LamTA

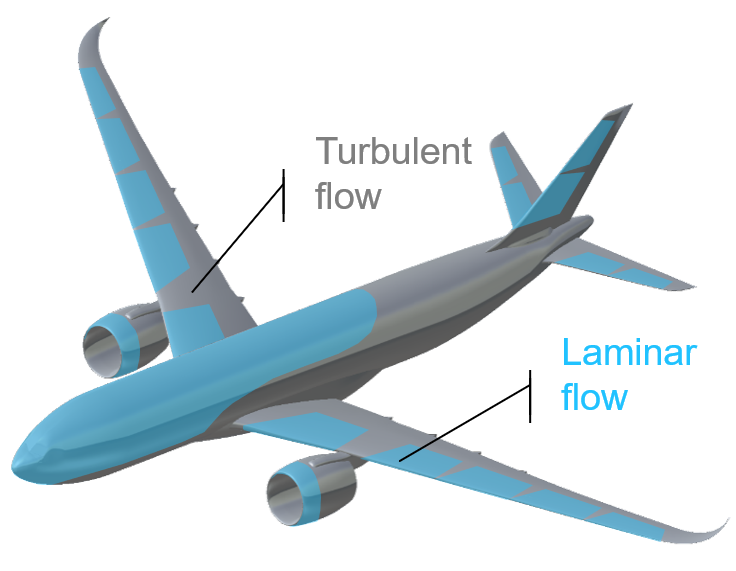

The objectives of the European Green Deal on emission neutrality in aviation cannot be achieved without significant savings in energy requirements. Laminar surfaces can significantly reduce drag in flight and increase efficiency. However, the prerequisite is that the aircraft is tailored to the best possible implementation of these technologies.

In the DLR project LamTA (Laminar Tailored Aircraft) project the maximum potential of laminar technologies to reduce the energy consumption in flight is determined on the basis of a long-haul aircraft designed for laminar control from the beginning of the design chain, considering previous knowledge and the current state of the art. The savings potential of all wetted components is already considered in the preliminary design, in particular the previously unused fuselage surface. Design and manufacturing processes are further developed and are incorporated into the aircraft design with regard to special challenges related to laminar flow, such as the avoidance of surface disturbances and the integration of suction systems in interaction with wing de-icing and high-lift systems along with targeted experimental analyses. This enables the design of a laminar tailored long-haul aircraft specifically tailored for laminar technologies. The evaluation of this design against a turbulent reference provides the savings potential of laminarization and also includes maneuverability and handling quality considerations. In order to answer open questions in the field of laminar control in flight tests at usual cruise Mach numbers above 0.8 and thus to improve the design methodology as well as validation of future laminar concepts, measurement techniques are further developed in LamTA and a suitable experimental setup is designed. Furthermore, the aerodynamic simulation capability for laminar and transitional flows is being further developed in the TAU flow solver developed by the DLR Institute of Aerodynamics and Flow Technology and, in order to maintain competence in the long term, is being transferred to the next-generation flow solver currently being developed with Airbus and ONERA.

Through the planned work, LamTA not only contributes significantly to the evaluation of laminar control as a key technology for emission-neutral air traffic, but also demonstrates and consolidates DLR's outstanding position in multidisciplinary laminar aircraft design and technology integration. In addition, significant contributions will be made to achieving the goals defined in the DLR aviation strategy for the European Green Deal and the 2025 HGF milestone "NLF/HLFC technology optimized and integrated into overall aircraft".

The scientists of the Institute of Aerodynamics and Flow Technology make significant project contributions in the areas of laminar aircraft design, simulation and technology assessment. Furthermore, they pursue long-term research and development goals in simulation and measurement technology as well as technology integration.

Project | LamTA - Laminar Tailored Aircraft |

|---|---|

Term | 1/2023 – 12/2026 |

Partners |

|