Temperature record in the MOPUW, the hottest thermal oil plant in the world

- In tests on new types of heat transfer fluids, a new global temperature record was set.

- Together with industrial partners, the researchers at the Cologne MOPUW were able to demonstrate the functionality of the entire system in continuous operation at up to 470 degrees Celsius.

- Important insights were also gained into the pump technology used.

- The foundations have thus been laid for further test series with even higher temperatures.

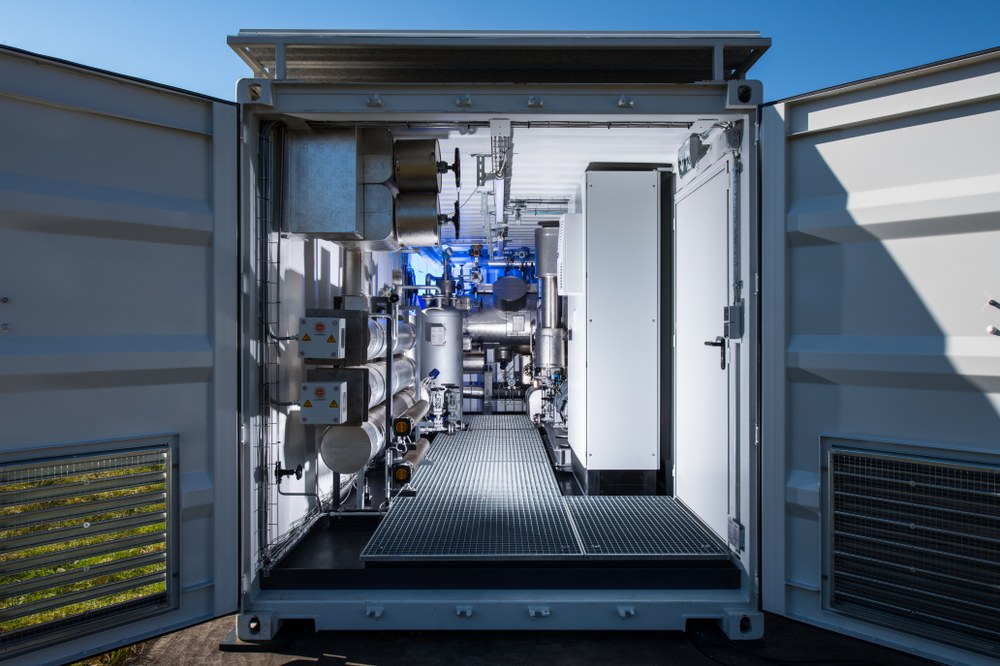

The Mobile Pump and Heat Transfer Fluid Test Stand (MOPUW) enables the demonstration and research of new types of heat transfer fluids for solar thermal power plants and industrial plants on a pilot plant scale. In the completed first system demonstration with a high-temperature silicone oil, DLR, in cooperation with the participating industrial partners, demonstrated the functionality of the entire system at temperatures of up to 470 degrees Celsius in continuous operation.

HELISOL® XLP, a new silicone oil developed by WACKER Chemie AG, was used as the heat transfer fluid in the MOPUW test stand. In combination with a pump from DICKOW Pumpen GmbH of the NMX series, it was continuously pumped around the system at temperatures between 450 and 470 degrees Celsius.

Really hot oil

According to the researchers' knowledge and according to the operating parameters, no other plant in the world can be operated with a thermal oil at such high temperatures. The industrial partners involved in the MOPUW test stand are the pump manufacturer DICKOW, the plant manufacturer heat 11, the chemical company WACKER and TÜV NORD.

Close monitoring

To determine how temperature-resistant the heat transfer fluid is, the researchers from the Institute of Future Fuels operated the test stand for a period of 3,000 hours at 450 degrees Celsius, another 1,000 hours at 460 degrees Celsius and finally 1,000 hours at the peak temperature of 470 degrees Celsius. During the test operation, the stability of the HELISOL® silicone oil was confirmed by regular sampling. To this end, a series of tests were carried out, including the analysis of gases that can form in the system over time. In addition, WACKER was able to determine the chemical age of the fluid in laboratory tests during operation on the basis of certain parameters. These indicate the degree to which the long siloxane chains that make up the HELISOL® XLP fluid crosslink with each other under the influence of the high operating temperature. As the degree of cross-linking of a silicone fluid increases, the viscosity can increase, leading to problems in plant operation, including increased energy requirements for the pumps. In a CSP solar thermal power plant with a maximum operating temperature of 425 degrees Celsius, the application limit or service life of the fluid is over 25 years, according to the manufacturer.

The heart of the plant, a new NMX high-temperature pump from DICKOW, was also qualified during operation and tested under extreme conditions. In particular, the heavily stressed seals and the smooth running of the unit were meticulously analysed. Just like the HELISOL® XLP heat transfer fluid, the pump also passed the stress test.

Due to the very good test results, the project partners consider even higher operating temperatures of up to 480 degrees Celsius to be technically feasible. An important foundation has thus been laid for future projects and further test series.