ABraytCSPfuture

Coupling of air-operated CSP to carbon-neutral air-Brayton gas-turbine cycles to boost efficiency

Duration: 1.11.2022 - 31.10.2026

A proposal for a bright CSP future: The EU-funded ABraytCSPfuture project plans to develop a technology for air-operated concentrated solar power plants (CSP) coupled to carbon-neutral air-Brayton gas turbine power generation cycles. So far highly efficient air-Brayton combined power cycles used in traditional power plants involve fossil fuels combustion via pressurised air.

The target of the project is to achieve higher solar-to-electricity efficiencies, vital for competitiveness of CSP and non-reachable by either photovoltaics or molten salts and thermal oils.

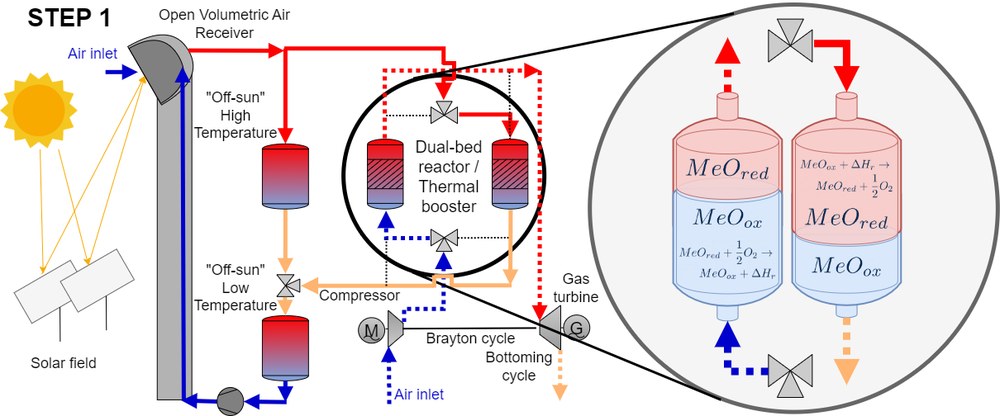

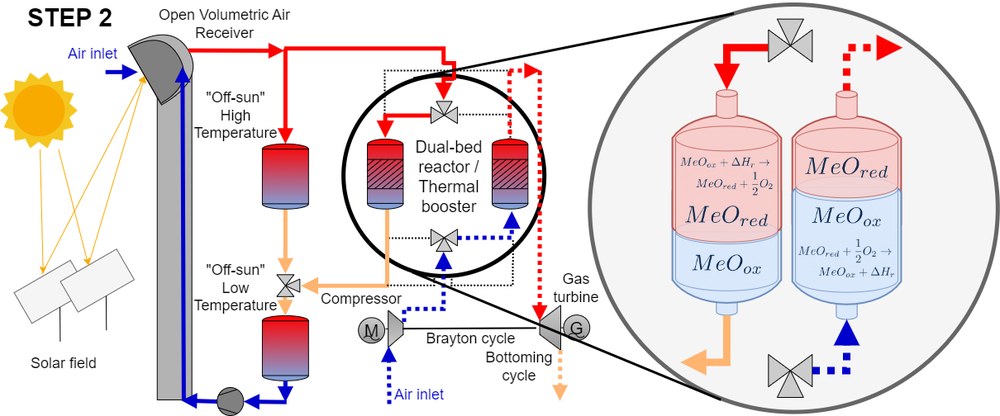

To achieve this, the project aims to demonstrate a first-of-its-kind compact, thermochemical reactor/heat exchanger design, that will transfer heat from a non-pressurised air stream to a pressurised one. It will also operate as a thermal booster, raising the temperature of the pressurised stream to the level required for operation of Brayton gas turbine cycles.

Heating ceramic structures

This innovative design will be comprised of non-moving, flow-through porous ceramic structures (honeycombs and foams) – made out of specific oxides prepared from cost-efficient, abundant and health-neutral raw materials. These oxides are oxygen compounds consisting in their simplest form of Oxygen and a metal (Me) cation exhibiting multiple oxidation states.

Hence, such oxides can reversibly transform between their oxidized (higher-valence, MeOox) and reduced (lower-valence, MeOred) state through chemical reduction-oxidation (redox) reactions in which electrons are transferred from the metal atoms to the oxygen ones and vice versa.

Depending on the kind of the metal, these reactions can be accompanied by significant endothermic (absorbing heat) and exothermic (releasing heat) heat effects. Specifically, under the supply of external heat (Q), for example from a concentrated solar thermal facility, the oxidized form of the oxide MeOox, releases a quantity of oxygen and transforms to its reduced state according to the generalized reaction scheme below. If this forward reaction is completely reversible, the thermal energy supplied to perform it can be recovered completely by the reverse reaction of the reduced state of the oxide with oxygen present in an air stream.

MeOox + (Q)

Essentially the solar heat is stored in the reduced state of the oxide, to be recovered on demand when the sun is not available. This oxide-based, two-step cyclic scheme is one among several so-called Thermochemical Energy Storage (TCES) approaches investigated for the storage of solar heat.

Furthermore, in the project ABraytCSPfuture the solar energy storage density of the CSP plant will be significantly increased by using similar structured redox oxide-based porous ceramics as the heat storage medium. In this way, the current sensible-only regenerative storage systems will be rendered to hybrid sensible-thermochemical storage ones, within the same storage volume.

Both these functionalities, thermal boosting and thermochemical heat storage, will be materialized by exploiting reversible reduction/oxidation reactions during heating/cooling of such oxides in direct contact with air.

The process

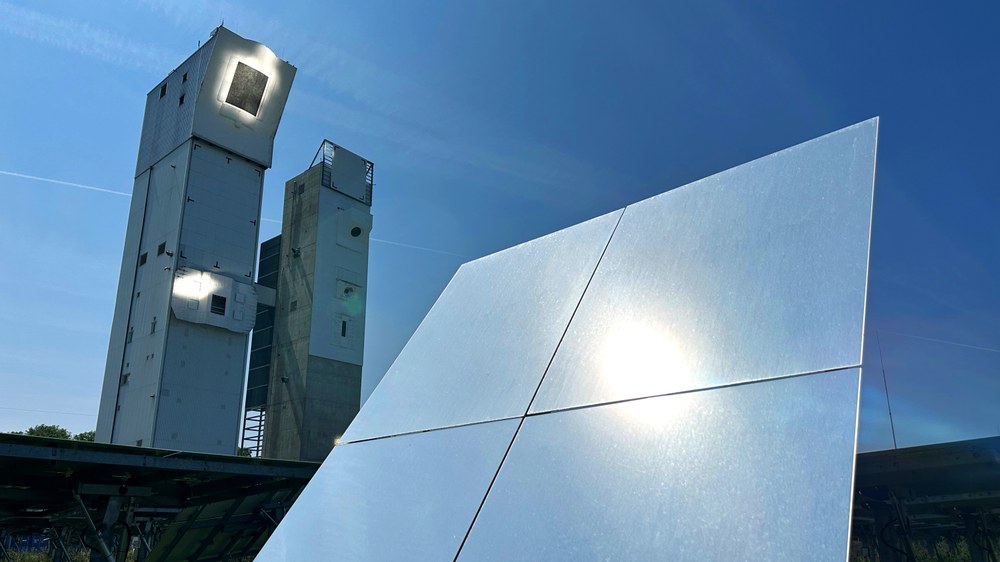

- Concentrated Solar Power (CSP): High-temperature air-based CSP together with Open Volumetric Air Receiver (OVAR)

- Thermochemical Energy Storage (TCES): High energy density dual-bed thermochemical reactor based on redox reactions

- Power Block (Combined Cycle): Air Brayton/Rankine Combined Cycle that achieves high thermal-to-electric efficiencies due to a dual-bed thermochemical reactor that operates simultaneously as a “thermal booster” based on the same redox reactions

- Renewable electricity generation based on solar energy – acceleration of the green transition with “a bright CSP future”

ABraytCSPfuture

ABraytCSPfuture

This technology is set forth by an interdisciplinary partnership spanning the entire CSP value chain, comprised of leading research centers, universities, innovative small and medium enterprises (SMEs) and large enterprises, including ancillary services providers and technology end-users.

More information on the project website:

Project | ABraytCSPfuture |

|---|---|

Duration | 1.11.2022 - 31.10.2026 |

Project participants |

|

Funding | Funded by the European Commission, through the HORIZON EUROPE, RIA – Research and Innovation Actions programme HORIZON-CL5-2021-D3-03, under grant agreement No 101084569. |