CemSol

Development of a calcium looping (CaL) process coupled with cement production

Duration: 1.10.2021 - 31.3.2025

Solar thermal plants use mirror systems to concentrate sunlight and generate high energy densities. Depending on the type of plant, heat can be provided at temperature levels of over 1000 degrees Celsius. Solar thermal power plants use the high temperatures to drive a steam turbine to generate electricity. The thermal energy contained in concentrated sunlight can also supply industrial plants with process heat.

In the CemSol project, researchers from the DLR Institute of Future Fuels are investigating how a solar thermal plant can supply the high-temperature heat for the calcination of calcium carbonate, an energy-intensive sub-step in the production of cement. The project aims to show that a solar-heated calcination unit is technically feasible on an industrial scale and can be operated economically. By using solar thermal energy instead of fossil fuels, large amounts of CO2 emissions can be avoided.

The Calcium-Looping (CaL)

The calcination of limestone is a very energy- and emission-intensive process on an industrial scale, which is used, among other things, in cement production or in the production of aluminium oxide. It usually involves fossil-fueled, thermal processes in which minerals containing calcium and magnesium carbonate are dehydrated or decomposed.

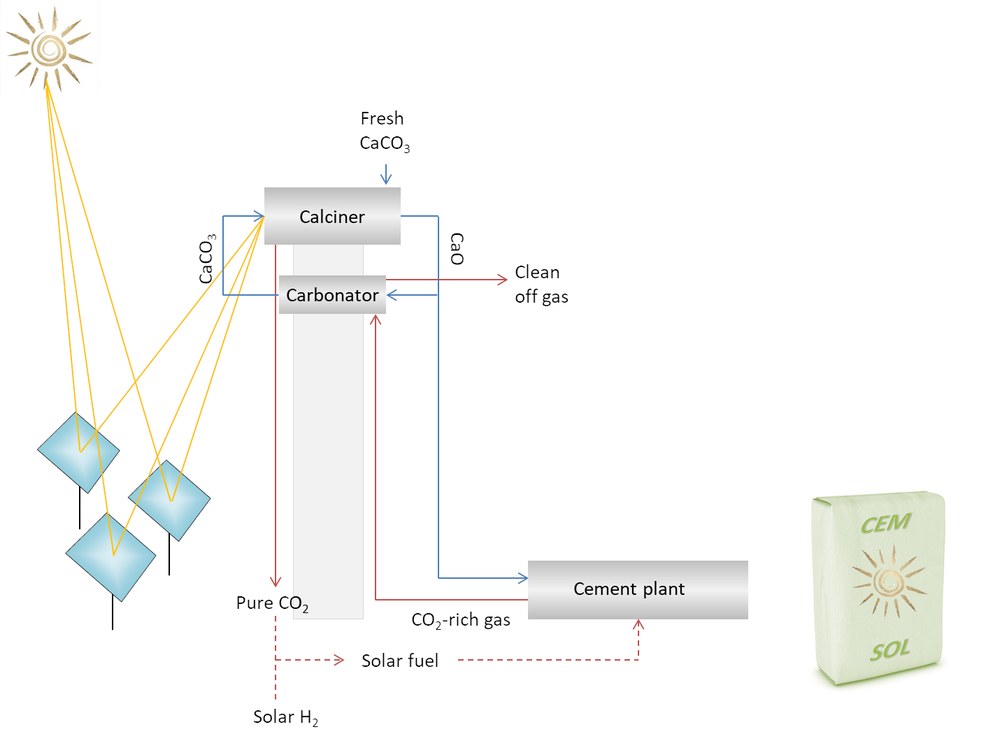

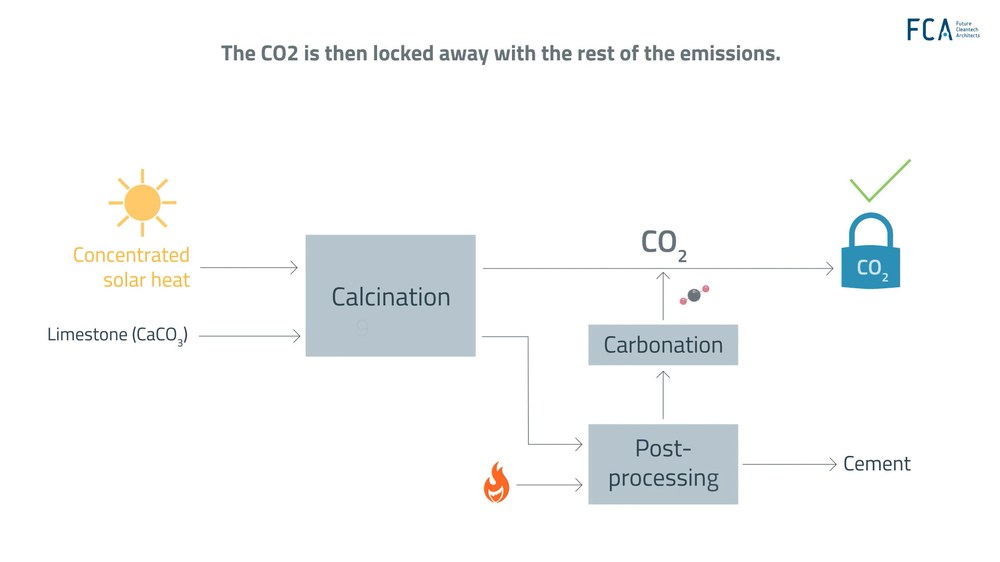

In the CemSol project, the researchers want to develop a calcium looping (CaL) process coupled with cement production. This looping process consists of two steps:

During calcination, solid calcium carbonate (CaCO3), in this case cement raw meal, which consists mainly of limestone, is fed into a calciner. There it is heated to 900 degrees Celsius with the help of high-temperature solar heat to thermally decompose into gaseous carbon dioxide (CO2) and solid calcium oxide (CaO). Some of the CaO produced can now be used to make cement. The CO2 produced during calcination is extracted and purified so that it is suitable for storage or further processing into chemicals and fuels.

In the second step, carbonation, the other part of the CaO is taken out of the calciner and fed into the carbonator. It cools down to about 650 degrees Celsius and is brought into contact with the CO2-rich waste gas from the cement plant, so that CaO and CO2 react to form CaCO3. The resulting CaCO3 returns to the calciner and the cycle begins again.

Transfer to the cement industry

In the project, the researchers are looking at the entire calcium looping as a process and its coupling to the cement production plant. For this purpose, they are creating energy and mass balances as well as emission balances. The core of the project is the experimental verification of the concept. This begins with material investigations to estimate the carbonisation potential of cement raw meal. The operating conditions and quality of the raw material are of great interest.

Based on the results of the investigations, the researchers design a suitable reactor concept for the carbonator and a scale-up concept for the solar calciner. Their operation is then demonstrated and the efficiency determined. Important criteria here are high-temperature stability, thermal shock resistance, efficient operation and product quality.

The project focuses on the use of the technology in the cement industry. However, the researchers are also investigating to what extent the technology can be used for other industries with high CO2 emissions. A techno-economic study will provide indications for the industrial-scale application of such a technology in reference processes, for example amine scrubbing and oxyfuel processes.

Project | CemSol |

|---|---|

Duration | 1.10.2021 - 31.3.2025 |

Project participants | |

Funding | The project is funded by the German Federal Ministry for Economic Affairs and Climate Action. |

Multimedia

Video: CemSol project - low-emission cement production through solar calcination

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

Future Cleantech Architects (FCA)