FlowPhotoChem

Sustainable production of chemical base materials from water and carbon dioxide using concentrated solar radiation

Duration: 1.6.2020 - 30.9.2024

The EU project FlowPhotoChem has succeeded in developing a modular, sunlight-operated system for the production of sustainable chemicals and operating it in practice in the High-Flux Solar Simulator at the DLR site in Cologne-Porz.

FlowPhotoChem

The project focussed on the solar production of ethylene, an important base material for the chemical industry, which is used for the production of the plastic polyethylene, among other things. In addition, relevant quantities of other valuable products such as acetate, ethanol and propanol are produced.

Step by step to the target product ethylene

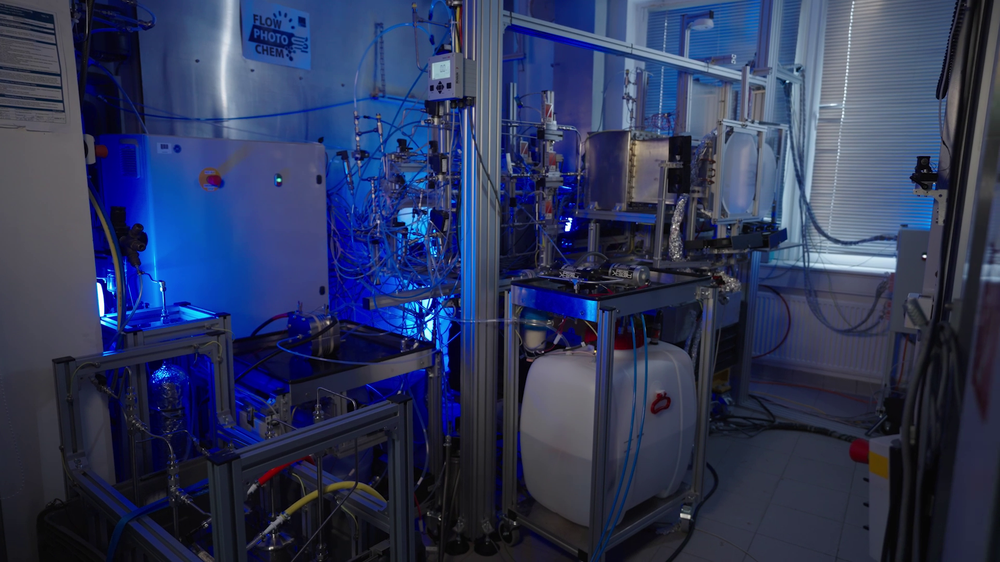

The system consists of three reactor modules connected in a cascade, in which different steps take place on the way from the starting materials water and carbon dioxide to the target products:

- In the first, photo-electrochemical reactor module, water molecules are split using concentrated solar radiation, producing hydrogen and the by-product oxygen.

- The hydrogen produced is fed into the second reactor module together with carbon dioxide. There, also under concentrated solar radiation, carbon monoxide is produced photocatalytically or photothermally.

- Finally, this carbon monoxide is fed into a third, electrochemical reactor in which the target products are formed using electrical energy, which can come from photovoltaic systems.

Setup and tests in the Cologne High-Flux Solar Simulator

The Institute of Future Fuels was responsible for the design and construction of an operational overall system and the integration of the three reactor modules mentioned. These were developed by specialised project partners. The École Polytechnique Fédérale de Lausanne (EPFL) and its spin-off SoHHytec supplied the photo-electrochemical reactor module, while the Polytechnic University of Valencia (UPV) built the second reactor module. The electrochemical reactor module was developed in Hungary by the company eChemicles with the support of the University of Szeged (SZTE). The Institute of Future Fuels supported the development of the reactor modules from a system perspective with the help of system models and was able to ensure compatibility of the reactor modules in close cooperation with the project partners.

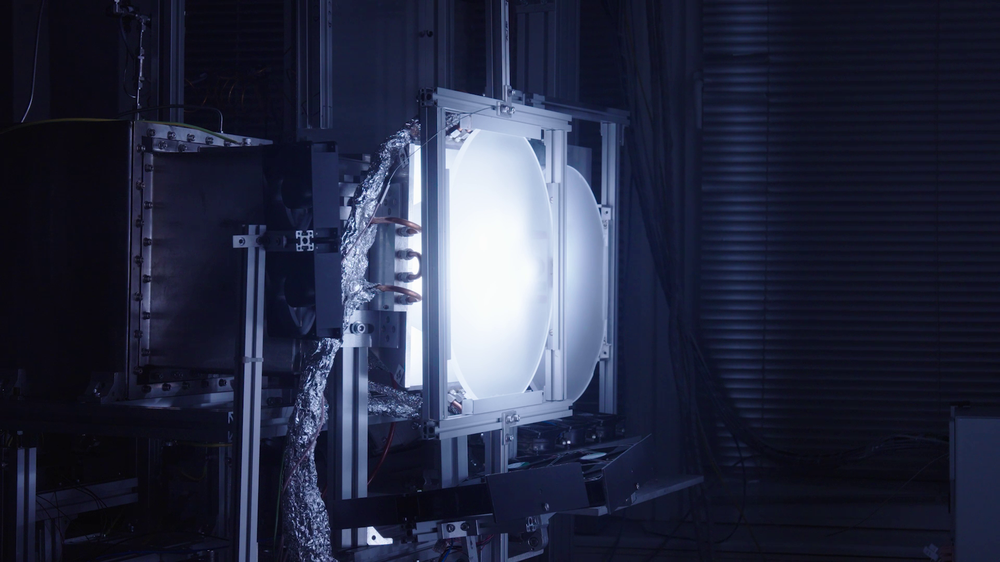

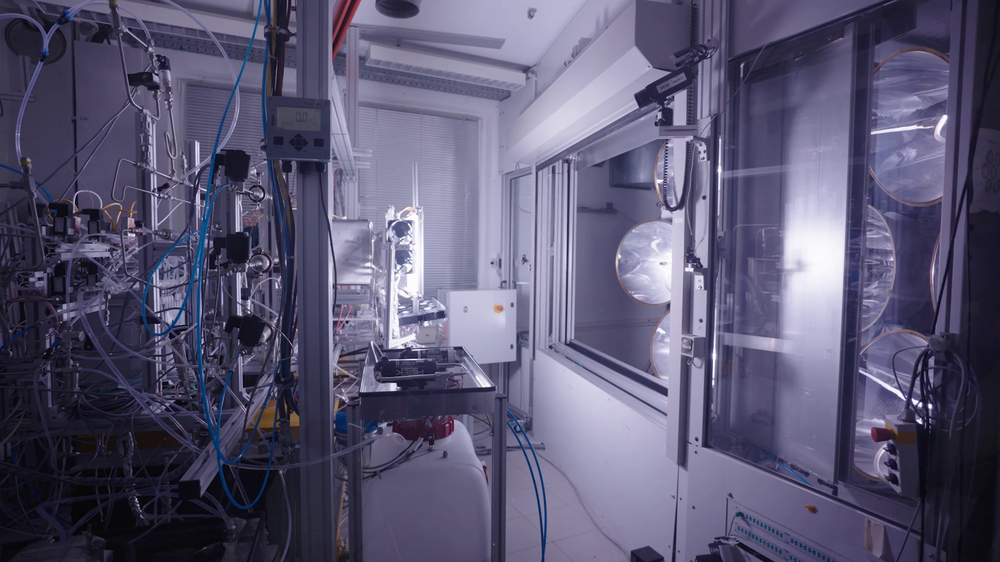

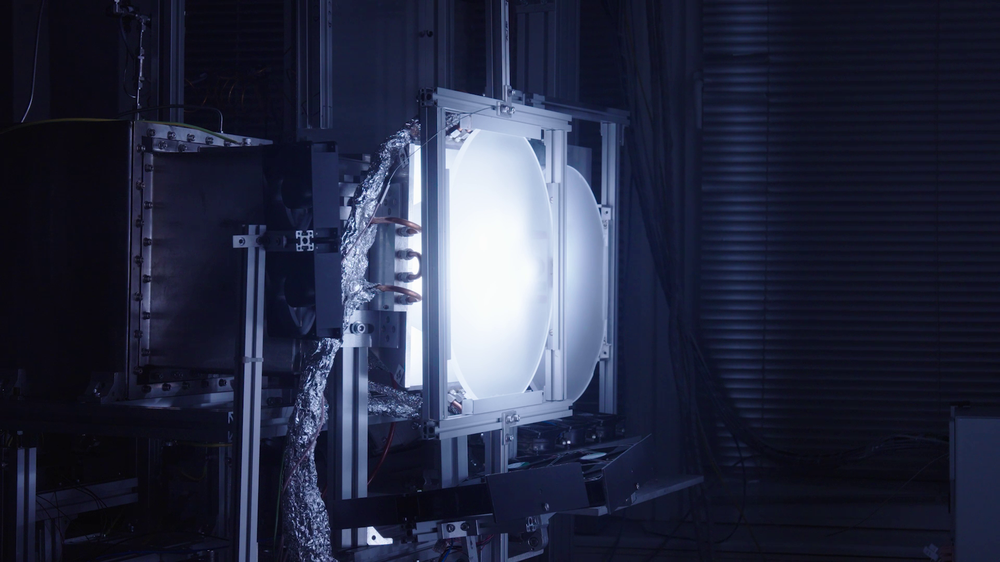

The entire system was set up and commissioned in DLR's High-Flux Solar Simulator. The high-power radiators supplied the concentrated - in this case artificial - solar radiation required to operate the first and second reactor modules. Its use made it possible to carry out the experiments regardless of the weather.

One particular challenge was to ensure a flat intensity profile on the surfaces of the reactor modules to be irradiated. Researchers and engineers from the Institute of Future Fuels developed suitable optical elements for beam shaping and placed them between the lamps of the solar simulator and the reactor modules.

Irradiation with up to 700 suns

In the final one-week experimental phase, the researchers were able to successfully demonstrate the solar production of the target product ethylen as well as other hydrocarbons and energy sources, thereby achieving an important milestone in the FlowPhotoChem project. The practical experience gained also enabled the Institute of Future Fuels to further expand its expertise in the operation of complex experimental setups with comprehensive measurement and control technology. The knowledge gained represents an important basis for the further development of this modular approach to the sustainable and climate-neutral production of chemicals and energy sources.

Project | FlowPhotoChem |

|---|---|

Duration | 1.6.2020 - 30.9.2024 |

Project participants | |

Funding | This project has received funding from the European Union’s HORIZON 2020 research and innovation programme under grant agreement No 862453. The material presented and views expressed here are the responsibilities of the author(s) only. The EU Commission takes no responsibility for any use made of the information set out. |

Website |

Multimedia

Video: DLR project FlowPhotoChem - Sustainable production of base chemicals from water and carbon dioxide using concentrated solar radiation