaction that starts at approximately 450 degrees Celsius and creates calcium oxide. Roughly 20 percent of the input is stored in the form of sensible energy and the rest as chemical energy. Depending on the insulation, the sensible energy can slowly be lost over a prolonged period of time, but the chemical energy is storable for an unlimited amount of time and is released only when needed. For this purpose, steam is fed in to cause a strongly exothermic reaction that releases the heat again.

Lime is an ideal medium for long-term storage

As this chemical reaction allows indefinite storage of much of the heat, the system is particularly suited to prolonged storage periods. The researchers also opted for lime as the storage medium because it is a very affordable material. In conjunction with the very high energy density brought about by the chemical reaction, it will be possible to create economical heat storage systems in the future.

Marc Linder, Research Area Manager for Thermochemical Systems at the DLR Institute of Engineering Thermodynamics in Stuttgart, said: "Storing heat thermochemically with lime is an interesting alternative to the more developed technologies in the fields of power plant technology and process heat. In addition to these fields of application, we see potential for lime storage in the seasonal storage of energy, for example, so as to support the supply of heat to households."

Versatile use thanks to temperature control

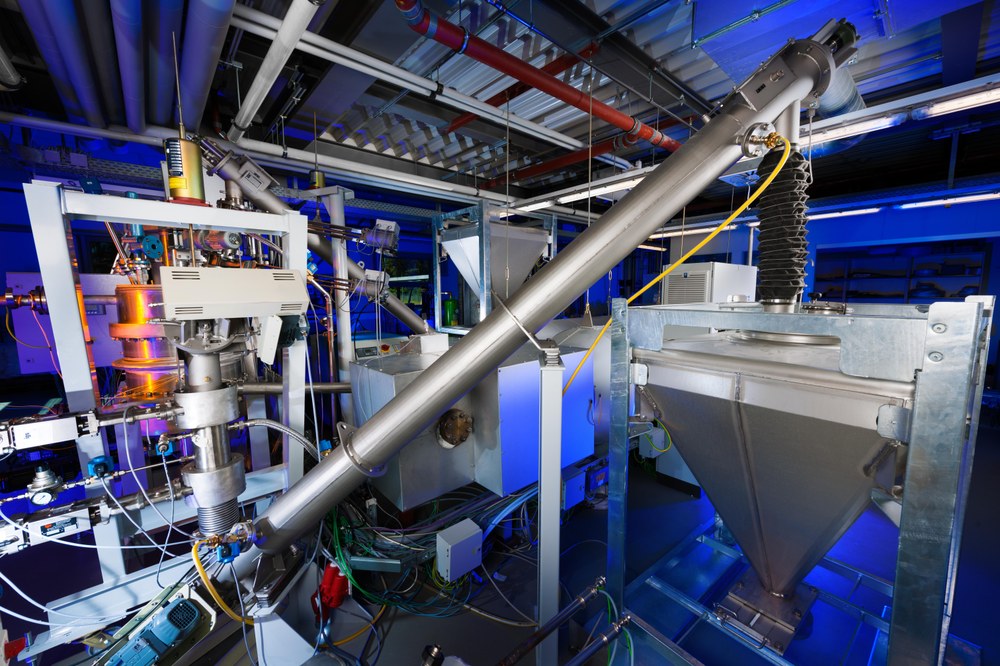

To store process heat, a reactor is used for heating and burning in a special heat exchanger in the plant. For this purpose, the researchers are now using a stainless steel tube through which the lime flows in the more advanced storage system. This enables the burning of any desired amount of lime in the plant. The resupply comes from silos installed at the beginning and end of the cycle. An additional advantage of chemical storage, which is now being examined at the plant, lies in the regulation of the temperature inside the storage system. With the new system it is possible to inject steam at differing high pressures into the burnt lime. If the steam pressure is increased, the reaction occurs at a higher temperature. If the pressure is decreased, the reaction temperature goes down.

"The challenge with the new lime storage facility is to optimise the interaction of continuous motion of the storage medium together with the supply of heat and the control of the steam," says Matthias Schmidt, Project Manager at DLR’s Institute of Engineering Thermodynamics.

Expert workshop on thermochemical energy storage

The German Federal Ministry for Economic Affairs and Energy (Bundesministerium für Wirtschaft und Energie; BMWi) commissioned the first test facility for energy storage. The current onward development of the reactor came about as part of a European research project that was coordinated by DLR and was recently completed successfully. At the same time, two other EU thermochemical energy projects are in progress in parallel with the TCS Power project. In September 2015, all the projects were brought together for a final meeting at DLR. Fifteen European research institutes and organisations presented and exchanged information about their current work and results with thermochemical heat storage. The workshop took place in the CeraStorE (CERAmics, STORage, Energy; Competence Centre for Ceramic Materials and Thermal Storage Technologies in Energy Research) facility. This storage competence centre was opened in 2013 and is part of the DLR site in Cologne-Porz. Scientists from the fields of materials research, solar energy research and thermodynamic engineering are working together on subjects related to energy storage and also have an opportunity to test processes at larger and more realistic scales in the CeraStorE laboratory.