Institute of Low-Carbon Industrial Processes

The Institute of Low-Carbon Industrial Processes is augmenting DLR’s research portfolio through the new focal area of CO₂-reduction for industrial processes.

Duration: 1.1.2023 - 31.12.2026

Integrating renewable energies into industrial processes is a fundamental step towards reducing greenhouse gas emissions. This not only raises the question of how each individual process can be designed to achieve this goal, but also what possibilities there are for linking processes in order to utilise energy and material flows in a resource-saving manner. In this way, efficiency can be increased and waste volumes reduced. But what opportunities and challenges arise for innovative processes based on renewable energies?

DLR researchers want to answer these and related questions with their investigations in the SOLINT project. The focus is on mining, solar base and fuel production, photoelectrochemical fuel, electricity and heat generation and sustainable fertiliser production.

The capture of CO2 from the air and industrial emissions will play a key role in the transition to greenhouse gas-neutral industrial processes. This technological approach makes it possible to utilise CO2 as a raw material and thus operate CO2-neutral processes or store CO2 as negative emissions. As carbon will be a crucial building block of today's and future chemicals and fuels, it must be extracted and processed in a sustainable way. To this end, innovative materials for CO2 capture are being evaluated and their integration into a cycle analysed.

One focus will also be on the utilisation of waste materials for carbon capture, for example from mining or the steel industry. The most promising carbon capture materials will be coupled with production processes for carbon-based fuels and chemicals and the entire process chain will be analysed techno-economically. Such assessments will help to make decisions on the selection of the right technology and to develop better process integration.

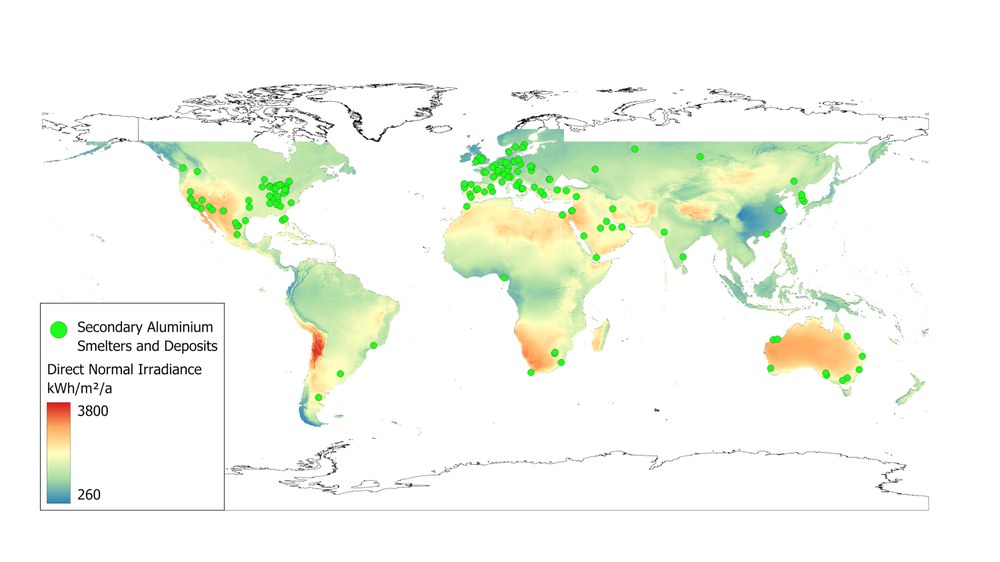

An important step in identifying which high-temperature processes are suitable for the utilisation of renewable heat is their systematic evaluation. On this basis, industries and global locations can be identified where technologies such as concentrating solar power can be used in a sustainable and economically viable way. This is part of the SOLINT project, which also aims to determine parameters such as the cost of renewable heat and the reduction of CO2 emissions.

The production of so-called green hydrogen is playing an increasingly relevant role in the ongoing energy transition. The energy carrier hydrogen can play a decisive role in many industrial sectors, as it is suitable as a fuel and as a seasonal energy storage medium for renewable energies. As an alternative production pathway to emission-intensive natural gas reforming, which is still the predominant technology, DLR researchers in the SOLINT project are focussing on the solar-electrochemical production of hydrogen.

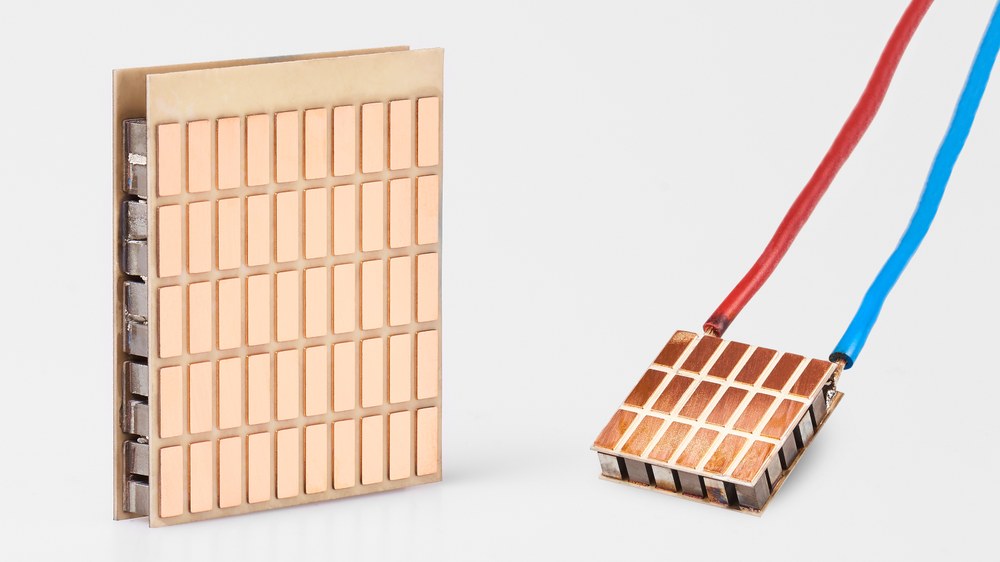

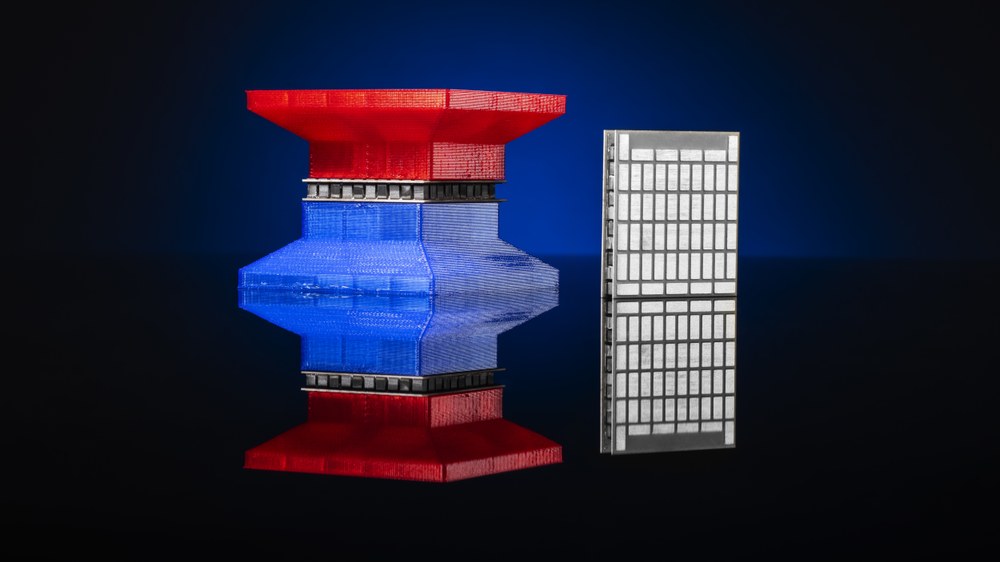

In this process, electricity is produced in a photovoltaic cell powered by concentrated solar radiation. This is fed into an electrolysis cell, where water is electrochemically split into hydrogen and oxygen. In this type of solar fuel production, the two coupled cells produce waste heat. The focus of the work carried out as part of SOLINT is on the integration of further processes in order to utilise the waste heat and thus exploit the sunlight as fully as possible. The project compares, evaluates and models various thermally coupled solar-electrochemical systems. The most promising concept will then be implemented in practice on a demonstration scale and tested experimentally at the DLR site in Cologne-Porz using the SoCRatus test stand and the High-Flux Solar Simulator.

The thermally coupled solar-electrochemical production of hydrogen aims to maximise the overall efficiency, which should drive the industrial implementation of green hydrogen as a fuel and energy storage medium in sunny regions.

Another topic investigated in SOLINT is fertiliser production. Synthetically produced fertilisers ensure that the world's population is fed. Unfortunately, the production of these fertilisers is a very energy-intensive process and causes large amounts of CO2 emissions every year. For this reason, we are analysing various fertiliser production methods and evaluating where synergy effects with other processes can be used and where the integration of solar process heat and process management that is as CO2-free as possible are possible and sensible. The entire production chain is considered. Analytical considerations are supplemented by laboratory experiments.

SOLINT has set itself the task of using the example of important industrial processes to demonstrate qualitatively and quantitatively how processes can be designed and coupled with each other in order to optimise the use of energy and product flows in terms of the raw material base and the primary energy required. Substances that are produced as by-products in one process can be valuable raw materials for other processes. Waste heat generated in one process can be utilised in other processes. Such synergy effects are being identified by DLR researchers as part of the project in order to develop sustainable production paths. In order to achieve this goal, the integration of solar radiation as an environmentally friendly energy source is also at the centre of the work.

Project | SOLINT |

|---|---|

Duration | 1.1.2023 - 31.12.2026 |

Project participants | |

Funding |

DLR-internal funding (Energy Programme Directorate)

|