SOMMER

Green chemicals derived from solar energy and CO2

Duration: 1.11.2023 - 31.10.2027

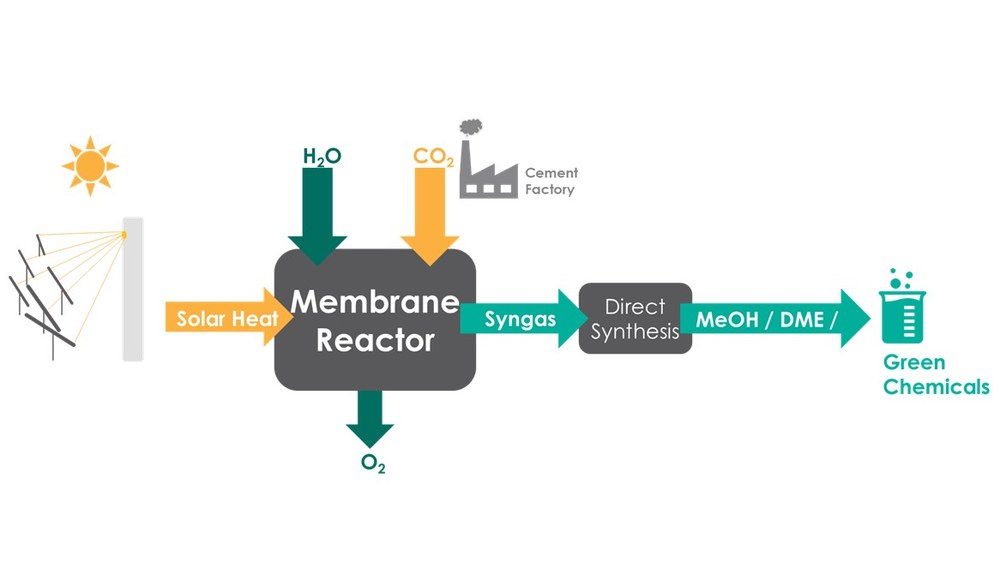

Synthesis gas (syngas) is a crucial feedstock in the chemical industry, composed primarily of hydrogen and carbon monoxide. It serves as the foundation for producing essential chemicals such as methanol and dimethyl ether, which are then used to manufacture plastics, fuels, and fertilisers.

The EU-funded project SOMMER is developing a sustainable method for syngas production by replacing fossil-based sources with solar-driven processes. Instead of relying on conventional resources, SOMMER leverages concentrated solar radiation to convert water and CO2 into syngas.

The CO2 is sourced from unavoidable process emissions, such as those from cement production or direct air capture. A novel catalytically active membrane enables the splitting of molecules without external electrical power, laying the groundwork for a climate-neutral chemical industry.

Development of an Innovative Solar Membrane Reactor

The core of the SOMMER project is a solar-powered membrane reactor that efficiently converts water and CO2 into syngas. The project experimentally explores different membrane and catalyst materials that must withstand extreme reaction temperatures of up to 1,500 degrees Celsius.

Forschungszentrum Jülich (FZJ), CSIC and hte GmbH are leading efforts to select the most effective catalytically active membranes, ensuring long-term efficiency and performance.

Advanced Membrane Manufacturing: Extrusion and 3D Printing

The membranes are manufactured using two advanced techniques: The first is extrusion, a process where material is shaped by being pressed through a defined opening. SOMMER collaborates with Haldenwanger GmbH, a globally recognized ceramic manufacturer, to apply this method.

The second technique involves 3D printing, employed by the Spanish research institute IREC to develop innovative membrane geometries that enhance reactor power density. These advanced manufacturing methods enable the production of highly specialized membranes that are both durable and efficient.

SOMMER

Industrial Collaboration and Material Testing

Before integrating the membranes into the solar reactor, they undergo rigorous testing by hte GmbH, a leading German company specializing in catalyst and material research. These tests ensure that only the most effective and resilient materials are selected for reactor implementation.

Testing at DLR’s High-Performance Solar Facility

The performance of the solar membrane reactor is being tested at the High-Flux Solar Simulator at the DLR Institute of Future Fuels in Cologne. Two operational scenarios are being experimentally demonstrated:

- Direct CO2 and Water Splitting: At 1,500 degrees Celsius, syngas is produced solely from water and CO2, with concentrated solar radiation supplying the necessary energy.

- Assisted Process with Sustainable Hydrocarbons: At 900 degrees Celsius, biogas is introduced to enhance efficiency and enable continuous operation by integrating thermal energy storage, ensuring functionality beyond daylight hours.

System Analysis and Industrial Integration

The CO2 required for the process can be sourced from unavoidable emissions in cement production. To evaluate the integration of SOMMER technology into industrial applications, the project team is conducting a comprehensive system analysis. This study examines the feasibility of coupling syngas production with cement manufacturing and methanol synthesis plants.

Additionally, a techno-economic, environmental, and life cycle analysis of the technology is being carried out by hte GmbH and DLR to determine the viability of large-scale implementation. A strategic roadmap outlines potential industrial applications and adoption strategies for sustainable syngas production.

Advancing Towards a Climate-Neutral Chemical Industry

The SOMMER project aims to bring the technology to Technology Readiness Level (TRL) 4, demonstrating a laboratory-scale prototype. With strong collaboration across key industry partners, including Titan Cement Company S.A., the project sets the stage for future scaling.

This innovation presents a significant opportunity for industries such as cement production — one of the largest global CO2 emitters — to transition towards a circular economy. At the same time, the SOMMER technology offers a sustainable solution that can help reduce the carbon footprint of the chemical industry. By introducing renewable syngas production, SOMMER contributes to the transformation of energy-intensive industries and supports the transition to a climate-friendly chemical value chain.

Further information can be found on the project website:

Project | SOMMER |

|---|---|

Duration | 1.11.2023 - 31.10.2027 |

Projectparticipants |

|

Funding | Funded by the European Union under grant agreement No 101118293. |